Supplier Risk Management - How to Stay Ahead of Disruptions

Strengthen your supply chain with effective supplier risk management. Learn 2025 strategies to predict, prevent, and manage supplier disruptions.

200+ buyers trust Torg for sourcing

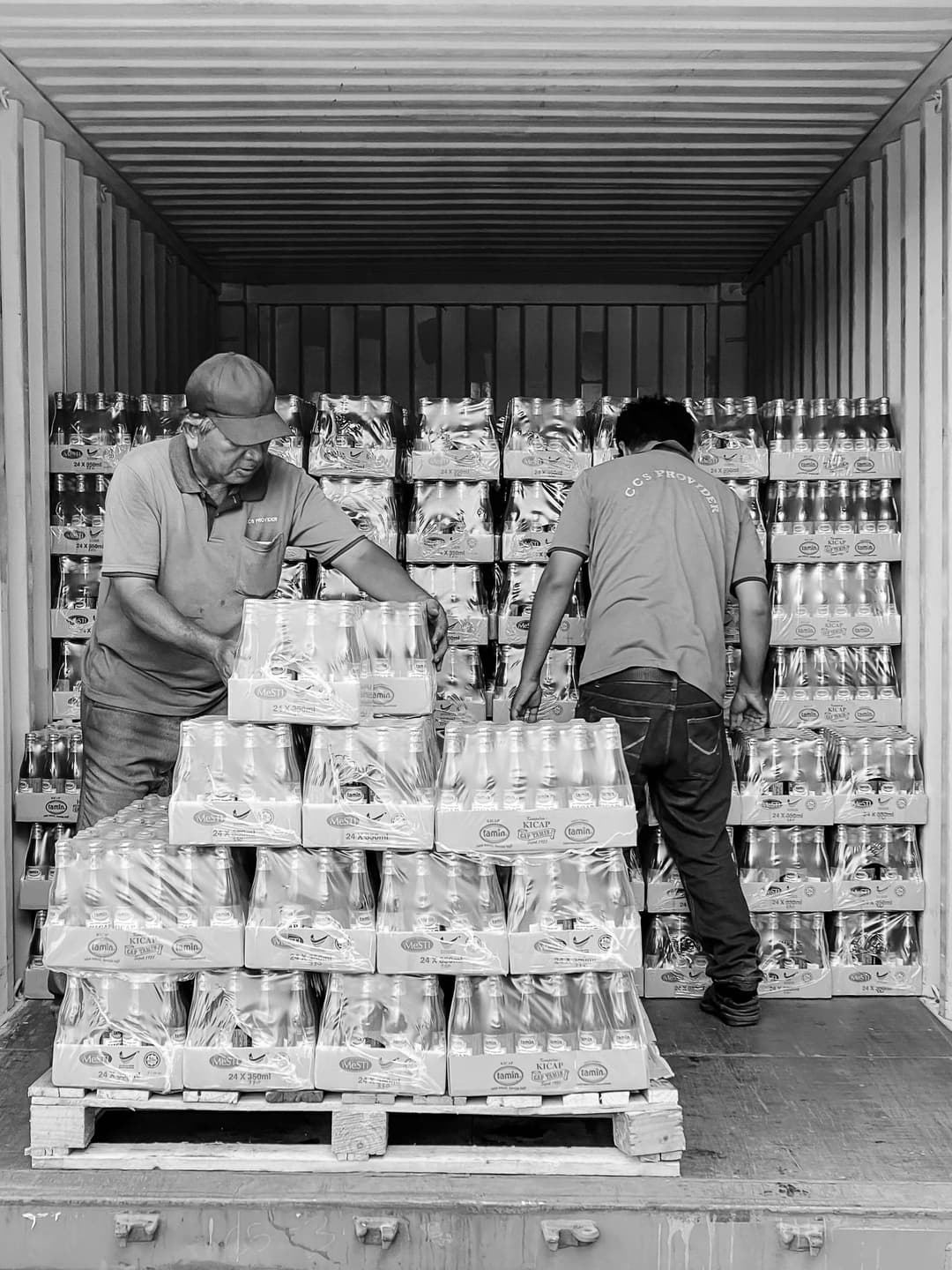

No matter what industry you're in, manufacturing, food, retail, or technology, your daily routine is based on someone, somewhere, receiving raw materials, components, or services to you within a timely manner. However, occasionally things go awry. A country where a supplier is located is flooded. A factory closes down due to non-compliance or modern slavery concerns. Or perhaps, your most important vendor is financially troubled and suddenly can't deliver on performance. That is when you realize how tenuous the network actually is.

This is where supplier risk management comes into play. In this guide, we’ll go over risk categories, frameworks, risk assessment steps, and how to actually build a supplier risk management plan that works in real life. Not theory. You’ll get to see how procurement leaders, risk analysts, and supply chain teams are proactively managing supplier risk, using better data analysis, smarter tools, and sharper judgment.

What is Supplier Risk Management?

Supplier risk management is the means by which businesses manage their supply chains from collapsing when things fail. Essentially, it's all about being aware of which suppliers are likely to fail you, why they might do so, and what to do before that really happens. Supplier risk management finds itself within the broad context of supply chain risk management, but it's more narrowly concerned with the supplier relationships that keep your business going.

It includes all of the factors like financial risk, operational risk, compliance risk, etc. Basically all of those problems that tend to snowball quietly. The concept is straightforward: remain vigilant, act early, and ensure business continuity even in times of disruption. Proactive supplier risk management is viewed as critical by many organizations, particularly those in international markets. You don't wait for a factory blaze or a change in policy to lose sleep. You plan. Because, clearly, the more intelligent you become at handling supplier risk, the more robust your entire operation is.

Why Is Supplier Risk Management Important?

You can't exactly operate a business blindfolded anymore. Every shipment, every product, every partner has some sort of risk attached to it. That's why supplier risk management in procurement is now the pillar of stable operation. It's not complicating matters but simply being prepared, being intelligent, and quite literally keeping your supply chain stable when others are panicking.

Improved Supply Chain Resilience

When you begin actively managing supplier risk, you create flexibility. Such as, if a typhoon ravages your packaging supplier or political tensions bring imports to a standstill, you already have plan B. That's what supply chain resilience actually is, which is being able to flip quickly, and not freak out. Essentially, resilience is your business continuing to move even when the world isn't.

Reduced Business Disruptions

Ever had production grind to a halt because one shipment was delayed? It's nasty. Machines idle, deadlines miss, and customers get frustrated. A robust supplier risk management program prevents that from occurring. You monitor and mitigate risks, mark areas of weakness, and ensure business continuity isn't left to chance. Somehow, having that control in the first place saves you time, money, and your sanity.

Better Cost Control

Here's the thing, crisis management is far more expensive than prevention. Rush orders, air freight, or inventory waste all add up quickly. When you have your supply chain risk managed, you spend less fixing issues and more on optimizing costs. You begin to realize how mitigation actions upfront can help safeguard your margins downstream. Easy math, but it makes all the difference.

Stronger Supplier Relationships

Suppliers are not simply vendors. They are members of your value chain. When you communicate openly and exchange performance information, you actually build trust. They get to view your standards, your consistency, and they rise to it too. By and by, that sort of procurement transparency becomes mutual supplier risk mitigation. In short, improved relationships equal fewer surprises and more aligned outcomes.

🎯 Turn supplier transparency into smarter sourcing with Torg. We connects you with 150,000+ vetted suppliers, simplifies purchasing, and helps you source with confidence. 👉 Sign up for free now!

Enhanced Compliance and ESG Performance

Brands today are often as criticized for their morals as they are for their goods. Legislation regarding modern slavery, forced labor, and damage to the planet is rigorous, and it should be. Companies that integrate supplier risk management solution get compliance requirements done quicker and neater. They're prepared for inspections, sidestep reputational damage, and remain in step with ESG issues that investors and customers are interested in.

Types of Supplier Risks

To really manage supplier risk, you have to know where the cracks usually form. Risks often overlap including financial, operational, environmental, even ethical. Here’s a quick breakdown of the big ones, along with how they actually show up in global supply chains.

Financial Risks

Firstly, when a supplier’s finances fall apart, so does your supply chain. Think of a coffee supplier in Latin America suddenly unable to pay workers because of currency instability and economic uncertainty. Orders stop. Beans don’t arrive. The financial risk spreads fast, like a ripple that hits production schedules and delivery performance. Many food brands have learned the hard way that relying on a single supplier can turn a balance sheet issue into a full-blown crisis.

Operational Risks

Even stable suppliers can face hiccups. Machinery breaks. Workers strike. A packaging plant runs out of raw materials. Supplier risk management in food industry means spoiled goods or delivery delays that affect supermarkets and restaurants almost instantly. Operational risk is the kind that doesn’t care about your deadlines and somehow, it always hits right before peak season or product launch.

Geopolitical & Regulatory Risks

When governments change rules overnight, suppliers feel it first. For example, new export limits on palm oil or dairy regulations can slow down your shipments. Asia felt it first in 2024 as beverage brands were caught off guard when customs rules flipped mid-quarter. No warning, no anything. That's what happens with geopolitical risk. It's not always on the news, but it can quietly eat away profits and jeopardize your supply chain continuity.

Environmental & Sustainability Risks

Weather patterns are unpredictable these days. A Spanish drought affects olive oil production. Excessive flooding in Southeast Asia postpones sugar shipments. All these are environmental risks and they're no longer uncommon. Food companies are also under pressure due to ESG issues, such as modern slavery, forced labor, and waste management. When supply chain sustainability slips occur, reputational harm can strike more severely than the material loss itself.

Quality Risks

Picture buying bulk spices and discovering contamination as a result of poor hygienic controls. That's a quality issue, and it can put your business operations out of business overnight. Food recalls, safety audits, customer outrage, it all boils down to one supplier taking shortcuts. Some companies now apply tougher supplier evaluation criteria to prevent this, but clearly, shortcuts still occur.

Cybersecurity & Data Risks

You wouldn't think a food firm has anything to fear from hackers, but it does. If suppliers share systems for order tracking or logistics, a single weak password can release confidential information. In 2025, Asahi—the giant behind Japan’s best-selling beer—was crippled by a ransomware attack that spread through a logistics partner, halting production at nearly all its factories. Shipments halted, computer systems crashed, and even simple orders had to be processed by pen and fax. A reminder that risk in suppliers these days goes far beyond trucks and warehouses—cyber vulnerabilities can just as readily halt physical operations.

How to Identify Supplier Risks

You must find what's broken or likely to break before you can repair anything. That's essentially what supplier risk identification is all about. It’s less about fancy tools, more about curiosity. The digging, the connecting, the asking. Those win. Here's how to assess supplier risk:

- Map out your supplier base: Don't just go to Tier 1. Drill down — second-tier, perhaps even third-tier suppliers. Latent dependencies are quietly hiding in another's spreadsheet until they detonate.

- Gather pertinent data: Financials, ESG data, or compliance documents, get it all. Examine climate change, cyber posture, and labor practices as well. That's where early warning signs of supplier risk tend to appear.

- Engage with your suppliers: Ask what's their disaster recovery plan? Do they use subcontractors? Are they sure about supplier capacity or cash flow? Those conversations get you the information no dashboard can.

- Apply external data feeds: News, credit bureaus, regulatory changes, and social media chatter, they all contribute to a clearer understanding. You'd be amazed at how quickly you can get a jump on warning signs using the proper supplier risk management tools.

- Run scenario planning: Try the "what if" game. What if a natural disaster happens? Or a regulatory ban? Or a labor strike? Practicing supply chain disruptions allows you to have a holistic view of how bad things might really get before they happen.

- Check in-house: Procurement sees one corner. Finance, another. Operations? They see the moving parts in between. Yet sometimes, it’s a single line in a buyer’s email that says more than an entire supplier audit checklist ever could.

Risk spotting isn’t some kind of fortune-telling. It's staying alert. Preparing, not guessing. One supplier, one signal, one step at a time.

Supplier Risk Assessment Framework

The framework lets you look at patterns, rather than problems. You begin to connect dots between suppliers, other risks, and what those risks might actually mean for your business. This is how the supplier risk management process generally goes:

Step 1: Risk Mapping

First, consider this step as laying all your cards on the table. List your suppliers, every single one. Big or small. Local or global. Now, flip the lens and look at each not as a partner, but as a potential point of failure. What kind of trouble could each bring? Financial collapse? Operational failures? A compliance misstep? Maybe something more critical, like a cyber breach or ESG scandal. Does your brand’s reputation take a hit? Do your lines stop running? Do the lights go out altogether?

That’s the heart of it. You’re sketching out a map of risk. Not a pretty chart, but a heat map that burns where it hurts most. It shows who’s solid and who’s sitting on thin ice. The goal of this is to see the storm before it hits, so you can brace, pivot, or walk away before the damage lands.

Step 2: Risk Scoring & Rating

Once the map's clear, you add values. Assign a supplier reliability score to each supplier. It could be 1–5, could be 1–100, depending on your setup. Bring likelihood and impact together, and create a supplier risk scorecard that displays the overall risk profile.

Here is where judgment counts. You may prioritize financial risk more, some companies emphasize supplier compliance risk or operational breakdown. You can actually segment suppliers by tiers (critical, major, or minor) and group them into risk levels like high, medium, or low. Just focus on what really matters instead of getting buried in data.

Step 3: Ongoing Risk Monitoring

Here's where a lot of businesses fall down. They leave it at scoring. But supplier risk management can't stay frozen in time. Risks evolve, suppliers move on, and new perils arrive. So, keep it fresh. Utilize supplier risk monitoring systems, dashboards, or notifications that inform you when things alter, perhaps a financial instability, a regulatory update, or an ESG breach arises.

Apparently, it's about getting ahead, maintaining competitive advantage, and not cleaning up afterwards. You continue to hone the process as new pertinent information arrives, tweaking when your risk exposure shifts.

How to Build a Supplier Risk Management Plan

So, you've done your research. You've determined the risk and constructed the structure. Now comes the moment where you actually do something about it. A good supplier risk management plan takes all that information and makes it real action — something that insulates your company's operations when things collapse. Here's how to do it.

Identify Key Suppliers

Begin with the ones that truly matter which are your lifelines. These are typically suppliers who are tied to key materials, big contracts, or one-of-a-kind tech that others can't readily substitute for. In essence, if they fail, you fail. A lot of procurement leaders refer to this as the "no-fail" list. With that list, you can then concentrate your risk management efforts where they mean the most.

Assess Risks and Impact

Then, drill deeper. For every major supplier, run your supplier risk assessment model to determine what might actually break and how bad it really will be. What if one of them doesn't deliver? How much of your manufacturing grinds to a halt? This is where exposure to risk is real, not figures, but business consequences. It's like tracking how one loose link can bring down an entire chain.

Define Risk Tolerance and Response Plans

Each firm is more or less comfortable with risk. Some risk-averse; some make aggressive bets. Decide where you're at. Once you understand your risk tolerance, frame your mitigation steps accordingly. For high-risk providers, perhaps you have alternative sourcing or backup manufacturing planned out. For moderate ones, perhaps more rigorous SLAs or additional audits will suffice. The concept is straightforward: know when to play and what "appropriate action" looks like before you need to play it.

Set Up Monitoring Tools

This is where technology earns its worth. Set up dashboards, alerts, and external data feeds that monitor supplier changes in real time. These are typically financial risk, regulatory updates, or even ESG incidents. You can't control what you can't see. So make monitoring a habit of you and your team. Integrate it with procurement risk management and operations teams to ensure everyone catches early signs of distress, not just the risk department.

Review Regularly

Everything in supply chains changes eventually. Markets change, suppliers consolidate, catastrophes occur. So you require regular reviews, perhaps quarterly, perhaps biyearly, to review your vendor risk management plan. Renew scores, revalidate dependencies, and adjust your supplier risk management strategies. That practice of ongoing improvement keeps the system up-to-date and applicable.

5 Best Strategies to Mitigate Supplier Risks

You can’t erase the cracks, yet you can build a supply chain that flexes, sharp, fast, unshaken when the ground shifts. Here are five strategies on how to reduce supply chain risk:

Dual Sourcing and Multi-Sourcing

Essentially, don't put all your eggs in one basket. Diversifying your supply with two or more suppliers ensures that if one is unable to perform, the other does. For example, a soft drink manufacturer purchasing sugar from two nations prevents complete shutdowns when one area suffers from a drought. That's real-life proactive supplier risk management.

Contractual Safeguards and SLAs

Your contract is your protection. Define SLAs clearly, set performance penalties, and add strict compliance clauses. Cover ESG breaches and outline recovery steps. Where there are no gaps, there's no guessing. It's like painting a line before it gets ugly. When a supplier is aware of the limits, both of you handle risk exposure with more confidence.

Supplier Diversification by Geography

Having all your major suppliers in one geographic location is a recipe for disaster. Political instability, natural disasters, or dockworker strikes can shut the whole thing down. Disperse your suppliers across geographies. Just as global snack food companies procure packaging from Europe as well as Southeast Asia. In case one of them is shut down, the other continues production. Easy, but effective.

Collaborative Risk Management and Supplier Development

You don't simply watch suppliers, you develop alongside them. Collaborate on audits, training, and process development. When suppliers advance their own risk consciousness and operational strength, your whole supply chain resilience is bolstered. Promote open communication and early alerts. It's not micromanaging; it's collaboration that is rewarded when the heat is on.

Building Safety Stocks or Backup Production

Sometimes you simply need a pillow. Additional inventory or a second production facility sounds expensive, but in volatile times, it's pure gold. When one of your suppliers experiences production failures or shipping delays, those safety stocks maintain your business continuity planning. It's like an umbrella, a nuisance to carry until it rains. Then you're thankful you did.

Technology in Supplier Risk Management

You simply can't reduce supplier risk nowadays without mentioning technology. Manual spreadsheets and lagging reports? They just don't work any longer. With the speed at which supply chains operate, businesses require systems that identify risks before they snowball. And that's where relevant data, automation, and AI come in.

AI in Supply Risk Management

AI is no longer this science fiction add-on but rather an integral part of the workday procedure. With advanced predictive modeling and advanced analytics, companies can now glimpse early indications like financial instability, slowing deliveries, or even subtle supplier risk patterns buried deep inside third-party networks. Some platforms even employ generative AI or knowledge graphs to discover hidden supplier connections three or four tiers down the supply chain.

It's essentially having a second pair of eyes, ones that never tire and can see between the lines. A drinks brand, for instance, could apply machine learning to notice that the credit rating of its bottle supplier is on the slide, so there's a subtle switch to a more secure standby. That's proactive risk management of suppliers. Not resting on their laurels until it all goes wrong, but noticing it from miles away.

Supplier Risk Management Software

And then there are the tools, dashboards, alarms, risk scoring engines, all aligned with procurement software. They handle supplier performance management, compliance risks, and even climate or ESG events in real time. Some build automated risk heat maps, others tap into outside databases for ongoing supplier surveillance.

It's about being able to see the entire picture at once. Think about running a thousand suppliers distributed over five continents; it's impossible without proper software. All these tools compile all that noise into one tidy view, so when financial risk or operational interruptions come along, you can respond quickly rather than react late.

Supplier Risk Management Best Practices

Building a strong supplier risk management system isn’t just about having tools. It’s about habits. The everyday stuff. The way teams think, talk, and act when risks start to show up. Here are a few practices that make the biggest difference, especially when things get unpredictable.

Regular Supplier Performance Reviews

Do not wait for the fires to ignite before examining the smoke. Establish definite review periods, perhaps quarterly, perhaps twice a year. Review delivery performance, compliance, financials, and quality measurements. Compare performance over time using supplier reliability scorecards. Such reviews ensure that minor glitches do not escalate into full supply chain disruptions.

Transparent Communication and Partnership Building

Your suppliers are not the enemy. They are your value chain. Lay it out plain. Define your goals, share challenges, then fix it together. No guessing, no walls, just teamwork aimed at keeping things steady. When communication is open, suppliers will flag issues early. Some way or another, a quick chat now saves weeks of damage control later. This is the way effective supplier relationship management is built on trust, not tension.

Early Supplier Involvement (ESI) in Product Development

Get your suppliers involved early in product design, not later. Why? Because they may spot operating risks you can't. Maybe it’s the material that’s tricky. Or the process that refuses to stretch. Bring them in early before chaos shows up at your door. Fewer surprises. Faster flow. A sturdier chain all the way down. Sometimes, it’s that simple: two minds thinking beats one that's scrambling.

Continuous Improvement Mindset

Risk management moves, so you move with it. Continuously refine it. Check your supplier risk models, don't let mistakes happen twice, update your risk mitigation plans, and train teams to identify weak signals. Being in constant improvement is how you remain flexible. When procurement leaders and key stakeholders embed this attitude into everyday work, risk awareness becomes a default, part of the company culture.

Supplier Risk Management Case Studies

Sometimes theory doesn't connect until you get to see how it plays out in life. These two cases illustrate how supplier risk management can break or make operations — and the way clever planning can convert chaos into control. Each case draws from real patterns we’ve seen across industries, grounded in solid research and proven frameworks.

Case Study 1: Supplier Disruption in the F&B Industry

A food manufacturer faced a major disruption when a key dairy supplier's facility caught fire, halting production for weeks. To manage the situation, the company quickly sourced dairy from alternative suppliers and adjusted its production to focus on non-dairy products. They also communicated openly with customers, offering temporary product substitutions.

Production was fully restored within a month, and customer satisfaction remained strong due to proactive communication and quick action. This situation emphasized the need for supplier diversification, having contingency plans, and maintaining clear communication with customers during disruptions.

Case Study 2: Stock Shortage in Retail Due to Shipping Delays

A fashion retailer encountered severe stock shortages during peak season because of shipping delays caused by port congestion. To handle the issue, they prioritized shipping high-demand items first and allowed customers to pre-order out-of-stock products. They also used air freight for key items to speed up deliveries.

While not all stock arrived on time, the retailer kept sales up with promotions and pre-orders. This experience highlighted the importance of flexible shipping strategies, stock prioritization, and clear communication to navigate unexpected supply chain issues.

Challenges in Supplier Management

Regardless of how great your supplier risk management framework is, things can still fall through the cracks. Some potential risks hide in daylight, others build quietly, layer by layer. The trick is spotting them before they hit—but that’s rarely simple. Here are a few trouble spots worth watching.

Relying on Outdated Supplier Data

Old information is like basing tomorrow's trip on last year's weather forecast. It simply doesn't cut it. When supplier information isn't updated financials, ESG concerns, or compliance risk reports, all teams are forced to respond in the dark. Most organizations hold on to static spreadsheets, and their risk analysis instantly becomes meaningless.

Lack of Contingency Planning

Tier-1 suppliers are expected to deliver every time by some firms. Big mistake. Without an effective backup or business continuity plan in place, even a minor glitch snowballs. When raw material becomes exhausted or a logistics partner fails, production freezes. Alternative sources of supply are no longer optional. It is part of effective supplier risk management.

Neglecting Second-Tier Supplier Risks

Here’s where a lot of hidden trouble lies. Most firms focus on direct suppliers and forget about the second or third tiers, where the supplier network actually stretches. That’s where you’ll often find the weak spots: sub-suppliers with financial instability or non-compliance issues. Out of sight shouldn’t mean out of mind.

Over-Dependence on Single Sourcing

At times it seems simpler to have just one reliable supplier, until there is a shutdown at that supplier. Single sourcing appears efficient but it is hazardous. Markets change, governments modify policies, or disasters occur unexpectedly. A wise procurement plan always has in the mix supplier diversification and a well-defined plan for your procurement resilience.

Trends in Supplier Risk Management

With climate events, tech shifts, and new legislation, the game is now about anticipation, not response. These are some of the largest trends that are transforming the way companies manage supplier risks these days.

ESG, Human Rights, and Social Auditing

Ethics are taken even more seriously today. Modern slavery, child labor, and forced labor are today considered significant compliance risks by companies. Procurement teams demand ESG audits, supplier certifications, and real-time monitoring for reputational harm. It's all about safeguarding credibility today.

Climate Risk and Resilience

Climate change is all grit and chaos. Floods, droughts, storms, they hit supply chains where it stings most. Now, companies are mapping supplier exposure, testing operational resilience models, and stretching their sourcing across wider ground. Basically, if your suppliers can’t handle extreme weather, your business probably can’t either.

Increased Automation and Analytics

Data is finally making its contribution. Companies are using AI, machine learning, and analytics to predict disruptions in advance. Such things as network rewiring models even model what goes down if one supplier fails. It's more intelligent, quicker supplier risk management that gets through the clutter.

Deeper Visibility via Knowledge Graphs

You can’t control what stays hidden. That’s why more companies now lean on knowledge graphs and generative AI to uncover the unseen ties linking their suppliers. These technologies identify hidden dependencies buried deep in the supplier base, revealing vulnerabilities before they become complete crises.

Board-Level and C-Suite Focus

Supplier risk is officially gone upstairs. Boards of directors now require supply chain visibility, reports, and unambiguous action plans from procurement leaders. It's no longer "a back-office problem." It's a boardroom discussion. New supply chains are delicate, and CEOs are aware that risk management is right next to financial and sourcing strategy.

Conclusion

Global supply chains are complex, vulnerable, and dynamic, so proactive is no longer a choice. It's the only way to preserve your operations, reputation, and profits. A good supplier risk management program is more than checklists. It’s a mix of sharp assessment, constant watch, and smart mitigation—driven by data, AI, and a bit of human instinct. The roadblocks? Outdated supplier info, single-source traps, and hidden layers buried deep in the network. But those aren't deal-breakers. Businesses that view supplier risk as strategy, not expense, always remain ahead. Because in the real world, your supplier network isn't merely support, it is your business.

Request a Bulk Order Quote

Simple ordering, transparent pricing, delivered straight to your door