Supplier Selection Process: Steps, Methods, Best Practices

Learn the supplier selection process - key steps, criteria, best practices to choose reliable, cost-effective partners for your business.

200+ buyers trust Torg for sourcing

All businesses desire smooth operations. It's not out of the question. But that's mostly dependent on one aspect: who they're buying from. The choice of who to buy from essentially decides if your supply chain is still strong or falls apart when something goes wrong. And it's not merely picking the cheapest quote. You have to factor in supplier capacity, production capacity, and financial stability, too.

Procurement managers and supply chain teams deal with this every day. Choosing suitable suppliers, checking supplier data, and avoiding surprises like late deliveries or poor quality issues. In this guide, we’ll break down how the supplier selection process really works: from spotting potential suppliers to running proper supplier evaluation and negotiating deals that actually make sense. The goal is for you to know how to evaluate suppliers effectively, risk mitigation, and find the right suppliers that will be appropriate for your business' long-term strategy.

What is the Supplier Selection Process?

The supplier selection process is how businesses decide who they should purchase from. But there's more to it than that. Procurement teams aren't simply going for the lowest price; they review everything from supplier capacity and financial health to whether a supplier can actually keep pace when demand is high. It's similar to hiring someone. You don’t just pick the first name that shows up on a list. You’d want proof they can deliver, stick to timelines, and actually meet the standard.

In truth, supplier selection starts the moment a company realizes there’s a gap to fill—whether that’s components, materials, or outside help. Next is a combination of setting supplier selection criteria, looking for prospective suppliers, and comparing their proposals. And after final selection, supplier relationship management (SRM) comes in to make sure everything goes smoothly and long-term trust actually forms.

The Importance of Supplier Selection Process

Try to think about your supply chain like it's a spider web. Break one thread and the entire thing trembles. This is only to say that one poor decision can result in delayed deliveries, low quality, or even supply chain disruptions brought about by things no one expects, such as natural disasters or a supplier suddenly going out of business. That is why businesses should have a good, data-driven method of evaluating suppliers, and not just selecting whoever appears most inexpensive on paper.

A great process makes it all predictable. Procurement teams can contrast the responses of suppliers, quantify risk factors, and make better calls in line with the company's business intentions. It’s less about control, little more about trust. When everyone pulling the strings moves in the same rhythm, choices stop dragging and start flowing. Over time, solid supplier relationships pay off; the potential partners don’t slow your growth, they grow beside you.

🌐 Choosing suppliers can make or break your business. Torg connects buyers and suppliers worldwide, offering verified partners and streamlined sourcing. 👉 Sign up today to simplify the supplier selection process, ensure quality, reduce purchase risk, and build long term relationships across your supply chain.

The 7 Steps in the Supplier Selection Process

Each procurement process step counts in the process, and in some way, each contributes to the next. So, here's a better glance at how procurement professionals actually conduct the supplier qualification process.

1. Identifying Business Needs

It all begins here. You take a seat and determine what your business actually requires — not what it desires, but what it needs to work. Ask the easy and hard questions. "What are the specs? The volumes? Any quality requirements we can't skimp on?"

Essentially, this is where you identify your must-haves and nice-to-haves — production capacity, rules for regulatory compliance, turnaround time, and so forth. Some companies pursue cost efficiency. Others? Supply chain resilience or sustainability. It changes. Business priorities do that, particularly when markets become unstable or when your business is scaling quicker than anticipated.

2. Supplier Identification and Market Research

Now that you know what you're searching for, it's time to go searching for suppliers. That's when you get into databases, browse through trade directories, or even call some industry contacts. Occasionally, you might find hidden gems in your existing vendor list; other times, you might find new suppliers at expos or through referrals.

By now, it's more probable that you'll throw the net far. You desire possibilities. In fact, plenty of them. Don't miss the regional or sustainable supplier evaluation either. They tend to rescue you from logistics troubles later on.

Get the information through open calls or prequalification forms. The aim is to know who there is before getting too detailed.

3. Request for Information (RFI), Proposal (RFP), and Quotation (RFQ)

This section becomes formal. You have a list, now you require facts. You will issue:

- RFI — that’s when you’re just figuring out who can actually deliver.

- RFP — when it’s time for the details, the how and what of their offer.

- RFQ — numbers, deadlines, the small print that seals the deal.

Some projects call for one document. Others demand three. Sometimes, you mix them up just to get it right. What truly matters isn’t the format but the precision. Your paperwork should spell out expectations: compliance rules, contract terms, evaluation grounds. Miss that, and suddenly your comparisons make no sense—apples versus coconuts, quite literally.

Request a Bulk Order Quote

Simple ordering, transparent pricing, delivered straight to your door

4. Supplier Evaluation and Shortlisting

Now we're down to comparison time of the shortlisted suppliers. You've got the answers; you put them side by side. You grade them, rank them, debate a bit, perhaps rerun the calls. Every supplier is measured by the same standard with cost, quality, certifications, history, and overall fit.

Many procurement teams go ahead to the supplier facilities or arrange for supplier compliance audits just to ensure what's documented in those proposals. You might be surprised to find that quite often the paperwork appears impeccable, but the installed setup says otherwise.

Ultimately, you narrow it down to the ones that meet your minimum requirements or better still, those who share your vision long-term.

5. Supplier Selection Decision

Here is the decision-making phase — the one that tends to cause boardroom wars. Procurement, finance, key stakeholders, and operations people tend to have their say. Some employ a supplier selection matrix; some just use scoring sheets or weighted averages.

But the logic is the same: balance cost, quality, and risk. If you’re smart about it, you’ll diversify too. One supplier for core materials, another for noncritical components. Because no one wants all their eggs in one basket, especially when global supply chain management can snap overnight.

The final pick isn’t always about best price. It’s about reliability and ensuring alignment with your business strategy.

6. Negotiation and Contract Award

Pricing, timelines, payment terms—everything’s on the table. You talk confidentiality, you plan for the “what if it all goes sideways” moments.

Thoughtful procurement people plan ahead. They include review periods, escalation routes, and even force majeure agreements on things such as worldwide interruptions. Contracts are not pieces of paper; they are risk management methods in disguise.

Also, from the first day, consider supplier relationship management. Have supplier performance measurement metrics reviews in place. Make provision for ongoing improvement. Small issues are easier to tame before they turn into full-blown chaos.

7. Performance Monitoring and Continuous Improvement

Actual work begins once you sign. The suppliers must be checked up on from time to time. You monitor such things as delivery precision, speed of supplier response, quality levels, and even the way they deal with criticism. When it drops, you tackle it. Not in a rude manner, but constructively, either by corrective measures or improvement plans.

Give it time and the pattern shows itself. Those who listen, improve, and act on feedback stay. The rest? They slowly disappear from the picture. That’s the quiet truth of procurement. Supplier performance tracking isn’t policing. Its focus is on the partnership. Because the stronger the collaboration, the more resilient your supply chain becomes.

What Are Supplier Selection Criteria?

Selecting suppliers is not rocket science, but it's not luck either. You would like someone steady, consistent, and unfazed when things get rough. Reliability. Quality. Grit. Strip it down to that. Now, what really matters? Let’s break it into the things that move the needle.

1. Cost and Total Value

Everybody's all about price initially, but the truth of the matter is, the lowest price isn't always going to be the best value. You need to be thinking of the bigger picture: the overall cost, shipping, downtime, quality assurance, and even the hassle you'll steer clear of down the road. In essence, a supplier that may be "costly" on paper could end up saving you money in the long term. That's where you begin to realize total value rather than numbers.

2. Quality and Capability

This one’s pretty straightforward. If a supplier cannot provide your required quality standards, the rest is inconsequential. Inspect supplier capabilities, certifications, quality systems, inspection arrangement, and rework or defect handling. You’re not being picky; you’re being practical. A supplier who maintains consistent quality keeps your reputation intact and prevents chain reactions of issues down the line.

3. Delivery and Flexibility

On-time delivery may seem straightforward, but in fact, it's where so many deals go wrong. Is your supplier able to cope with pressure? What if there's an unexpected spike in orders, or a port closure? Great suppliers prepare for this, they've got buffer stock, backup systems, and adaptable logistics. Some way or another, it's those who prepare for anarchy that turn out to be your most reliable collaborators.

4. Financial and Operating Stability

You'd be amazed at how many possible suppliers seem wonderful until you start looking into their books. A wobbly financial foundation is a time bomb. Procurement teams usually miss this aspect, but it's one of the best indicators of a supplier's long-term potential. When a partner is financially healthy, it indicates they can weather disruptions and continue delivering. Apparently, that's the kind of unobtrusive strength you want behind your supply chain.

5. Sustainability and Compliance

This is gaining more traction now and rightly so. A supplier who is not compliant with regulatory rules can prove to be a liability. It's not about fines or paperwork. Your brand reputation is on the line, so look for partners who share a commitment to ethical sourcing, safe labor practices, and environmental responsibility. Basically, if they care about sustainability, it is likely they will care about your standards as well.

Best Supplier Evaluation Methods

With your supplier evaluation criteria set up, how exactly do you measure who's the best? Procurement teams don't flip coins. They use established supplier evaluation techniques, some simple, some more math-intensive. Below are some examples of supplier evaluation methods in procurement:

Weighted Point Method (Scoring Model)

This one is essentially the default in procurement. Assign weight where it matters most — maybe quality takes 30%, cost 20%, delivery 15%. Then score every supplier against those numbers. Multiply, total, and the result appears: a weighted score that tells you, in quiet math, who actually measures up. The highest number usually goes to the top supplier.

Others prefer it because it's flexible and crystal clear. Easily modify priorities based on business objectives. But, of course, the trick is that the data is scored by humans — and humans are not always objective. A bit of calibration among evaluators prevents things from getting unfair.

Categorical Method

Consider this a quick sort. You simply tag suppliers as "excellent," "good," "acceptable," or "unacceptable" on each box. The ones that fail the important boxes get eliminated. It's easy, really. No figures, no equations, just sorting. Great for initial screening, but not so penetrating when you want in-depth comparisons.

Cost Ratio Method

Now, this is more numerically focused. You're essentially pitting cost vs. performance such as cost per quality point or cost per delivery success. The equation is simple enough but can work against you if you prioritize cheapness too much. Where the failure of your product or downtime is extremely expensive in certain industries, the cheapest supplier isn't necessarily your best bet.

Total Cost of Ownership (TCO) Analysis

TCO goes deeper. It doesn't simply inquire, "What's the cost?" It inquires, "What's the true cost over time?" And that encompasses logistics, warranty, defect rates, disposal, and even compliance. For instance:

TCO = Purchase Cost + Operating Cost + Maintenance + Disposal Cost

A supplier may cost you more upfront but keep you out of trouble later — reduced defects, quicker service, smoother operations. That's true value, not merely figures on an invoice.

Analytical Hierarchy Process (AHP)

This one seems scary, but it's really reasonable. You create a hierarchy — top criteria, subcriteria, and alternatives — and then compare all of them pair by pair. Each comparison yields a ratio (such as 3:1 if quality > cost), and from those ratios you derive weights. The math lowers the bias and provides a data-driven, structured decision. It's a bit of a process, but clearly it does work.

Supplier Scorecard / KPI-Based Assessment

After you begin dealing with suppliers, scorecards become your reality check. Keep an eye on the numbers like delivery times, defect rates, how fast they reply when things go wrong. A KPI dashboard does the watching for you. Give it a while, and patterns start speaking. Some suppliers rise; others stumble. It’s not about a single vendor scorecard system, it’s about seeing performance unfold in real time.

Supplier Audits and Site Assessments

Occasionally you just need to see it for yourself. A site audit demonstrates to you what spreadsheets can't, that is, the real production floor, labor pool, safety protocols, and if those ISO certificates are genuine or merely window dressing. In some way, touring a facility informs you more about a supplier's dependability than does any report.

Supplier Selection Best Practices

Selecting the proper supplier isn't a once-done task. It's an ongoing process. The best teams approach it as a partnership, not an order for purchase. The following are some practical, real-world practices that keep supplier selection strong and future-proof.

1. Engage Everyone Early

Don't make supplier selection a one-department affair. Procurement can't do it alone, actually. Get quality control, operations, finance, legal, even R&D in on it if they have skin in the game. Each has a different perspective and that combination of viewpoints catches what one team might overlook. There's just something about when everyone's included from day one that makes the decisions make sense.

2. Define Clear and Measurable Criteria

Before you even issue an RFP, take a seat and define what is important. Set down your supplier selection factors (quality, speed of delivery, price, sustainability, compliance) whatever your priorities are. Weigh them if you can. Essentially, definition upfront eliminates bias later. You can't quantify what you never defined.

3. Verify, Don’t Assume

A supplier selection process deploys a huge amount of a firm's financial resources. That's why make it a habit of always verifying things. Also, a good supplier on paper isn’t always good in real life. Request samples. Ask for certifications. Conduct a site visit if possible, see the machines, talk to the people, smell the floor (yes, that’s a thing). It’s one thing to read “ISO certified” and another to see how that actually plays out in daily operations. Somehow, those visits reveal things numbers don’t.

4. Begin Small and Monitor Everything

Don't commit to a multi-year contract without feeling the waters first. A trial or pilot order demonstrates how they react under pressure with delivery lead times, communication, handling of problems, and consistency. Get it simple but pay close attention. Track performance with scorecards, KPIs, whatever keeps the numbers visible like delivery on time, defect rates, and response speed. Let the data speak. When the facts show up, arguments fade.

5. Make It Flexible and Forward-Facing

Nothing is stagnant. Markets change. Suppliers are sold on and off. Regulations become stricter. So, review suppliers annually or biennially. Practice dual sourcing when necessary. Always have a Plan B. Technology also assists. A good supplier management system can hold information, automate scorecards, and have some supplier risk analysis before they strike. And most importantly, maintain open communication and develop closeness. When both parties communicate freely, surprises diminish and trust builds.

Common Challenges in Supplier Selection

Even veteran procurement teams make mistakes occasionally. Problems lurk around every corner. That's why spotting the common pitfalls early saves future headaches. Let’s look into the common challenges of supplier selection:

Lack of Data Transparency

There are some good potential suppliers on paper, but the facts? Shaky or inconsistent. At times, the information is too glossy or omits critical details. That makes it extremely difficult to assess suppliers. Essentially, you need proof — certificates, historical performance reports, site audits — anything to support claims. A good and successful supplier selection process works wonders here.

Bias in Evaluation

It happens more than you’d think. A team member favors a familiar vendor. Or someone assumes past performance automatically guarantees future reliability. Subjectivity creeps in. To counter this, stick to predefined selection criteria, consider a blind scoring system, and involve multiple evaluators. Somehow, having more eyes on the process reduces favoritism and keeps the decision data-driven.

Overreliance on Cost over Quality

Sure, juggling cost issues. But pursuing the lowest price in isolation? That can be catastrophic. Late delivery, low quality, or bad after-sales service can pay ten times over a high initial price. Supplier assessment methods must weigh cost against overall value, quality, lead time, and risk elements. Simply put, cheap isn't always clever.

Global Supply Chain Risks

Going global isn’t without its headaches. Currency swings, political shake-ups, customs jams, tariffs, even storms can throw a wrench in the works. Even a top-notch supplier can stumble when the world interferes. That’s why procurement teams hedge their bets with dual sourcing, regional partners, or anything to keep operations running and potential risks in check.

Supplier Financial Failures

Occasionally, a supplier appears strong until the figures reveal otherwise. Cash flow problems, credit issues, or insolvency can cause shabby practice, delayed delivery, or breakdown. Financial stability is an essential supplier choice criterion, therefore ensure you examine statements, have a vendor rating system, and solvency prior to final choice. Fundamentally, the finance aspect is as significant as operating performance.

Ready to Find the Best Suppliers with Torg?

If you’re looking for a faster, smarter way to find suppliers, Torg is a great place to start. It’s an AI-powered B2B marketplace and sourcing platform built specifically for buyers and suppliers, connecting reliable, verified suppliers with legitimate decision-makers without spending weeks digging through search results or cold emailing factories.

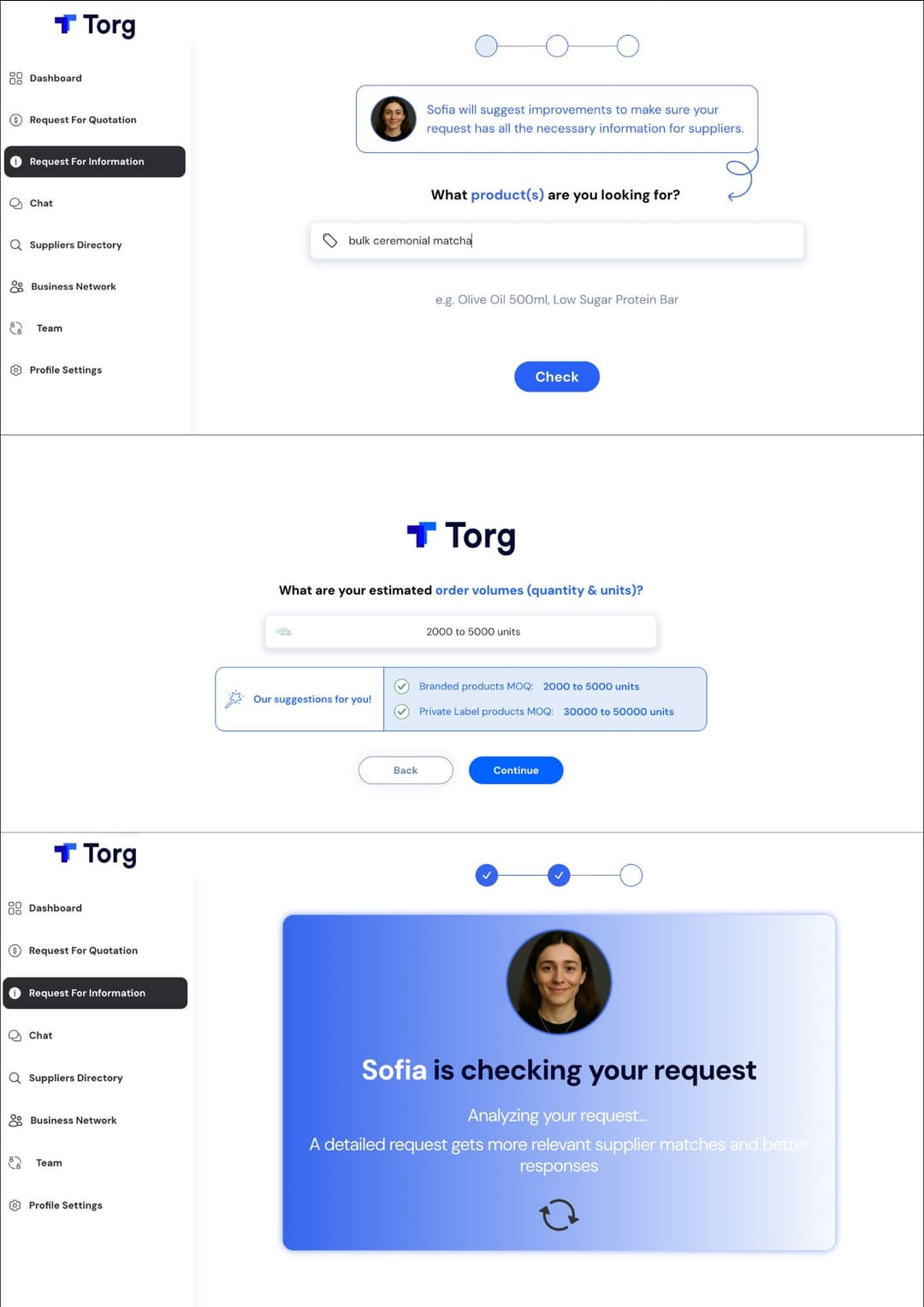

Here’s how to get going:

1. Sign Up—It’s Free and Quick

Create a free account here. No long forms or complicated onboarding. Just a few clicks and you’re in.

2. Search for What You Need

Type in your exact product such as "olive oil," "organic sauces," or "private label frozen meals." The more exact your keywords, the better your matches will be.

3. Add Your Order Volume

Whether you need 500 units or 10,000, including a rough volume of what you need helps Sofia find suppliers that fit your scale.

4. Mention Special Requirements

Need organic certification? How about plastic-free packaging? Add specifics such as allergens, style of packaging, or ingredient selections as this eliminates the suppliers immediately.

5. Let Sofia (Torg’s AI Assistant) Get to Work

Torg’s built-in AI, Sofia, scans thousands of verified suppliers to find the most relevant ones for your request. You’ll start getting suppliers based on your multiple criteria without lifting a finger. You can view the results on the Request for Information section from your dashboard.

With Torg, you’re not just blindly sending emails to random producers. You’re tapping into a focused B2B tool designed to connect serious buyers with high-quality suppliers almost instantly. It's very ideal for any company looking to mitigate risks, reduce costs, and build long-term supplier relationships.