How Product Digitization Transforms Brands and Supply Chain

Explore how product digitalization enhances performance, boosts supply chain efficiency, and unlocks growth through smart, connected products.

200+ buyers trust Torg for sourcing

The concept of product digitalization is gaining traction across virtually every industry. From manufacturing to retail, companies are looking to transform their traditional products into smart, connected assets. This shift goes beyond simply putting things online; it's about embedding digital capabilities into physical products to improve performance, enhance user experiences, and unlock new business opportunities.

Product digitalization plays a vital role in modern business and supply chains. It enables real-time data collection, process automation, and better decision-making, all of which are crucial in a globalized market where speed and adaptability are key. Whether you're a B2B supplier or a consumer goods manufacturer, digitalizing products can be a powerful lever for growth, efficiency, and sustainability.

What Is Product Digitalization?

Product digitalization is the process of enhancing physical products with digital technologies. This includes embedding sensors, software, and connectivity to allow the product to generate, collect, and transmit data throughout its lifecycle.

It’s important to distinguish product digitalization from related terms like digitization and digital transformation. Digitization is the conversion of analog data into digital format, while digital transformation refers to a broader organizational shift involving digital technologies across all operations. Product digitalization is a component of digital transformation, focused specifically on the products a business creates or uses.

Key components of product digitalization include:

- Data: Capturing usage, performance, and environmental data

- Software: Enabling smart functionality, updates, and analytics

- Sensors: Measuring physical conditions like temperature, motion, or location

- Connectivity: Allowing communication via Wi-Fi, Bluetooth, 5G, or other networks

Digitalized products in the supply chain include smart containers, RFID-tagged pallets, connected warehouse equipment, digital product passports, and IoT-enabled machinery. These technologies enhance visibility, automate tracking, and support real-time decision-making. They also improve supply chain traceability, reduce errors, and enable predictive maintenance, boosting efficiency and transparency across the entire supply chain.

Product Digitalization in the Supply Chain

Digitalization enhances every stage of the supply chain, from sourcing to delivery.

- Visibility: Products equipped with sensors provide real-time tracking across the supply chain.

- Traceability: Digital records help trace product origin and compliance, vital for industries like food, pharmaceuticals, and electronics.

- Efficiency: Automated alerts and condition monitoring reduce spoilage and improve delivery precision.

An emerging trend is the Digital Product Passport—a comprehensive digital record of a product’s lifecycle, materials, and compliance data. These are especially valuable for sustainability initiatives and circular economy strategies.

Why Is Product Digitalization Important?

Product digitalization is not just a tech trend—it's a strategic advantage. Companies that embrace it are seeing measurable improvements in several key areas:

- Operational Efficiency: Automated data collection and remote monitoring reduce manual processes and downtime.

- Product Innovation: Digitalized products can receive software updates or feature enhancements over time.

- Customer Satisfaction: With more usage insights, companies can personalize experiences and offer predictive maintenance.

Digitalization also boosts competitiveness. Companies with smart, connected products can offer service-based models, open new revenue streams, and respond faster to market changes.

How Does Product Digitalization Work?

Product digitalization works by adding smart technologies like sensors, software, and internet connectivity to physical products. These tools collect and share real-time data about how a product is used, its condition, or location. The data is stored and analyzed, often using cloud systems and AI, to help businesses improve performance, predict issues, and offer better services. Digitalized products can also connect to systems like ERP or supply chain software, making operations more efficient and responsive to customer needs.

Several advanced technologies make this possible:

- IoT (Internet of Things): Connects products to the internet to exchange data.

- Cloud Computing: Stores and processes large volumes of product data.

- AI & Big Data: Analyzes patterns, predicts behavior, and automates responses.

Digitalized products often integrate with existing enterprise systems like:

- ERP (Enterprise Resource Planning): For inventory, procurement, and finance alignment

- PLM (Product Lifecycle Management): To manage product development and updates

- Supply Chain Systems: For real-time visibility and demand planning

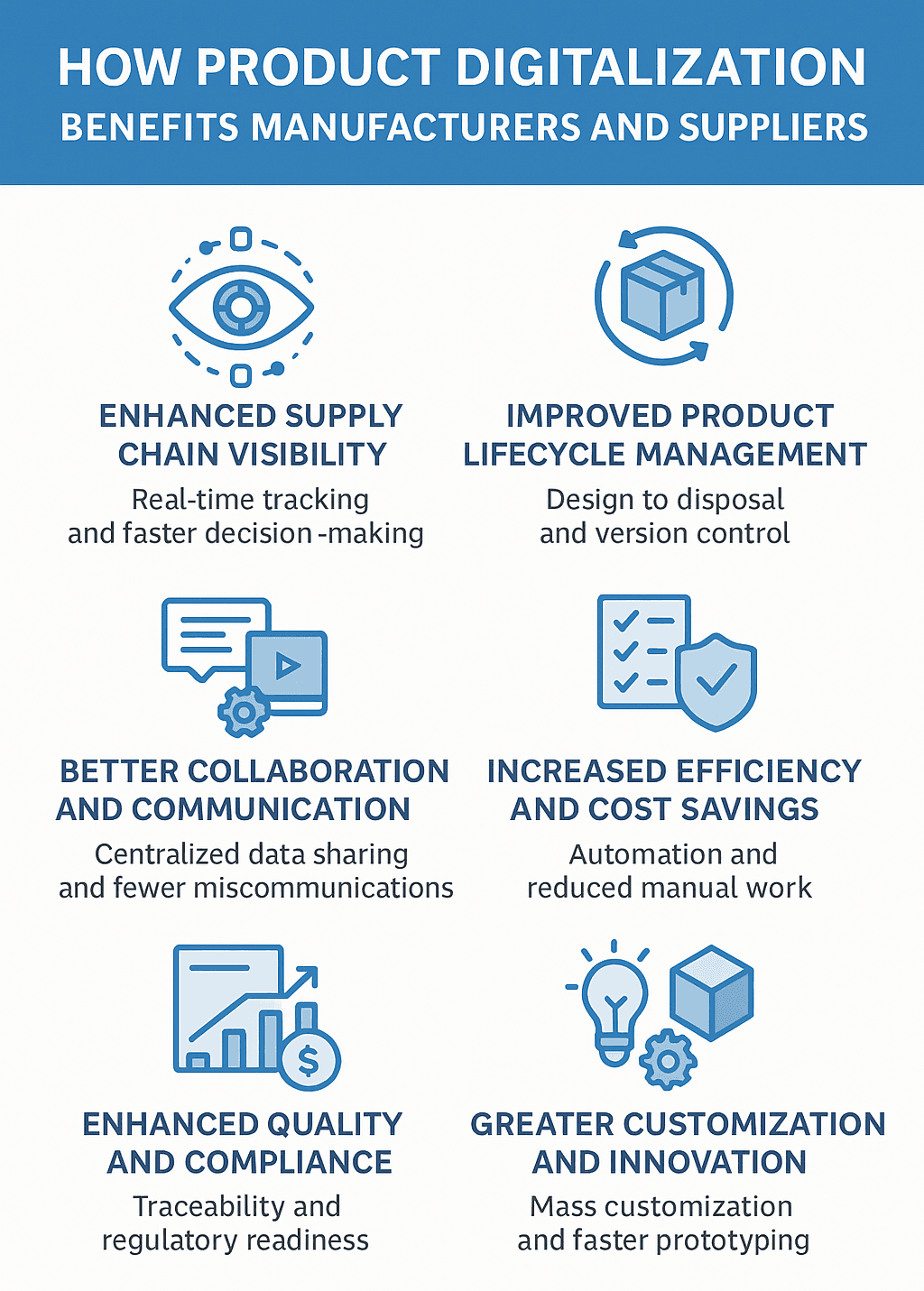

How Does Product Digitalization Benefit Manufacturers and Suppliers?

Manufacturers and suppliers stand to gain significantly from product digitalization:

Enhanced Supply Chain Visibility

With digital tools like sensors and digital twins, manufacturers can track every stage of production, inventory, and delivery as it happens. This real-time view helps them quickly spot problems—like delays or shortages—and make smart decisions right away. The result is a more responsive and reliable supply chain that keeps everything moving smoothly.

Improved Product Lifecycle Management

Digital product data helps manage every step of a product’s journey—from the initial design to when it’s eventually recycled. Updates and changes are logged automatically, so everyone involved stays on the same page. This prevents mistakes, keeps product information consistent, and supports long-term planning and sustainability goals.

Better Collaboration and Communication

When product details are stored digitally, they can be easily shared with partners, suppliers, and teams across the globe. This centralized access ensures everyone works with the same information, whether it’s blueprints, technical specs, or compliance certificates. By using standardized formats, there’s less confusion and fewer costly mistakes.

Increased Efficiency and Cost Savings

Digitalization cuts out repetitive manual tasks by automating things like order processing, quality checks, and compliance reporting. It also reduces paperwork and simplifies data entry. This saves both time and money, allowing teams to focus more on value-adding work rather than administrative tasks.

Enhanced Quality and Compliance

Every component in a product can be traced back to its source through digital records, which is crucial for quality control and dealing with recalls. Plus, storing important documentation digitally makes it easy to stay compliant with regulations. This is especially helpful during inspections or audits, where quick access to accurate information is essential.

Greater Customization and Innovation

With digital models, companies can tweak designs quickly to meet specific customer needs without starting from scratch. This makes it easier to offer personalized products on a large scale. At the same time, tools like 3D modeling and simulations speed up testing and development, so new ideas can be brought to market faster.

Key Technologies Driving Product Digitalization

Several key technologies are powering the digitalization of products:

- Internet of Things (IoT): IoT enables physical products to connect and communicate over the internet. This is the foundation of most digitalized products, enabling data collection and remote control.

- Artificial Intelligence (AI) and Machine Learning: AI helps interpret the data collected by digitalized products. From predictive maintenance to smart recommendations, AI brings intelligence to the system.

- Digital Twins: A digital twin is a virtual replica of a physical product or system. It allows for simulation, testing, and real-time monitoring without interfering with the actual product.

- Blockchain: Used for secure and transparent product traceability, especially in complex supply chains. It ensures data integrity and combats counterfeiting or fraud.

Biggest Challenges in Implementing Product Digitalization

Despite the benefits, several challenges can hinder implementation:

- Data Privacy and Security: Connected products generate sensitive data that must be protected against cyber threats.

- Integration Complexity: Combining new digital features with legacy systems can be difficult and costly.

- Cost and ROI Concerns: The upfront investment in technology and expertise may be significant, especially for small to mid-sized companies.

Companies must carefully evaluate their digital maturity, ensure staff training, and plan for long-term maintenance and support.

Best Practices for Successful Product Digitalization

Here are some best practices to ensure successful product digitalization for manufacturers and suppliers:

1. Start with a Clear Strategy

Define your goals before diving in. Whether you aim to improve efficiency, boost collaboration, or enhance product tracking, having a clear purpose will help guide your digitalization efforts and measure success.

2. Standardize Data Formats

Use consistent, interoperable formats like GS1, STEP, or XML for digital product data. This ensures compatibility across systems, reduces errors, and makes it easier to share information with partners and platforms.

3. Invest in Scalable Technology

Choose tools and systems that can grow with your business. Cloud-based platforms, IoT devices, and PLM (Product Lifecycle Management) software should be flexible enough to handle increasing data and evolving needs.

4. Ensure Cross-Department Collaboration

Digitalization affects design, manufacturing, quality, and procurement. Get buy-in from all relevant departments early and involve them in planning and implementation to avoid silos and ensure smooth adoption.

5. Prioritize Data Accuracy and Governance

Digital product information must be accurate and up to date. Assign ownership of data maintenance and establish rules for how data is created, validated, stored, and shared across your organization.

6. Integrate with Existing Systems

Ensure your digital product data connects smoothly with ERP, CRM, and supply chain platforms. Integration eliminates duplicate work, improves visibility, and supports automation.

Future Trends in Product Digitalization

Looking ahead, several trends are expected to shape the next wave of product digitalization:

- Hyperautomation: Combining AI, robotics, and low-code tools to automate complex product processes.

- Predictive Analytics: More advanced forecasting based on real-time and historical data.

- Circular Economy Integration: Designing products for reuse, remanufacturing, and recycling with full digital traceability.

As regulatory and consumer pressures grow, companies that align digitalization efforts with sustainability goals will have a distinct edge.

Conclusion

Product digitalization is transforming how businesses design, manufacture, and manage their products. By embedding digital intelligence into physical goods, companies can enhance performance, reduce costs, and build stronger customer relationships.

While the journey requires thoughtful planning and investment, the long-term benefits far outweigh the challenges. Whether you’re just beginning or scaling up your digital strategy, start with a clear vision, involve the right stakeholders, and build on small wins.

For those looking to take the next step, consider exploring platforms and tools that support IoT integration, cloud-based analytics, and digital twin modeling. Digitalization isn’t just the future—it’s the new standard.

Request a Bulk Order Quote

Simple ordering, transparent pricing, delivered straight to your door