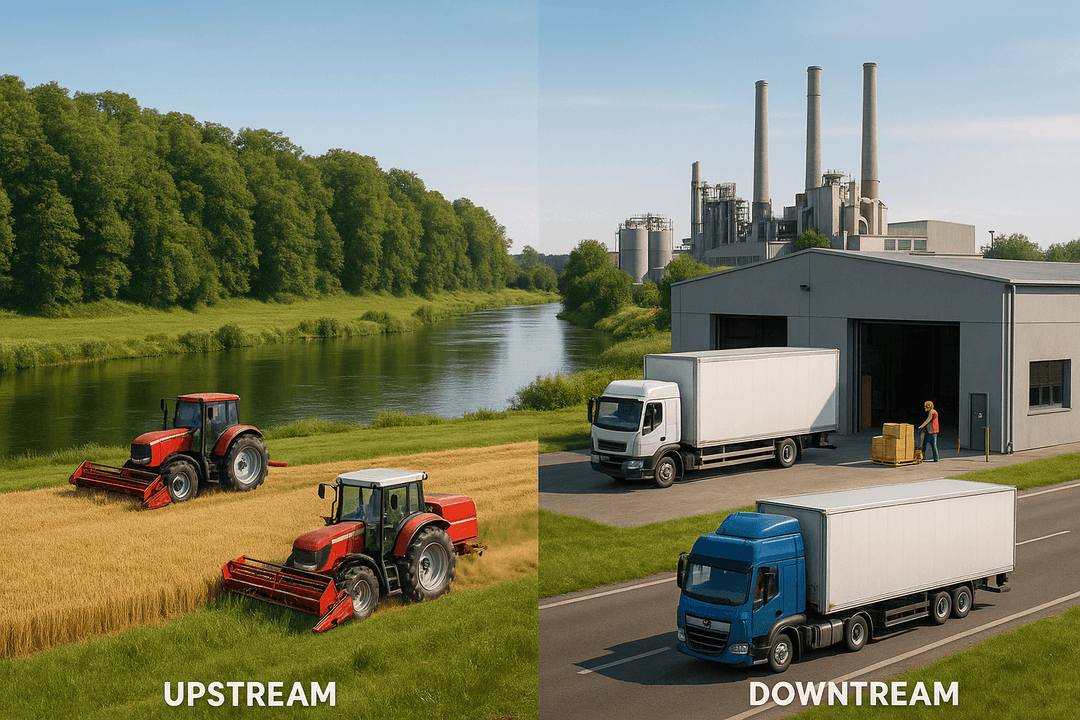

Upstream vs. Downstream in Supply Chain: What to Know

Explore the key differences between upstream vs. downstream supply chain in our complete guide. Enhance your understanding and optimize your strategy today!

200+ buyers trust Torg for sourcing

Supply chains are no longer behind-the-scenes operations—they’re strategic engines that drive growth, resilience, and customer satisfaction. To truly optimize your operations, you need to understand the flow that powers it all: upstream and downstream. Whether you're overseeing procurement, managing logistics, or refining end-to-end workflows, grasping the upstream vs. downstream dynamic is key to making smarter, faster, and more profitable decisions. In this article, we’ll break down what you need to know, why it matters, and how to apply it to your supply chain strategy.

What is the Upstream Supply Chain?

Upstream supply chain refers to all the activities and processes that happen before a product is manufactured. It includes sourcing raw materials, managing suppliers, and handling the logistics that bring those materials to the production stage. In simple terms, it’s everything involved in getting the right inputs in place to start making a product.

How it works:

- Supplier Relationships – Businesses identify and work with suppliers who provide raw materials or components.

- Procurement – Materials are purchased based on demand forecasts or production schedules.

- Inbound Logistics – The raw materials are transported to the manufacturer or assembly facility.

- Inventory Management – Materials are stored and prepared for use in the production process.

Example:

Consider a company that produces bottled fruit juice. The upstream supply chain might include:

- Fruit farms that grow oranges, apples, or berries

- Suppliers that provide sugar, flavorings, and preservatives

- Packaging manufacturers that supply bottles and caps

- Transportation providers that deliver all materials to the processing facility

These upstream activities are essential to ensure the juice company has fresh, quality ingredients ready for production. Delays or shortages at this stage can disrupt the entire supply chain.

Key Characteristics of Upstream Operations

- Procurement-centric: Strong emphasis on manufacturers procuring raw materials and parts cost-effectively.

- Supplier relationship: Developing close, diversified relationships with reliable suppliers to have a stable supply.

- Forecasting and planning: Aligning procurement with the production schedule and forecast customer demand.

- Inventory and cost control: Efficiently managing inventory levels in balance while coordinating raw material prices and availability.

- Risk management: Preparing for interruptions such as natural disasters, economic changes, or sourcing problems.

What Is the Downstream Supply Chain?

The downstream supply chain refers to all the activities and processes that take place after a product is manufactured. It includes distribution, warehousing, sales, and delivery to the end customer. In simple terms, it’s everything involved in getting the finished product from the factory to the consumer’s hands.

How it works:

- Distribution Channels – Businesses partner with wholesalers, retailers, or e-commerce platforms to reach customers.

- Warehousing & Inventory – Finished products are stored and managed before being shipped to sales outlets or directly to consumers.

- Transportation & Logistics – Goods are moved from warehouses to retailers, distributors, or customers via various transportation methods.

- Sales & Customer Service – Products are sold through different channels, and post-sale support is provided to ensure customer satisfaction.

Example:

Consider a company that produces bottled fruit juice. The downstream supply chain might include:

- Warehouses that store the bottled juice after production

- Distributors that transport products to grocery stores and supermarkets

- Retailers that stock and sell the juice to consumers

- Online platforms that offer the juice for direct-to-consumer shipping

All of these steps ensure that the final product reaches the market efficiently, on time, and in good condition. A strong downstream strategy helps the company grow sales, build brand loyalty, and maintain customer satisfaction.

Key Characteristics of Downstream Operations

- Customer-centric: Focuses on delivery times, service, and seamless customer transactions.

- Logistics-driven: Dependent on intelligent inventory storage, warehousing, and distribution networks.

- Demand-based decisions: From promotions to restocking, it's based on real-time customer information.

- Quality and consistency: Products should reach the site, at time, and also match standards of quality.

- Marketing synergy: Promotions and marketing strategy feed immediately to inventory and sales plan.

How Do Upstream and Downstream Supply Chains Work Together?

Upstream and downstream supply chain functions aren't silos, that are well connected. What happens at sourcing impacts just how well a product moves to the customer. If upstream supply chain activities such as sourcing of raw materials or managing supplier delays do not go right, downstream processes suffer thereby causing missed production schedules, delayed shipments, and frustrated customers.

Supply chain managers have to keep both ends in sync. That means aligning procurement, inventory, production, and delivery into one smooth operation. When upstream and downstream are coordinated, you avoid supply chain inefficiencies, improve operational efficiency, and create a more reliable supply from start to finish.

In short, upstream sets the tone, downstream fulfills the promise. Together, you have fewer delays, more effective service, and more resilient overall supply chain performance.

Understanding upstream and downstream dynamics is key to smarter sourcing. With Torg, find suppliers that fit seamlessly into your supply chain, from raw materials to retail-ready goods. Start streamlining your operations and boost efficiency where it counts. Sign up today to discover trusted partners.

Key Differences Between Upstream and Downstream Supply Chain

Understanding where upstream and downstream supply differ can be the key for businesses to see where they are strong and where they may break. Both focus on risk, timing, and cost, but they deal with entirely different priorities and players.

Operational Focus

Upstream supply chain operations focus on sourcing raw materials, procurement, and supplier coordination to ensure production runs smoothly. The goal is to secure reliable inputs at the right time and cost.

In contrast, the downstream supply chain emphasizes product distribution, order fulfillment, and customer delivery. It’s about moving finished goods efficiently through channels to meet customer demand and maximize satisfaction.

Stakeholder Relationships

In the upstream supply chain, relationships are built primarily with suppliers, manufacturers, and logistics providers who deliver raw materials or components. Success depends on strong supplier networks and clear communication.

On the downstream side, relationships are focused on distributors, retailers, e-commerce platforms, and end customers. Here, collaboration ensures smooth delivery, optimal shelf availability, and positive customer experiences.

Risk Management Approaches

Upstream supply chain risk management focuses on supplier reliability, material shortages, geopolitical issues, and cost volatility. Businesses develop diversified supplier bases and contingency sourcing plans.

Downstream risk management deals with demand fluctuations, delivery disruptions, inventory imbalances, and customer satisfaction risks. Companies use real-time data and agile logistics to stay responsive and minimize impact.

Midstream Supply Chain (The Bridge Between Upstream and Downstream)

The midstream supply chain is where raw materials become real products. It is positioned between sourcing and delivery and tends to be overlooked. Yet, this is where the actual transformation occurs. It encompasses the production process, inventory management, and synchronizing production schedules with demand.

This phase is very important in maintaining the smooth flow of the whole supply chain. If your factory is not able to process materials into finished products well, it does not matter how excellent your delivery teams or suppliers are.

When you get your midstream operations smooth (tight inventory control, precise forecasting, and consistent flow in production) you prevent bottlenecks, eliminate waste, and maintain your downstream supply. Simply put, the midstream is what keeps the transition between upstream and downstream clean, quick, and inexpensive.

Benefits of Optimized Upstream and Downstream Management

When both ends of the supply chain operate efficiently, everything in between gains. From cost-optimization to more satisfied customers, coordination between upstream and downstream supply chain functions is the key component to remaining competitive in any sector.

Cost Reduction Opportunities

Strong upstream supply chain management lowers raw material costs through better deals, fewer delays, and smarter supplier management. At the same time, efficient downstream supply chain encompasses cutting expenses by reducing overstock, streamlining deliveries, and tightening up inventory storage. Together, they drive real cost savings across the value chain and improve margins.

Enhanced Customer Experience

Quick delivery, correct orders, and easy returns, all these are the result of a well-organized downstream supply chain. When there is forecasting demand fulfillment and timely delivery for finished products, customer satisfaction increases. That smooth process makes your brand stronger and returning customers abound.

Competitive Advantages

Nailing upstream operations and downstream activity alike gives a firm a serious advantage. Reliable supply and consistent delivery prevent disruptions, fulfill quality standards, and foster trust. That advantage translates to more sales, improved retention, and increased market strength.

Upstream Supply Chain Challenges and Solutions

The upstream supply chain faces challenges like supplier disruptions, raw material shortages, and cost volatility. Understanding these issues—and how to solve them—is key to maintaining a stable, efficient production flow.

Unstable Raw Material Prices

Raw material prices such as metals, grains, or chemicals may go haywire based on happenings in the world, climatic conditions, or market fluctuations. Such volatility makes it difficult for supply chain managers to budget or secure long-term prices, squeezing margins and production stability.

Solution: Foster good relationships with suppliers, negotiate with suppliers about general contractual terms that allow for flexibility, and employ price forecasting software to anticipate market movements.

Supplier Reliability

A single delayed shipment or skipped quality check by a supplier can set the production process back. This is particularly dangerous when using foreign upstream suppliers, where extended lead times and little control can exacerbate exposure.

Solution: Use more than one supplier, perform frequent supplier audits, and invest in improved supplier management software to maintain performance.

Disruptions from Natural Disasters or Political Events

Earthquakes, floods, or trade embargos can halt the movement of raw materials overnight. If your firm relies on a single region or supplier, such risks are compounded, transmitting their effects downstream to the entire supply chain.

Solution: Diversify sources across regions, stockpile inventory storage buffers, and monitor global risks as part of your upstream supply chain management strategy.

Downstream Supply Chain Challenges and Solutions

The downstream supply chain encounters challenges such as demand variability, delivery delays, and inventory mismanagement. Addressing these issues ensures timely distribution, improved customer satisfaction, and a more resilient supply chain.

Transportation and Logistics Delays

Shipping carriers fall behind deadlines. Customs are slow. Fuel prices increase. Any disruption in the distribution chain results in late delivery, dissatisfied customers, and lost sales, particularly during peak seasons.

Solution: Implement automated logistics tracking, engage in well-established carrier partnerships, and have backup transport arrangements in place to enhance downstream supply reliability.

Poor Demand Forecasting

Guessing wrong on customer demand can leave you with shelves full of unwanted products or none at all when orders spike. Either way, it's bad for business and hurts customer satisfaction.

Solution: Use real-time data and sales trends to improve demand forecasting. Align inventory management and production schedules with marketing and seasonal patterns.

Lack of Coordination Across Downstream Functions

When downstream supply chain operations (like returns, packaging, or customer service) don’t talk to each other, mistakes happen. Delays, miscommunications, or missed deliveries damage the brand and cost money.

Solution: Connect your systems and teams. Use centralized platforms to align downstream activities and track everything from order placement to final delivery.

Future Trends and Technologies in Supply Chain Management

Supply chains are no longer governed by outmoded rules. From the way that we procure raw materials to the way that we transport to the retail outlets, the whole supply chain is being redefined. Technology, ethics, and worldwide risk are reinventing the playbook and supply chain managers must stay along or fall behind.

Digital Transformation Impact

Machine learning and AI are being utilized to predict demand more accurately, control inventory levels in real-time, and identify supply chain inefficiencies early. These technologies are assisting businesses in acting rapidly to customer demand while minimizing production slowdowns and waste.

Blockchain is also on the rise, particularly for industries that require transparency throughout the entire supply chain, such as pharma, food, and fashion. It assists in authenticating transactions, tracing sourcing of high-quality materials, and adhering to stringent standards of quality. Digital solutions such as these are setting new standards throughout both upstream and downstream operations.

Environmental and Ethical Considerations

Supply chains are no longer being measured by cost and speed alone. Stakeholders (ranging from regulators through to customers) are asking questions about how things are made, where materials originate, and how waste is managed.

Both upstream supply chain management now involves screening good suppliers who comply with environmental legislation and fair labor standards. On the downstream side of supply chain, brands are reducing emissions, redesigning packaging, and providing more sustainable delivery methods.

This shift is no longer a bonus; it's a requirement. ESG is no longer a dialogue in boardrooms but the future direction for managing long-term value upstream and downstream within your supply chains.

Emerging Business Models

New thinking creates new forms of building and flexibility in supplying.

- Circular supply chains close the reuse loop, reduce dependency on multiple suppliers, and waste goes down.

- On-demand manufacturing maintains thin inventory storage, reduces overproduction, and enhances responsiveness to shifting customer orders.

- Decentralized manufacturing distributes the production process across geographies. In that manner, significant that one plant can close down, another will continue to keep things going without impeding operations further downstream.

These approaches are assisting companies in creating more agile, cost-efficient, and sustainable supply chains, ones that are capable of withstanding actual-world variability without sacrificing competitiveness.

Conclusion

If you're concentrating on only one side of the supply chain, you're leaving money on the table. Each step, from raw material sourcing to delivering finished goods, must be in sync. When upstream and downstream supply chain processes are synchronized, you minimize production delays, enhance delivery timelines, and fulfill customer expectations more reliably.

Strong supplier relationships, better inventory management, and the right tech tools aren’t extras, they’re essential. Whether you’re managing upstream supply or refining your downstream strategy, the goal is the same: a reliable, flexible, and high-performing supply chain that supports long-term business success.

Request a Bulk Order Quote

Simple ordering, transparent pricing, delivered straight to your door