How to Write a Material Purchase Specification (with Sample)

Discover how to write a material purchase specification to ensure clarity, reduce sourcing errors, and streamline your procurement process.

200+ buyers trust Torg for sourcing

When you're in charge with purchasing material—be it for construction, production, or developing a new product—certain specifications can prevent a great deal of pain. A sound material purchase spec is like having a precise set of directions. It keeps both the buyer and supplier on track, prevents unnecessary and expensive missteps, and ensures that expectations on both sides meet the eventual delivery.

If you're in engineering, construction, procurement, or even operating a business that's growing, knowing how to produce this document can be the key. In this guide, we'll take you through how to create a good, effective material purchase specification step by step. You'll know what to include, key concepts, how to organize it, pitfalls to avoid, and why this process is more important than most people think.

What is a Material Purchase Specification?

A Material Purchase Specification is a detailed document that tells suppliers exactly what a company wants when buying a material or product. Think of it as a shopping list with very specific instructions. It includes all the important details a supplier needs to deliver the right item, such as:

- Type of material (e.g. stainless steel, organic cotton, high-protein soy)

- Quality standards (e.g. food-grade, ISO-certified, GMO-free)

- Size, weight, or measurements

- Packaging requirements

- Labeling instructions

- Delivery timelines

- Compliance with regulations (e.g. EU food safety rules, REACH, etc.)

The goal of a material purchase specification is to avoid misunderstandings between the buyer and the supplier. It ensures that everyone is on the same page about what’s being ordered, what quality is expected, and how it should be delivered.

In short, it helps procurement teams make sure they're getting the right material, from the right source, at the right quality—and keeps suppliers accountable.

Key Components of a Material Purchase Specification

A material purchase specification must be more than a product name with a detailed description. Whether you're procuring materials for a single project or a continuous production cycle, the information in this document can make or break your outcome. Here's what to put in to ensure your output specifications stand up to the process.

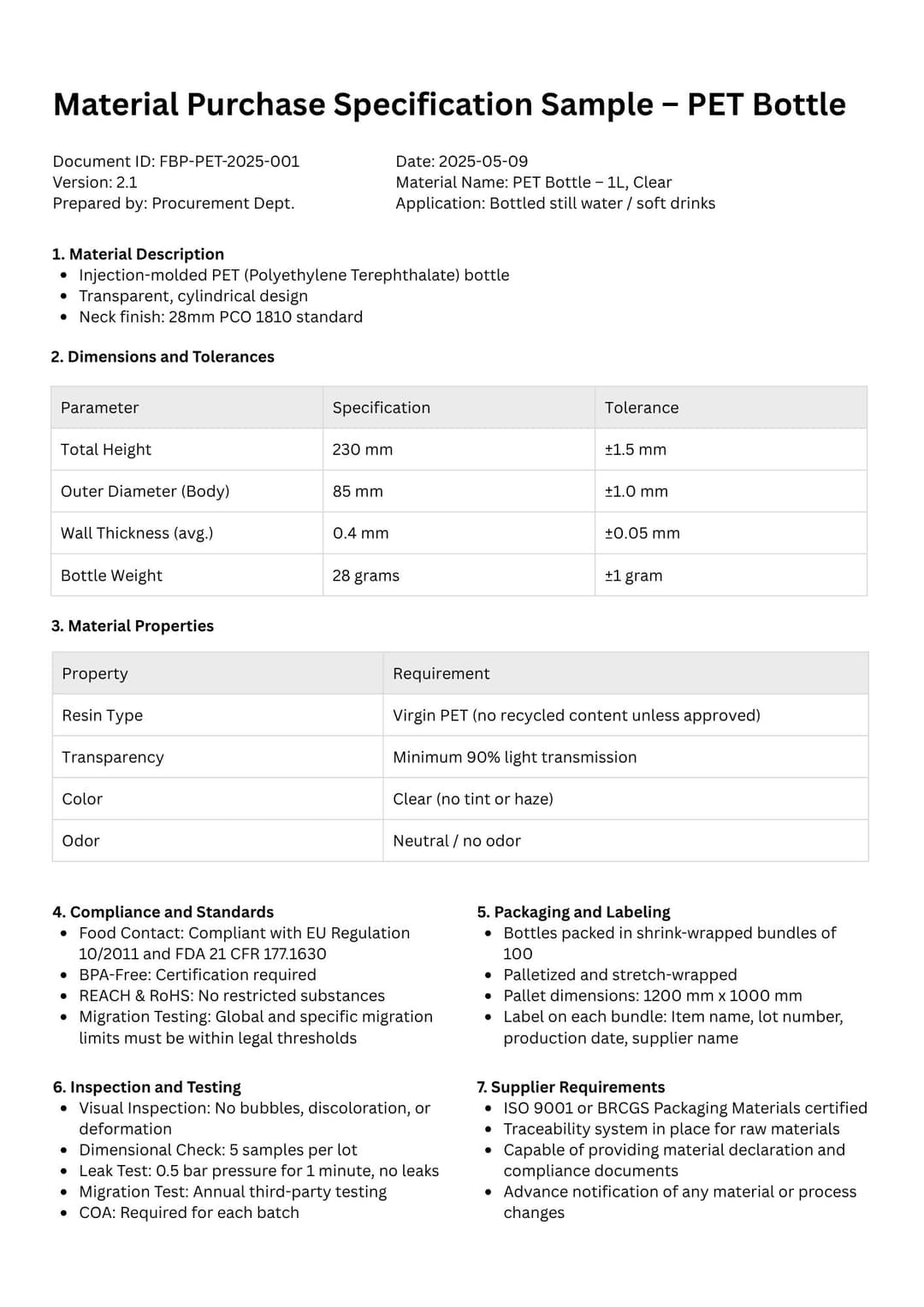

Material Type and Grade

Be precise in what you are ordering. "Plastic" or "metal" is not sufficient. Do you want aluminum alloy 6061, HDPE food-grade, or medical-grade silicone? Use trade names where possible and always specify the proper manufacturer codes or designations. This minimizes confusion, particularly if you are carrying with several suppliers from different regions. A good specification just makes sense because it makes everyone talk the same language.

Physical and Chemical Properties

This part is about what the material can do. Does it have to withstand heat, pressure, or corrosion? Must it possess high tensile strength or low density? These technical specification details must be aligned with the material's purpose and performance requirements. For instance, if the material will be subjected to aggressive chemicals, enumerate the chemical resistance properties needed. These properties are essential when you're designing around specific processes or stringent safety requirements.

Dimensions and Tolerances

Whether you're ordering sheet metal, tubing, or molded plastic components, you must specify the exact sizes such as thickness, length, width, and diameter. Equally important are the tolerances such as how much deviation is allowed in each measurement. If a component is even slightly too large or too small, it may not fit or work correctly in your production line. This part being incorrect can cause delays or quality failures.

Compliance and Certification Requirements

If you are in such sectors as electronics, building, or pharmaceuticals, most often there would be compliance norms to be met. Mention these as certifications such as REACH, RoHS, CE marking, or ISO 9001. Consider also local standards in case you operate outside the home country. Say any safety needs, such as fire-resistance or toxic concentration levels. Suppliers then know what's obligatory, and it helps save your hide at the time of audit, product inspection, or contract check.

Packaging and Labeling Instructions

Once the product is manufactured, how do you want it to be shipped? If you don't indicate packaging, the vendor may package it in a manner that causes damage or confusion. Should it be palletized, boxed, or vacuum-sealed? What about the labels—do you want batch numbers, country of origin, expiration date, or storage instructions? These details assist in ensuring easy inspection, correct inventory handling, and a hassle-free procurement process from beginning to end.

Inspection and Testing Criteria

Prior to signing off on a shipment, the materials must go through your inspection procedure. Specify what testing should be conducted, how often, and by whom. Do you anticipate third-party laboratory testing, or is an internal inspection sufficient? Should you require a certificate of analysis (COA) on every batch? Adding specific procedures and key criteria such as X-ray fluorescence or tensile testing brings clarity. It ensures materials conform to the stated specifications, and it maintains quality in check.

Writing detailed specs is step one, sourcing from suppliers who follow them is step two. With Torg, discover global manufacturers that meet your exact requirements, no compromises. Whether for private label or direct sourcing, we’ll simplify your process. Sign up and get matched with trusted partners today.

Why Material Purchase Specifications Are Critical

When you're procuring materials for a project or expanding production, it's tempting to regard material purchase specifications as just one more piece of paper. But they're so much more than that. A good specification prevents headaches and makes everything go smoothly. Here's why a solid specification is important.

Ensuring Product Quality and Performance

Picture it: You receive the raw materials, but they aren't what you wanted. Perhaps they're brittle, not as durable, or the wrong color. That's where material specifications fit in. They establish the standard for the way the material performs. Whether it's looks, durability, or performance, a good spec guarantees that you're receiving just what you require every time. No surprises.

Reducing Supply Chain Risk

A bad or ambiguous material specification can create supply chain risks. Perhaps the material is not up to standards or the supplier gets it wrong. The outcome? Delays, rework, recalls, and even regulatory breaches. By being clear about what you need from the beginning, you're minimizing the likelihood of things going awry. This keeps your procurement process efficient and cost-effective.

Enabling Consistency Across Suppliers

What happens when you’re working with more than one supplier? Without clear specifications, you’re at risk of receiving different quality levels from each one. A solid material purchase specification ensures that no matter who you’re working with, they’re all on the same page. It makes it easier to compare quotes, assess samples, and keep things consistent in both procurement and production.

Facilitating Regulatory Compliance

If you're in a business such as medical devices, food, or automotive, you understand how rigid the regulations are. Material specifications ensure that your raw materials meet safety standards and legal requirements from the beginning. By defining everything up front in the specification development stage, you prevent compliance problems later on. That way, you won't be surprised by an audit or a legal issue down the road.

How to Write a Material Purchase Specification

Assembling a crisp material purchase specification doesn't need to be intimidating. It requires a little bit of planning, collaboration, and being aware of what to observe. If you are a buyer, engineer, or sourcing manager, this segment of the purchasing process is where you lay down the groundwork to acquire the materials you really need.

Define Technical Requirements

Begin with the technical spec. What do you want the material to accomplish in your project or product? Consider its performance—must it be heat resistant, flexible, waterproof, or chemically inert? Must it have a special finish or hue? Be definitive about both functional and aesthetic expectations. These particulars assist in ensuring your supplier will provide what you truly require, not merely what they think you desire.

Consult with Engineering or R&D

Your R&D or engineering groups have the know-how to identify problems ahead of time. They know the particular steps that the raw materials will be subjected to during production, and what might go awry if the material itself isn't quite correct. Ask them questions such as critical dimensions, load-bearing requirements, or failure-prone areas. Incorporating their input into your specs creates a robust document and minimizes late-stage surprises.

Reference Industry Standards

Where possible, reference your material specifications to published standards such as ISO, ASTM, or DIN. These are a common tongue between you and your prospective suppliers. Rather than attempt to detail all properties by hand, you can point to an existing published standard that will do the work for you. This is particularly useful when selecting suppliers, as it minimizes miscommunication and establishes clearly defined expectations across borders and languages.

Include Inspection and Testing Methods

A good spec also states how the material will be tested. Will you visually inspect, send to a lab for testing, or use certain equipment to measure hardness or tensile strength? Describe when and how testing will occur—prior to shipping, in production, or upon arrival. Also state what type of documentation you anticipate, such as certificates of analysis or compliance reports. These steps facilitate quality control and protect your staff from expensive production errors.

Collaborate with Suppliers for Feasibility

Don't presume that whatever you write is immediately feasible. Give the draft to your supplier at the specification stage. Inquire whether the material, packaging, or tolerances are feasible for them to supply in volume. Early consultation can be cost-saving and prevent late-stage changes to your buying specification. Some suppliers might also provide useful innovations or cheaper materials depending on what's possible. Involve them as a partner in the process.

Common Mistakes to Avoid

Even the most skilled professionals err sometimes when preparing material specifications. Here's how to avoid it.

- Being Too Vague or Too Restrictive: Omitting essential details (or including too many too-frivolous ones) can both cause confusion. A loose specification invites misinterpretation, whereas too stringent criteria unnecessarily restrict supplier choice.

- Ignoring Supplier Capabilities: Don't presume that all suppliers are capable of meeting your spec. In finishing your document, research undertaken should encompass an awareness of what is possible in the supply marketplace.

- Missing Compliance Elements: Omitting safety standards or certifications can lead to regulatory infractions. Always check compliance requirements for your region, product, and industry.

- Not Updating Specs Regularly: Technology, regulations, and materials evolve. Specs that worked last year are outdated today. Ongoing updates are necessary to remain in conformance and competitive.

Best Practices in Managing Material Specifications

Drafting a material purchase specification is just the start. Maintaining it current and accessible is equally vital.

- Put Everything in One Location: Employ a common digital platform to house your specifications. When your organization, from engineering through procurement, can easily access the most recent technical specification or design specification, you eliminate misunderstandings and delays.

- Review Specs Regularly: The materials, suppliers, and requirements change. It is a good practice to periodically review your specs. Confirm whether your dimensions, performance targets, or compliance requirements are still current. This prevents issues at production or visual inspection time.

- Version Control over Track Changes: Things do go wrong. By using version control, you have a record of which document was current at any given time. If something is amiss, you can backtrack to the very version that was in use.

- Make Specs Easy to Read: All who will be utilizing the spec (from the user to the builder) need to be able to read it. Provide precise descriptions, drawings, and safety specifications. If everyone can actually use a well-written specification, it is a valuable resource.

Material Specification and Supplier Selection

Selecting the correct supplier is not solely based on money. It begins with the material purchase specification. When you issue an RFQ, your specification informs suppliers of exactly what you require. Whether it is raw materials, technical specification, or safety standards, they must meet it.

How do you know whether a supplier is suitable? Request samples, certificates, or test reports. Their willingness to agree to your specifications says a lot. This is where your specifications as a filter come into play. If they can't deliver to spec, they're not your people.

For your private label product, your specification also safeguards your brand. It ensures that your quality, performance, and compliance standards are known to possible suppliers. During the procurement process, an explicit specification reduces risk and saves you time by making supplier selection more efficient and objective.

Purchase Specification vs. Product Specification

These two main types of documents tend to be confused with each other but aren't identical.

A material purchase specification refers to the raw materials or parts you have to purchase. It details such things as size, strength, finish, and technical specifications the material must comply with.

A product specification, however, explains the final product. It specifies how the product should look, function, and behave once complete.

You can use both simultaneously. The material specification will direct what goes into the product, while the product specification ensures the final product fulfills your objectives. You could say the purchase spec is a step along the way to creating something that functions correctly and lasts.

How to Communicate Specifications to Suppliers

Putting your material purchase specification into writing is half the battle. Next up? Ensuring your supplier actually gets it. Effective communication can prevent time wastage, cost overruns, and much to-and-fro.

Here's the guidance to get it right:

- Put specs in key documents: Append your material spec to documents such as RFQs, purchase orders, or supplier agreements. This puts everyone on the same page from day one.

- Employ drawings or pictures: Have a CAD file or drawing? Send it along. A good picture or sketch can convey details that words often can't. It allows the supplier to see exactly what you're looking for.

- Translate when necessary: If your supplier is not local, think about getting your specification translated or using localized terminology. It saves confusion and makes it simpler for their staff to implement.

- Double-check understanding: Request your supplier to go over the material specification and assure them they are okay with it. A simple sign-off or acceptance prevents problems when production is underway.

This all assists in trusting your supplier and reducing miscommunication. It also assists in easier production and improved outcomes.

Auditing and Verifying Supplier Compliance with Specs

So your supplier has signed off on your material purchase spec. Wonderful—but how do you know they're really adhering to it?

You'll need to check in periodically. This allows you to catch issues early and keeps your materials consistent.

Here are a few real-world ways to do it:

Visit the factory or send someone to go

Other times, the best thing to do is to look at the factory in person. Alternatively, you can hire a third-party audit firm if you cannot attend yourself. They'll examine activities such as production processes and material handling to ensure your requirements are being met.

Request Certificates of Analysis (COAs)

A COA is a document that indicates whether a batch conforms to your material specification. Suppliers can include these with every shipment. It's an easy way to monitor quality without guessing.

Do your own testing if necessary

If you're particularly concerned, mail a sample to an independent laboratory. This comes in handy when you're dealing with performance materials or regulated products.

Monitor any issues and follow up

If it doesn't comply with spec, don't fix it and forget it. Document it, determine why it happened, and get the supplier to correct it so that it won't reoccur. This prevents future problems.

Periodic checks for compliance keep your product stable and your customers satisfied. They also safeguard your company against returns, recalls, or other expensive issues.

Conclusion

Writing a material purchase specification is not something to be rushed through. It's how you ensure your relevant materials are correct, your suppliers know what you need, and your product does what it's supposed to do.

Every line you add—whether you're talking about size, strength, or testing—gives your suppliers and your team something concrete to work with. When everyone has clear expectations, you save time, eliminate errors, and make better buying decisions.

As your processes, products, and services evolve, don't forget to revise your specs as well. Keeping them up to date keeps you competitive and your supply chain in motion.

A well-organized, well-managed specification can really make a difference in terms of quality and cost. So handle it like a critical component of your product, because in many respects, it is.

Request a Bulk Order Quote

Simple ordering, transparent pricing, delivered straight to your door