Bullwhip Effect on Supply Chain: Causes, Impact & Solutions

Understand the bullwhip effect, why it disrupts supply chains, how it impacts costs and service, and practical strategies to reduce demand shocks.

200+ buyers trust Torg for sourcing

A few small changes doesn't really stay small in supply chains. A slight shift in buying patterns, a promotion that performs better than expected, or a delayed shipment can quietly ripple upstream and grow into something much larger. This is where many supply chains start to strain. The bullwhip effect on supply chain matters because it distorts planning, inflates costs, and weakens trust between partners.

This article is for anyone involved in getting a product from A to B in retail, manufacturing, healthcare, and consumer goods. You'll get the lowdown on how the bullwhip effect works, what causes it, and the harm it can do. Then we'll get into some practical strategies for reducing the risk of it all going wrong such as improving coordination, using forecasting to your advantage, and actually taking control of your supply chain optimization.

What Is Bullwhip Effect on Supply Chain?

The Bullwhip Effect on supply chain shows up when demand signals get distorted as they travel upstream. A small change at checkout can look bigger to distributors, and even bigger to manufacturers. Orders start to reflect fear, buffers, and assumptions, not real demand.

Over time, this demand amplification creates supply chain variability that’s hard to manage. Inventory builds up in the wrong places. Production plans keep changing. Logistics teams scramble. One month feels like growth, the next feels like cleanup, with excess inventory or sudden stockouts.

Understanding what are the effects of bullwhip effect on supply chain helps leaders spot why plans keep breaking, costs keep rising, and supply chain efficiency slips, even when customer demand hasn’t changed much at all.

How the Bullwhip Effect Works

This process explains why supply chains swing so sharply. Each stage reacts to partial signals, adds protection, and passes amplified demand forward, creating instability that feels sudden but builds quietly.

Where the Signal First Breaks

Retail decisions often start the chain reaction. Small fluctuations in demand trigger forecast adjustments, safety stock changes, and revised replenishment strategies. Those signals already carry assumptions. By the time orders move upstream, they reflect expectations, not real buying behavior, setting demand amplification in motion early across retail supply networks globally.

How Orders Get Distorted Upstream

Upstream partners respond to orders, not shoppers. Wholesalers and manufacturers rely on historical demand forecasting, limited point of sale data, and fixed planning cycles. When lead times feel uncertain, teams pad their orders. Batch sizes grow to “play it safe,” while pricing strategies pull demand forward or push it back. With every handoff, those choices compound, quietly increasing supply chain variability across already complex global networks.

Why the Impact Keeps Growing

Over time, small distortions compound. Inventory distortion appears, excess inventory builds in some nodes, while stockouts hit others. Production schedules shift, capacity utilization suffers, and logistics inefficiency grows. Without strong information sharing in supply chain operations, coordination weakens and supply chain responsiveness steadily declines, raising supply chain risk significantly overall.

The Bullwhip Effect Example

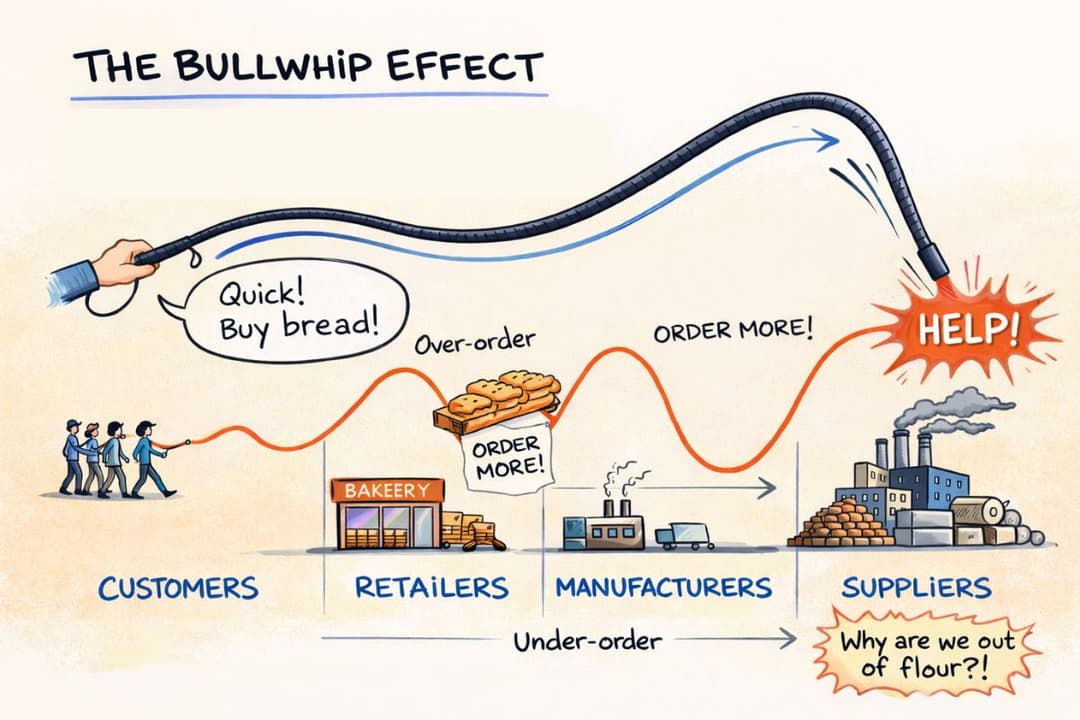

The illustration shows how a small increase in customer demand for bread can create increasingly large fluctuations as it moves up the supply chain.

- Customers: A few customers panic and buy extra bread. The actual demand change is small.

- Retailers (Bakeries): Retailers see shelves empty faster than usual and over-order to avoid running out. Their orders are larger than the real increase in demand.

- Manufacturers: Seeing inflated orders from retailers, manufacturers assume demand is booming and ramp up production even more.

- Suppliers: Suppliers receive the largest, most distorted signals and struggle to keep up, leading to shortages, excess costs, or later oversupply.

The wavy line represents how order variability grows at each stage, just like a whip, where a small movement at the handle creates a large snap at the tip.

This amplification causes overstocking, shortages, production stress, and higher costs, even though the original demand change was minor.

6 Causes of the Bullwhip Effect in Supply Chain

The bullwhip effect rarely comes from one bad decision. It builds through everyday habits, planning shortcuts, and protective behavior. These six bullwhip effect causes show how small, reasonable actions quietly compound into supply chain variability over time.

Demand Forecasting Errors

Forecasts often rely on historical averages, limited windows, or assumptions that no longer fit reality. When demand forecasting errors enter early, they multiply upstream. Without strong consumer behavior analysis and timely point of sale data, normal fluctuations in demand get mistaken for lasting shifts, distorting supply chain planning.

Order Batching

Order batching looks efficient, yet it masks true demand patterns. Large, infrequent orders create artificial spikes that suppliers interpret as growth. This disrupts capacity utilization, triggers production inefficiency, and drives inventory distortion. Over time, batching increases supply chain inefficiency and raises inventory holding costs across networks.

Price Fluctuations and Promotions

Temporary pricing strategies pull demand forward. Customers buy early, stock up, and then disappear. That behavior fuels demand amplification, followed by sudden drops. Planners react to the surge, not the reason behind it, leading to excess inventory, stockouts later, and unstable inventory management across the supply chain.

Lead Time Variability

When lead times feel unreliable, companies protect themselves with buffers. Orders grow larger, safety stock expands, and replenishment strategies lose precision. These defensive moves stack up across tiers, increasing supply chain risk and making inventory management harder to stabilize, even when actual demand remains relatively steady.

Lack of Information Sharing

Without information sharing in supply chain networks, partners plan in isolation. Orders replace insight. Inventory levels, production plans, and real demand stay hidden. This weakens collaborative planning, breaks supply chain coordination, and amplifies uncertainty, directly worsening the effects on supply chain performance.

Behavioral Factors

Human judgment shapes decisions more than data admits. Fear of shortages, pressure to hit targets, and short-term incentives push teams to overreact. “Just in case” ordering feels safe locally, yet these behaviors quietly fuel supply chain variability and undermine long-term supply chain efficiency and trust.

The Impact of Bullwhip Effect on Supply Chain Performance

Performance issues rarely arrive all at once. They build quietly as distorted demand moves upstream. Over time, the bullwhip effect reshapes how supply chains serve customers, run operations, and respond to risk, often without teams noticing until the pressure becomes hard to ignore.

Inventory Imbalances

Inventory rarely lands where it’s needed most. The bullwhip effect impact on supply chain often shows up as excess inventory in one node and stockouts in another. These swings inflate inventory holding costs, lock up cash, and strain inventory management teams trying to rebalance supply without reliable demand signals.

Rising Supply Chain Costs

Costs rise in subtle and obvious ways. Emergency freight, rushed production, overtime labor, and temporary storage all add up. The impact of bullwhip effect on supply chain performance becomes clear when margins shrink, even though overall demand hasn’t changed, exposing hidden supply chain inefficiency and weak cost control.

Lower Customer Service Levels

Service problems rarely start at the customer desk. They begin upstream when inventory signals wobble. Missed delivery windows, partial shipments, and sudden substitutions chip away at reliability. Over time, customer service level drops, trust thins out, and buyers start padding orders themselves, quietly feeding instability back into the supply chain loop.

Production and Capacity Challenges

Production pain shows up in waves. Plants rush during spikes, then sit idle when orders fade. This stop start pattern hurts capacity utilization, inflates unit costs, and complicates labor planning. Instead of steady improvement, teams chase volume swings, reschedule shifts, and delay investments that would otherwise support stable, predictable output.

Reduced Resilience

Resilience erodes slowly, then all at once. When teams spend months reacting to noise, buffers replace planning. Each disruption feels manageable, until several hit together. At that point, supply chain risk rises, recovery slows, and confidence drops that the network can absorb shocks or adapt to longer term change cycles.

Real-World Examples of the Bullwhip Effect

Supply chain reality brings the bullwhip effect to the surface way before theory can. These bullwhip effect examples give us a glimpse into how everyday choices, the push of incentives, and uncertainty can take a tiny change in demand and suddenly turn it into a huge operational headache across all kinds of industries.

Bullwhip Effect in Retail

In retail, promotions can quietly distort signals. Walmart and Target often see demand spikes during discounts, so stores reorder aggressively. Suppliers read those orders as lasting growth. When promotions end, volumes fall, leaving excess inventory upstream, stressed replenishment strategies, and strained relationships that take time, patience, and coordination to reset across global retail networks with seasonal cycles repeating each year.

Bullwhip Effect in Manufacturing

In manufacturing, the bullwhip effect often starts at dealerships. Automakers like Toyota and Ford see dealers place larger orders to secure allocation. Those signals push suppliers to ramp production. When real demand settles, factories face capacity whiplash, idle lines, and sudden cost pressure that lingers well beyond the sales cycle for upstream partners and logistics teams across tiers globally.

Bullwhip Effect in Pharmaceutical and Healthcare

In healthcare, fear of shortages shapes ordering habits. Hospitals react early, so companies like Pfizer and Johnson & Johnson see sudden volume spikes. Distributors follow suit. When demand settles, inventory lingers, cash locks up, and inventory management grows harder under regulation, audits, and strict service expectations across regional care networks.

Bullwhip Effect During COVID-19

The COVID-19 supply chain impact definitely turned uncertainty into action. Panic buying pushed brands like 3M, Procter & Gamble, and Unilever into overdrive. Orders surged fast and visibility easily vanished. Later, the demand slowed down, but the excess inventory filled warehouses, revealing how fear, speed, and weak coordination can overwhelm even global supply chains during prolonged crisis conditions worldwide.

10 Best Strategies to Reduce the Bullwhip Effect

Reducing the bullwhip effect is slow work, not instant. With clearer signals, shared data, and consistent habits of bullwhip effect solutions, teams stabilize demand, cut risk, and protect long-term supply chain performance across industries.

1. Improve Demand Forecasting

Better forecasting starts with accepting uncertainty. Shorter planning cycles allow teams to correct courses faster. Using point of sale data and consumer behavior analysis reduces demand forecasting errors, limits overreaction to fluctuations in demand, and supports more stable inventory management strategies across changing market conditions and seasonal demand patterns.

2. Share Information Across Partners

When partners operate in silos, assumptions replace facts. Strong information sharing in supply chain networks improves trust and alignment. Visibility into inventory levels, demand shifts, and production plans reduces defensive ordering, improves supply chain coordination, and lowers supply chain variability caused by delayed or incomplete signals moving upstream.

3. Adopt Vendor Managed Inventory

Vendor managed inventory shifts replenishment decisions closer to actual consumption. Suppliers restock based on usage, not inflated orders. This smooths replenishment strategies, reduces excess inventory, improves supply chain responsiveness, and lowers inventory holding costs caused by panic buying and safety stock inflation downstream.

4. Reduce Order Batching

Order batching often looks efficient, yet it distorts demand. Large, infrequent orders exaggerate volume swings and confuse suppliers. Smaller, regular orders stabilize demand signals, reduce logistics inefficiency, improve capacity utilization, and help production teams plan more predictably without reacting to artificial spikes.

5. Stabilize Pricing Strategies

Frequent promotions send mixed messages. Customers stock up early, then disappear. By stabilizing pricing strategies, companies reduce demand amplification, support more accurate demand forecasting, and prevent inventory distortion that leads to stockouts followed by excess inventory across multiple supply chain tiers.

6. Shorten and Stabilize Lead Times

Lead times shape behavior more than forecasts do. When delivery dates feel uncertain, teams protect themselves with padding and buffers. By shortening processes and making timelines reliable, ordering becomes calmer. Variability drops, just-in-time inventory works better, supply chain risk falls, and emergency freight fades, allowing supply chain efficiency to improve through steadier replenishment decisions across modern networks today.

7. Align Incentives

People follow what they are rewarded for. If bonuses favor volume, orders inflate quickly. Shifting incentives toward service reliability, cost discipline, and efficiency changes daily choices. Teams pause before overordering, balance customer service level with inventory health, and support supply chain optimization that values steady performance over short-term wins across departments, partners, and planning cycles without added friction or noise.

8. Strengthen Collaborative Planning

Planning improves when partners stop guessing and start talking. Collaborative planning brings retailers, manufacturers, and suppliers into the same conversation because shared assumptions replace defensive ordering. As visibility improves, supply chain coordination strengthens, production inefficiency fades, and trust grows. That trust matters, because calmer planning reduces overreaction when demand shifts unexpectedly and keeps execution steady across volatile periods for everyone involved.

9. Optimize Replenishment Strategies

Replenishment becomes smoother when orders reflect what customers actually use. Optimized replenishment strategies respond to real consumption patterns, not anxious forecasts. As signals stabilize, stockouts decline, excess inventory shrinks, and inventory management improves. Predictable ordering also steadies supply chain costs, supports better planning, and frees teams from constant firefighting across stores, warehouses, and production lines during uncertain demand cycles periods.

10. Focus on Total Cost of Ownership

Unit price rarely tells the full story. Total cost of ownership forces broader thinking across inventory, transport, service failures, and disruption risk. This lens helps leaders avoid false savings, compare trade-offs honestly, and make procurement decisions that protect margins while supporting sustainable supply chain resilience long after contracts are signed and unexpected shocks test assumptions repeatedly across global markets.

Bullwhip Effect vs. Forrester Effect

These two terms are often used interchangeably, yet they don’t mean the same thing. The Forrester Effect is the original systems concept explaining how delays and feedback loops create oscillations. The bullwhip effect is its real-world expression inside supply chains, where ordering behavior amplifies demand as it moves upstream.

Forrester Effect

The Forrester Effect was introduced by Jay W. Forrester in 1961 in his groundbreaking book Industrial Dynamics. It explains demand amplification using system dynamics theory, focusing on:

- Information delays

- Feedback loops

- Forecasting and decision-making behavior

Forrester demonstrated that even when customer demand is stable, poor information flow and delayed responses within a supply chain can create instability, inventory oscillations, and production inefficiencies. The Forrester Effect is primarily discussed in academic and theoretical research.

What Is the Bullwhip Effect?

The Bullwhip Effect is the modern, widely used term that gained popularity in the 1990s through real-world supply chain studies. The name comes from the visual analogy of a whip, where small movements at the handle lead to large swings at the tip.

In supply chains, the Bullwhip Effect highlights practical and operational problems, such as:

- Excess inventory

- Stockouts

- Inaccurate demand forecasts

- Increased operating and logistics costs

This term is commonly used in operations management, logistics, and business strategy discussions.

Key Differences Between Bullwhip Effect and Forrester Effect

Aspect | Forrester Effect | Bullwhip Effect |

|---|---|---|

Origin | Jay W. Forrester (1961) | Popularized in the 1990s |

Focus | Feedback loops and delays | Order amplification |

Scope | Any complex system | Demand and inventory flows |

Practical Impact | Conceptual insight | Inventory distortion and cost |

Usage | Academic and modeling | Operations and planning |

Bullwhip Effect vs. Demand Variability

These two ideas often get tangled, yet they describe very different issues. Demand variability starts with customers. The bullwhip effect begins after that, inside the supply chain. One reflects reality. The other reflects how teams react, interpret, and protect themselves when signals move upstream.

Demand Variability

Demand variability refers to the natural fluctuations in customer demand over time. These variations can occur due to:

- Seasonal patterns

- Changing customer preferences

- Market trends

- Economic conditions

- Promotions or product life cycles

Demand variability exists at the end-customer level and reflects actual changes in market demand. It is a normal and unavoidable part of doing business and does not necessarily indicate inefficiency within the supply chain.

The Bullwhip Effect

The Bullwhip Effect occurs when demand variability is amplified as it moves upstream in the supply chain. Even when customer demand changes slightly, suppliers and manufacturers may experience much larger swings in orders, inventory, and production levels.

This amplification is typically caused by:

- Inaccurate demand forecasting

- Order batching

- Price fluctuations and promotions

- Long lead times

- Lack of information sharing

Unlike demand variability, the Bullwhip Effect is man-made and results from poor coordination and decision-making within the supply chain.

Key Differences Between Bullwhip Effect and Demand Variability

Aspect | Demand Variability | Bullwhip Effect |

|---|---|---|

Source | Customer behavior | Supply chain decisions |

Nature | Natural and expected | Artificial and amplified |

Visibility | Seen at point of sale | Grows upstream |

Impact | Manageable with planning | Causes instability |

Solution | Better forecasting | Better coordination |

Conclusion

Most supply chains don’t fail overnight but still, small decisions stack up, signals blur, and suddenly teams are reacting instead of planning. That is how the bullwhip effect quietly takes hold, driving excess inventory, stockouts, and rising logistics pressure without anyone intending it.

When demand forecasts are grounded in real data, information flows between partners, and inventory decisions reflect actual usage, the noise fades. As teams stop operating in silos and start aligning, supply chain performance steadies and becomes far more predictable.

Supply chains today don’t have much margin for error. Supply chain disruptions linger, costs stay high, and expectations keep rising. When the bullwhip effect goes unchecked, pressure builds fast. But when it’s reduced, operations settle, service becomes reliable, and teams finally gain the breathing room to plan forward instead of constantly scrambling.

Request a Bulk Order Quote

Simple ordering, transparent pricing, delivered straight to your door