Buy Direct from Manufacturers: When It Works & When Not

Learn how to buy direct from manufacturers, avoid middlemen, and tap into private label sourcing with this detailed retail product sourcing guide.

200+ buyers trust Torg for sourcing

Considering cutting out the middleman? Whether you run an online store or keep shelves stocked in a physical store, buying direct from manufacturers can be a huge deal for you. When you purchase wholesale direct or purchase products directly from manufacturers, you're not merely cutting costs, but gaining control.

No more overpriced products or delayed stocks. Looking to purchase directly from a factory with low MOQ vendors? Or perhaps you are looking at private label sourcing in order to establish your own brand? This guide takes you through direct buy from manufacturer alternatives, so you can import for resale with ease. It's all about creating genuine relationships with wholesale suppliers for retailers and making better supply chain choices.

What It Means to 'Buy Direct from Manufacturers'?

"Buying direct from manufacturers" means purchasing goods straight from the company that produces them, without intermediaries such as wholesalers, distributors, or retailers. This approach is also often known as the "direct-to-consumer" (D2C) model, in which the manufacturer sells products straight to the final customer.

Suppose you're looking to import products for resale. Doing it directly from the factory implies less markups and greater leeway for making profit. And if you're a private label buyer, this is how you can adjust packaging, formulas, or designs without having to wait for a middleman to respond. This approach is particularly convenient if you're developing your own brand and require control right from the first day. Sounds appealing? That's because it typically is.

Manufacturer vs. Distributor vs. Wholesaler

Not quite sure who to purchase from? Let's dissect. Here's the rundown on manufacturers, distributors, and wholesalers and what it actually means for your control and margins.

Manufacturer

A manufacturer is the source of production—the company responsible for creating products from raw materials through machinery and industrial processes. Manufacturers manage the entire production cycle, from sourcing materials to assembling and packaging the final goods.

Mostly to big buyers such as wholesalers and distributors. But times have changed. Now even small retailers can buy directly from factory through worldwide platforms. Which means more companies can purchase goods directly from manufacturers and avoid the additional charges.

Pros:

- Best pricing when you cut out the middleman

- You are able to customize specs for private label purchasing

- Greater control over supply chain

Cons:

- Higher MOQs (so not for super tiny orders)

- You manage logistics and quality inspections

- Lead times may be longer

Distributor

A distributor is a company or individual that buys products in bulk from manufacturers and sells them to retailers, wholesalers, or end customers—often in smaller quantities. Distributors act as a middle link in the supply chain, helping manufacturers reach a broader market without managing direct sales themselves.

If you are not yet ready to purchase directly from manufacturers yourself, a distributor may be a stepping stone.

Pros:

- Lower MOQs than wholesale direct from factory

- Logistics support, delivery, and sometimes after-sales support

- Fewer variables—better for new retailers

Cons:

- You're paying a markup, which eats into your margins

- Customization? Pretty unlikely

- Less insight into who really produced the product

Wholesaler

A wholesaler is a business or individual that buys products in large quantities from manufacturers or distributors and resells them in smaller quantities to retailers, resellers, or other businesses. Wholesalers typically do not sell directly to consumers—they operate in the business-to-business (B2B) space.

Pros:

- Quick delivery and available stock

- Less commitment, perfect for low-volume buying

- Easy to locate and deal with

Cons:

- Prices marked up a second time, highest price in the supply chain

- No control over product package or design

- You don't establish a direct connection with the manufacturer

Knowing whom you're purchasing from (whether a distributor, wholesaler, or going directly to private label manufacturers) can completely flip your business model on its head. The more direct your source, the more leverage you have on pricing, branding, and supply chain transparency.

Who Should (And Should Not) Buy Directly From Manufacturers

It's not necessary for every retailer or importer to be capable of factory-level sourcing. Directly working with a manufacturer offers you a greater command, a better understanding, and a bigger space to develop a product line that appears to be intentional. But it also adds responsibility. You take on longer lead times, shifting freight conditions, and the kind of planning wholesalers normally handle for you.

One thing is clear: this route works best when you already understand how demand behaves and how supply chain timing can change without warning.

You should consider buying direct from factory if you:

- Handle moderate to large volumes without stressing your operations.

- Have predictable demand, or at least steady sales cycles.

- Can manage warehousing, storage, and longer inventory turns.

- Want tighter relationships with private label manufacturers.

- Prefer shaping product specs, packaging, or formulas.

- Are comfortable planning months ahead instead of reacting week by week.

You may not be ready for a direct purchase from manufacturer approach if you:

- Have no sales history for the product you want to import.

- Rely on fast restocks, quick turns, or minimal inventory.

- Do not have the cash flow to place larger upfront orders.

- Lack warehouse space, or depend on just-in-time delivery.

- Are still experimenting with product-market fit.

- Are unsure how freight, compliance, or customs work.

It is perfectly fine to start going through wholesalers or distributors while you figure out the behavior of your market. Direct sourcing then becomes a growth tool when you have your figures under control, your storage is in order, and your demand pattern is clear. It allows you to lower your margins, improve your consistency, and have more control over the development of your products.

Why Buying Directly from Manufacturers?

Why make the effort to go direct? Because it can really increase your control, savings, and flexibility when you purchase direct in bulk or buy wholesale direct. For many retailers, getting closer to the source just makes more sense. You see what’s happening, you understand the real costs, and you can actually shape the product in ways middlemen can’t offer.

Better Pricing & Larger Margins

Buying direct often changes the math entirely. Instead of absorbing multiple layers of added cost, you’re working with the original price which is the number the factory actually charges. Even a slight price drop makes a noticeable impact once orders scale. Paying closer to the factory’s base cost gives you extra room to maneuver, whether that means testing new price points, running small promos, or simply protecting your margin. It keeps your numbers stable without forcing you to cut corners elsewhere.

Customization (White Label / Private Label Options)

Direct factory access lets you influence the product before it ever reaches your shelves. You’re able to request small changes or new versions that better suit your buyers, instead of settling for ready-made items that dozens of retailers already carry. The process feels more collaborative, almost like building your own line from the ground up. For retailers aiming for differentiation, this level of customization becomes a meaningful advantage.

More Control Over Supply Chain

Factory-direct purchasing gives you more influence over how things move. You can check lead times, materials, and production schedules without waiting on updates from intermediaries. This visibility helps you plan stock more accurately and avoid sudden shortages. Actually, having direct insight helps you react quicker when demand shifts or when timelines need adjusting. It’s a smoother, more predictable approach to building reliable supply.

Direct Communication for Faster Issue Resolution

When you purchase merchandise directly from the makers, communication becomes clearer and faster. You talk to the people who actually understand the product, not someone relaying messages. If something goes wrong — maybe packaging, timing, or a small design detail — you can resolve it immediately. That direct line saves time, reduces frustration, and ensures you maintain consistent quality without unnecessary delays.

Is It Cheaper to Buy Direct from Manufacturers?

Generally, yes. When you purchase direct in bulk or purchase wholesale direct, you avoid those additional markups imposed by wholesalers or distributors. That typically translates to improved prices.

It's not always quite that straightforward, though. How much money you save depends on several things:

- Order quantity: Companies usually prefer you to buy products directly from manufacturers in larger quantities to be able to offer the best price.

- Custom work: In case you desire to modify formulas or packaging via private label manufacturers, setup fees may accumulate.

- Shipping and duties: Buying abroad? Import duties and freight may nibble away at your savings.

The key is to calculate the cost, i.e., include warehousing, shipping, and customs. Still, when you buy products directly from manufacturers, the unit cost usually lands lower. Sometimes 10–30% lower, depending on category and volume. Nevertheless, for the majority of retailers with an interest in retail product sourcing, factory direct buying offers the greatest long-term value.

Risks of Buying Directly from Manufacturers

Buying factory direct can work incredibly well, but the process isn’t foolproof. When you buy direct from manufacturers, you’re closer to the source, and that means you also see the parts wholesalers usually protect you from.

Communication Gaps

Working directly with a factory can feel smooth at first, but small misunderstandings easily slow things down. A missed detail, a vague instruction, or a time-zone delay can shift production by days. You need clear documents, shared references, and steady follow-ups. Basically, communication becomes part of the job when you buy direct from manufacturers, not an afterthought handled by someone else.

Quality Inconsistencies

Initial samples often look polished, yet full runs don’t always match that standard. Maybe materials change slightly or a new technician handles production. Without checks in place, quality can drift. Retailers buying direct from factory usually rely on third-party inspections or repeat sampling to keep things consistent. It’s not about distrust; it’s about ensuring every batch meets the level customers expect.

Scams or Non-Compliant Suppliers

Not every “factory” online is what it claims to be. Some listings belong to trading companies pretending to be manufacturers, while others operate without proper certifications. This creates risks for retailers who want to import products for resale. Asking for certifications, factory footage, and proof of compliance helps you separate real manufacturers from risky ones. When you cut out wholesalers, doing this extra homework isn’t optional as it is what keeps your supply chain stable.

Longer Timelines

When you handle sourcing yourself, you feel delays more directly. Factories deal with shifting schedules, material shortages, and shipping slowdowns that wholesalers normally cushion. If your business needs quick turnarounds, these gaps can be challenging. Building buffer time into every order becomes necessary, especially when production happens in regions where transit times can change without warning.

📦 Torg handles communication, quality checks, compliance, and logistics so you don’t have to sweat the details. 👉 Work with us today and focus on growing your business while we take care of the heavy work.

Request a Bulk Order Quote

Simple ordering, transparent pricing, delivered straight to your door

How to Buy Directly From Manufacturers

1. Define What You Need

Before you leap into searching, give yourself a minute to get definite on what you want. Jot down your product specifications, your thoughts on packaging, and your minimum order quantity that you can handle. Don't go without noting your target price and how quickly the products need to be shipped. Having these things in mind upfront makes everything a breeze.

2. Search for Manufacturers

Where do you get the correct manufacturers? The best method is to make use of verified sourcing platforms like Torg. It's meant to directly connect you with manufacturers, private label suppliers, and wholesale distributors, eliminating guesswork.

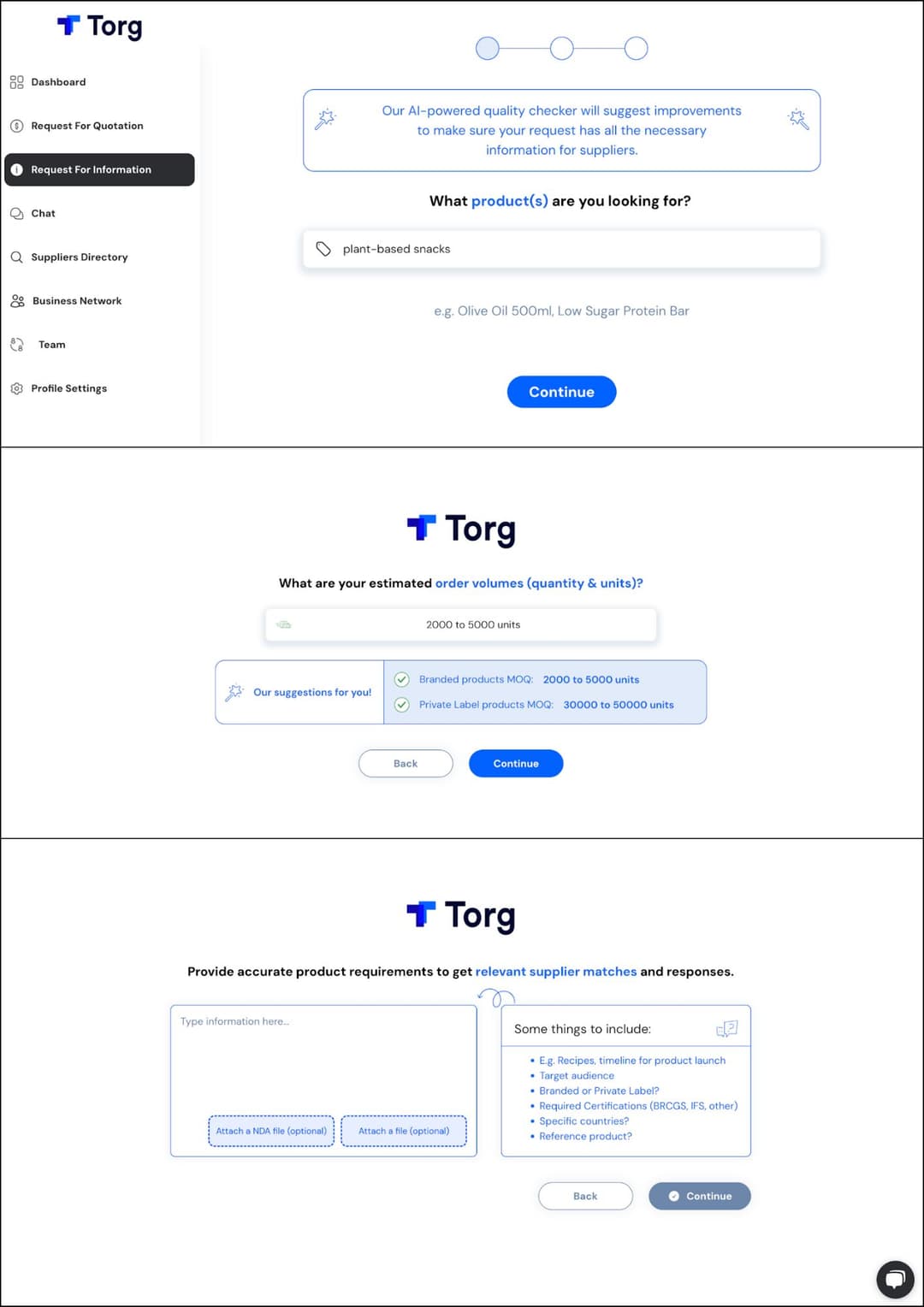

Don't know where to begin? Here is a brief step-by-step:

Sign Up for Free

Head over to usetorg.com and create your account in just a few clicks. It’s free and super quick.

Type in What You’re Looking For

Be specific! Whether it’s “plant-based products,” “private label snacks,” or “low MOQ granola,” the more details you give, the better.

Add Your Estimated Order Volume

Tell Torg if you want a few hundred units or a full pallet. This helps match you with suppliers who can meet your needs.

Provide Key Details

Got custom packaging, allergen-free ingredients, or other special requests? Add those in. It makes your matches more precise.

Let Torg’s AI Do the Work

Torg’s AI assistant, Sophia, will sift through verified suppliers and find the best matches for you.

Explore on Your Own, Too

Want to browse suppliers manually? Use the “Supplier Directory” tab to check out 150,000+ verified European manufacturers offering private label and bulk options.

Using Torg means you’re not just sending out random emails. You’re tapping into a smart platform built to connect serious buyers with trusted manufacturers quickly.

3. Verify the Manufacturer’s Credentials

Trust is very, very important. So always request a business license, factory inspection reports, and certificates such as ISO or HACCP if you're in the food or cosmetics industry. If you prefer additional peace of mind, ask for video tours or third-party audits. It keeps you away from scams and helps you identify trustworthy partners.

4. Initiate Contact and Ask the Right Questions

Don't simply ask, "How much does it cost?" Drill deeper. Ask lead times, private label assistance, MOQ on custom orders, and shipping locations. These inquiries demonstrate how flexible and seasoned your manufacturer actually is.

5. Negotiate Terms Clearly

Don’t stop at price. It's only one aspect of the transaction. Ask, "How do you want to be paid. Via LC, TT, PayPal?" Ensure packaging conforms to your specifications, labeling adheres to local regulations, and there are definite ramifications if they fail to meet deadlines. Food and drink makers value clarity as well, it benefits both parties.

6. Order Samples First

Don't miss this! It's your preview before the main event. Try the product yourself. Is the construction stable? Is everything it needs on the label? Is the packaging durable? Is shelf life good? When doing private label arrangements or dealing with low MOQ factories, samples are your step of quality control.

7. Place a Small Initial Order

Why be hasty and do a colossal shipment? Begin with a pilot batch. It's the logical method to validate consumer demand, determine if the quality lasts in the long term, and analyze how responsive your supplier actually is. Most food and beverage products have trial runs, particularly manufacturers who are willing to do low MOQ and startup collaborations.

Questions You Should Ask Before Buying Direct

Considering purchasing directly from manufacturers? Great! But hold off for a moment and consider asking these vital questions to prevent surprises:

- "Do you have private label or white-label options?" Can you modify the product to align with your brand?

- "What's the MOQ of your regular stock? And for custom orders?" You need to know whether your order quantity aligns with their minimums.

- "Are your products certified?" Such as ISO, HACCP, or anything demonstrating quality and safety.

- “Can I visit your factory or get a third-party inspection?” Seeing is believing, right?

- “How long does production usually take?” So you can plan your inventory and sales.

- “What payment methods do you accept?” Is it wire transfer, PayPal, letter of credit—what works best?

- “What if there’s a delay or a problem with the goods?” How do they handle issues or returns?

- “Do you handle international shipping and customs?” This can save you a headache if you’re importing.

Having these questions upfront allows you to develop a good relationship with your manufacturer and ensures your supply chain remains smooth.

Top 10 Food & Beverage Manufacturers in Europe

1. SVZ – Netherlands

SVZ is a leading food and beverage producer in Europe, and they've been doing it for more than 150 years. Fruit and vegetable ingredients—100% natural—that's their specialty. They produce everything from juices and purees to frozen mixes. Need clean-label ingredients and bulk sourcing executed perfectly? SVZ is the way to go.

2. ICHOOSEITALIA SRL – Italy

I Choose Italia makes it possible for importers to find authentic Italian tastes directly from the source. Cheese, cured meats, olive oils, wines, and more. The best part is that they specialize in matching buyers with enthusiastic, small-batch manufacturers. Perfect if you're on the hunt for private label items or artisanal products that will stand out on shelves.

3. Danish Contract Production APS – Denmark

Need a flexible manufacturing partner in North Europe? Danish Contract Production may be your perfect match. They provide contract manufacturing of food and beverage products with rapid lead times and plenty of packaging variety. Think of them as your behind-the-scenes production staff doing all the filling, mixing, labeling, and even warehousing. Perfect for smaller brands who want to grow without having to establish their own facility.

4. Gemak UK – United Kingdom

Gemak isn’t your average manufacturer. They build the actual machines that process your food and beverages, from pasteurizers and heat exchangers to custom tanks. If you’re into dairy or ready-to-drink beverages, they’ve likely got a solution for you. They also offer custom engineering services, so whether you’re setting up a new production line or optimizing an existing one, Gemak has your back.

5. Ilgezeem, SIA – Latvia

Ilgezeem mixes old-school recipes with modern production tech to create unique drinks that stand out. Their range includes kvass (a fermented drink), malt beverages, sodas, cider, beer and even sauces like tomato ketchup. They’re a solid option if you’re looking for Eastern European flavor profiles or want to diversify your drink lineup with something a little unexpected.

6. Dole Sunshine Company – Germany

You may have noticed Dole's fruit bowls or canned pineapple on grocery shelves—but did you know they're also innovating sustainable food too? Headquartered in Germany, Dole is one of those food and beverage companies doing more than quantity production. They transform fresh fruits into snacks, beverages, and even specialty ingredients such as pineapple fiber powder. They're ideal if you want to support sustainable practices and source from a brand that practices what it preaches.

7. Galafrut Private Enterprise – Ukraine

Need that perfect berry topping or fruit syrup to level up your product? Galafrut’s got you. They’ve been making flavor-packed fillers, jams, and syrups for over 14 years. Think smoothies, yogurt, desserts, and more. They’re great for private label brands looking for bold, fruity flavor and the flexibility to customize. Bonus: they’re super familiar with low MOQ production, which is great if you’re starting small.

8. Carnevale – United Kingdom

Family-owned, Italian-food-passionate, and downright excellent at their job—Carnevale is your favorite Italian deli, but national. They produce and distribute it all, from filled pastas and cheeses to bakery products and cured meats. If you're a retailer or restaurant interested in private labeling traditional Italian products, Carnevale's blend of heritage and creativity puts them firmly in the running.

9. Miller Food Service – United Kingdom

Operating a foodservice business or catering company? Colin Bussey Limited understands the grind. They provide everything from meat and dairy to frozen foods and drinks—solid prices across the board. What they excel at is their dependability and customer service. Need consistent quality and not the headache of dealing with five different vendors? This may be your go-to stop.

10. Colin Bussey Limited – United Kingdom

Here's a name you don't get to hear every day—but in the realm of food innovation, Colin Bussey Ltd is a household name. They don't just produce food—they create experiences. From bespoke recipe development and private label production to full-on culinary consulting, they're perfect if you want to introduce something new to the table (literally). Best for hotels, fine dining restaurants, or anyone who wants to add a premium touch to their brand.

FAQs

1. Can I buy small quantities directly from a manufacturer?

Absolutely! If you're searching for low MOQ suppliers, most manufacturers these days have smaller batch sizes available—ideal for startups or specialty brands feeling out the waters.

2. What certifications should manufacturers have?

It will vary by industry, but typical ones are ISO 9001, GMP, HACCP, BRC, CE, or USDA Organic. They indicate the factory is in compliance with quality, cleanliness, and safety standards.

3. How do I verify a manufacturer’s credibility?

Always request business licenses, third-party audit reports, and check online for reviews. Sites such as Torg can also be used to verify suppliers. A factory visit, if possible, or a third-party inspector can be hired for peace of mind.

4. Do manufacturers handle shipping and customs?

Sometimes they do, especially if they’re experienced exporters. It’s smart to ask upfront if they can manage shipping and customs or if you’ll need to organize a freight forwarder yourself.