What Is Air Permeable Packaging? Materials, Benefits, Uses

Air permeable packaging lets products breathe, keeping them fresher longer. Discover top materials, benefits, and suppliers for your business.

200+ buyers trust Torg for sourcing

If your products require protection from air, heat, or moisture, then packaging is not merely about enclosure, it's about management. Air permeable packaging is where this comes in. It's employed by brands shipping fresh produce, meat, seafood, or medication that cannot be sealed away and left to fend for themselves. These things must breathe. Packaging that permits oxygen, carbon dioxide, and even a bit of moisture to move in and out keeps them from rotting too quickly.

The smart breathable packaging cooperates with your product, not against it. They're not technical bells and whistles, they're functional aids that directly influence the appearance, taste, and shelf life of your product.

Up next, let's dissect the concepts: gas permeability, modified atmosphere packaging, and how to pair the appropriate packaging to the needs of your product. If your objective is to preserve quality while maintaining efficiency through the supply chain for your product, this is what packaging is about.

What is Air Permeable Packaging?

Air permeable packaging is a type of packaging material designed to allow controlled airflow—specifically oxygen, carbon dioxide, and sometimes moisture—between the inside and outside of a package. Unlike airtight or vacuum-sealed packaging, it supports products that need to “breathe”, such as:

- Fresh produce (fruits, vegetables)

- Meat and seafood

- Pharmaceuticals and medical kits

These products continue to emit gases and moisture after packaging. If sealed too tightly, it can lead to spoilage, mold, or reduced shelf life. Air permeable packaging uses materials like micro-perforated films, breathable papers, and mesh fabrics to manage gas exchange, humidity, and pressure. It’s a passive, low-maintenance alternative to more complex systems like Modified Atmosphere Packaging (MAP), making it ideal for cold chain logistics, agriculture, and eco-friendly retail.

How Air Permeable Packaging Works

Fresh food doesn't breathe only once it's packed. Produce, vegetables, and even meat give off carbon dioxide and require a constant supply of oxygen in order to remain fresh. If you lock that in a closed plastic bag, things rapidly deteriorate, moisture accumulates, mold takes hold, and quality decreases.

Air permeable packaging accomplishes that through the use of materials with precisely controlled oxygen, carbon dioxide, and air permeability. They're not haphazard, they're designed to allow just the right amount of airflow through to match the way the product behaves naturally. That translates into less pressure, fewer temperature fluctuations, and generally improved fresh produce storage.

Used in conjunction with a controlled atmosphere, in which gases within the package are deliberately modified, this system is even more effective. The packaging film serves as a guardian, controlling gas flow, slowing down rot, and maintaining the contents fresher for longer without the use of synthetic preservatives.

How Breathable Packaging Impacts Logistics and Cold Chain

In cold chain logistics, the issue isn't temperature, it's control. When you're transporting fresh produce, meat, or seafood, there's always risk: delays, heat peaks, or moisture buildup. That environment destroys quality in no time if your packaging doesn't breathe.

Breathable packaging makes all the difference. It controls oxygen levels, allows carbon dioxide to escape, and stabilizes the internal atmosphere in transit. That circulation of air avoids condensation, equalizes internal pressure, and prevents the type of spoilage that typically occurs before the product even hits the shelf.

Whether you're shipping goods internationally or just down the street, ventilation packaging accommodates the natural product behavior. It preserves freshness, minimizes waste, and provides a bit of wiggle room (literally) when everything doesn't work out as intended. Amidst a supply chain with so many variables, employing the proper breathable film or intelligent packaging is something you have control over.

Permeable vs. Non-Permeable Packaging

Not all products must breathe. Some require complete protection. Others require controlled ventilation. That's the fundamental difference.

Non-permeable packaging seals out air, water, and gases entirely. It's ideal for foods like snack foods, electronics, or anything that remains stable over time without requiring air. The intent here is complete isolation.

Air-permeable packaging is designed for products that are still active upon packaging such as fruits, vegetables, meat, or medicine. These products require a means for oxygen and carbon dioxide to travel in and out. If you seal them too tight, they degrade quickly, compared to non-permeable packaging.

Deciding between the two simply depends on what your product really requires. A microporous film, micro-perforated plastic, or anti-condensation bag may be best for some. Others will require complete barrier protection. The most important thing is knowing how air permeability affects shelf life, safety, and storage conditions.

Materials Used in Air Permeable Packaging

Air permeable packaging relies on specific materials that allow controlled airflow while providing protection from contaminants, moisture, or damage. These materials are carefully selected based on their porosity, strength, and application.

Paper & Fiber-Based Materials

Paper and fiber-based materials like kraft paper, crepe paper, and Tyvek® are widely used in air permeable packaging for their natural breathability and strength. These materials allow airflow while protecting contents from dust and contaminants, making them ideal for medical, textile, and dry goods applications. Nonwoven fabrics like polypropylene also offer excellent tear resistance and airflow, providing lightweight and reliable packaging for items requiring ventilation and sterility.

Perforated & Mesh Plastics

Perforated films and plastic mesh are common in air permeable packaging for food and produce. Materials like PE, PP, and PLA can be microperforated to extend shelf life by reducing moisture buildup. Plastic mesh bags provide full ventilation, perfect for packaging onions, garlic, and toys. These breathable plastic options combine durability and airflow, making them essential for perishable and bulky goods that need constant air circulation.

Natural & Biodegradable Materials

Natural options like cotton and jute mesh are sustainable choices for air permeable packaging. They are fully biodegradable and ideal for packaging fresh produce or reusable bulk bags. Biodegradable films, such as PLA or starch-based materials, also offer breathability while meeting compostability standards. These eco-friendly materials combine air permeability with minimal environmental impact, aligning with growing consumer demand for sustainable packaging solutions.

Laminated & Coated Composites

Laminated paper-plastic blends and breathable coated films offer selective permeability with added durability. These materials are ideal for medical and high-value products requiring controlled airflow and light moisture protection. Coatings like polyurethane or acrylic help maintain sterility while allowing gas exchange. This makes laminated and coated solutions a smart choice for specialized air permeable packaging that demands both performance and product safety.

Benefits of Air Permeable Packaging

Air permeable packaging is not only a technological advancement, it's a functional step that addresses genuine issues in freshness, safety, and waste. Following are ways it excels across various sectors and applications.

Prevents Condensation and Mold

Breathable packaging enables excess moisture to vent, reducing the risk of mold and microbial growth. When moisture is trapped within the bag, particularly during temperature rises, you achieve spoilage. Air flow helps regulate humidity and make your products safer throughout storage and shipment.

Extends Product Shelf Life

This type of packaging film facilitates natural respiration of fresh produce, meat, and seafood. It regulates oxygen and carbon dioxide permeability, which retards spoilage and maintains food fresh for longer. That's a huge advantage when shipping over long distances or dealing with inventory.

Maintains Product Freshness

By maintaining the internal environment in balance, breathable packaging ensures color, texture, and flavor protection. From transporting vegetables, fruits, or even perishable products, this air flow ensures quality is retained and the soggy, wilted appearance that discourages consumers is avoided.

Enhances Sterility in Medical Use

In medicine, air permeability is not a choice, it's vital. Materials which enable steam or gas to sterilize the contents without compromising the barrier. It's how surgical kits and delicate instruments are stored safely in hospitals and kept sealed and clean until their use.

Reduces Environmental Impact (when biodegradable)

Eco-packaging with compostable bags or light fiber films offers a crucial outer layer that reduces waste. Developed for gas control and shelf life, this range supports brands that are determined to cut plastic. Present analysis shows it's smart for product protection—and smarter for the planet.

Air Permeable Packaging vs. Vacuum & MAP Packaging

Vacuum and MAP (Modified Atmosphere Packaging) are their place, but they're not always the best fit, particularly for fresh, fragile products. Vacuum packaging method removes all oxygen, which is great for shelf life, but it also compresses soft fruits, vegetables, and seafood. That can crush or bruise the product.

MAP replaces the air with a special blend of gases, typically rich in carbon dioxide or nitrogen, to retard spoilage. It works well with meat and packaged products, but the package must be tightly sealed. Without permeable film, the inside can become pressurized or hold water, which is counterproductive quickly.

Air permeable packaging is more natural and easy. It allows oxygen and carbon dioxide to travel freely, accommodating fresh produce's natural breathing. Consider it as a low-maintenance, passive replacement for MAP, cost-effective, smart, and ideal for fresh produce, agricultural products, or anything that requires breathing.

5 Best International Packaging Companies

Looking for reliable partners in packaging? These top packaging companies lead the way with innovative, high-quality solutions tailored for food, pharma, retail, and more.

1. Cartotecnica Postumia S.p.A. — Italy

Cartotecnica Postumia is among Italy's leading paper packaging experts, favored by European brands for sustainable solutions. With custom paper bags through to industrial packaging, they aim for both style and strength—ideal for food, pharma, and retail industries that require breathable, sustainable materials.

2. TIKPACK — Ukraine

TIKPACK is a trusted food packaging firm that also produces cereals, sugar, and grains. Established throughout Europe for bulk packaging capacity, they provide versatile solutions such as private label packing and air permeable bags for moisture-prone products. Ideal for large-volume buyers.

3. Atlas Packaging — United Kingdom

Located in the UK, Atlas Packaging is a top corrugated cardboard packaging firm that does more than simply boxes. They offer bespoke, shelf-ready packaging and eCommerce packaging that survive real-world logistics. They also care about sustainability, making them a wise brand choice for companies going green.

4. Multeafil Sp. z o.o. — Poland

Multeafil is a Polish specialist tea packager with decades of experience. They understand how to maintain freshness through breathable film and bespoke cardboard structures. They provide from loose-leaf tea boxes to individually wrapped bags, ready to go for retail or export.

5. Unijapak D.O.O. — Serbia

Unijapak is a food packaging manufacturer with extensive knowledge in dry foods and spice blends. They have experience with handling soups, spices, teas, and instant food products, and they provide full-service packaging solutions for businesses intending to expand in the Balkan or wider European region. They are quality-oriented and poised to scale up.

MOQs for Air Permeable Packaging

Minimum order quantities for air permeable packaging may differ significantly based on what you are purchasing—materials, customization, and function. And there are just so many factors to consider so you may not anticipate a standard rate across the board. Here's a summary of what to anticipate:

- Custom breathable bags (for fresh produce, meat, or seafood): The MOQ for most suppliers is 10,000 to 50,000 units, particularly when branding or size differences are concerned.

- Biodegradable or compostable packages: These having more specialized processing, the MOQs will usually be higher, sometimes over 100,000 units based on the type of breathable film or anti-condensation packaging.

- Medical or pharma-grade packages: These are usually produced to suit particular devices or sterile kits, so MOQs are quoted specially depending on compatibility, barrier requirements, and air permeability specifications.

Don't order without samples. Test in your actual conditions, temperature fluctuation, pressure variation, and how it works during real distribution as these steps are very critical in the process. This way, the packaging material will suit your product, environment, and shipping process well.

Find the Right Packaging Supplier for Your Brand

If you're in the market for air permeable packaging, whether it's for fresh produce, meat, seafood, or medical products, you need partners who get what real-world conditions are like. That’s where Torg comes in.

Torg is a smart B2B sourcing platform designed for businesses that need reliable, verified packaging suppliers in Europe. Whether you're a startup looking for custom breathable bags or an established brand searching for private label packaging solutions, Torg helps you cut through the noise and connect with serious suppliers, fast.

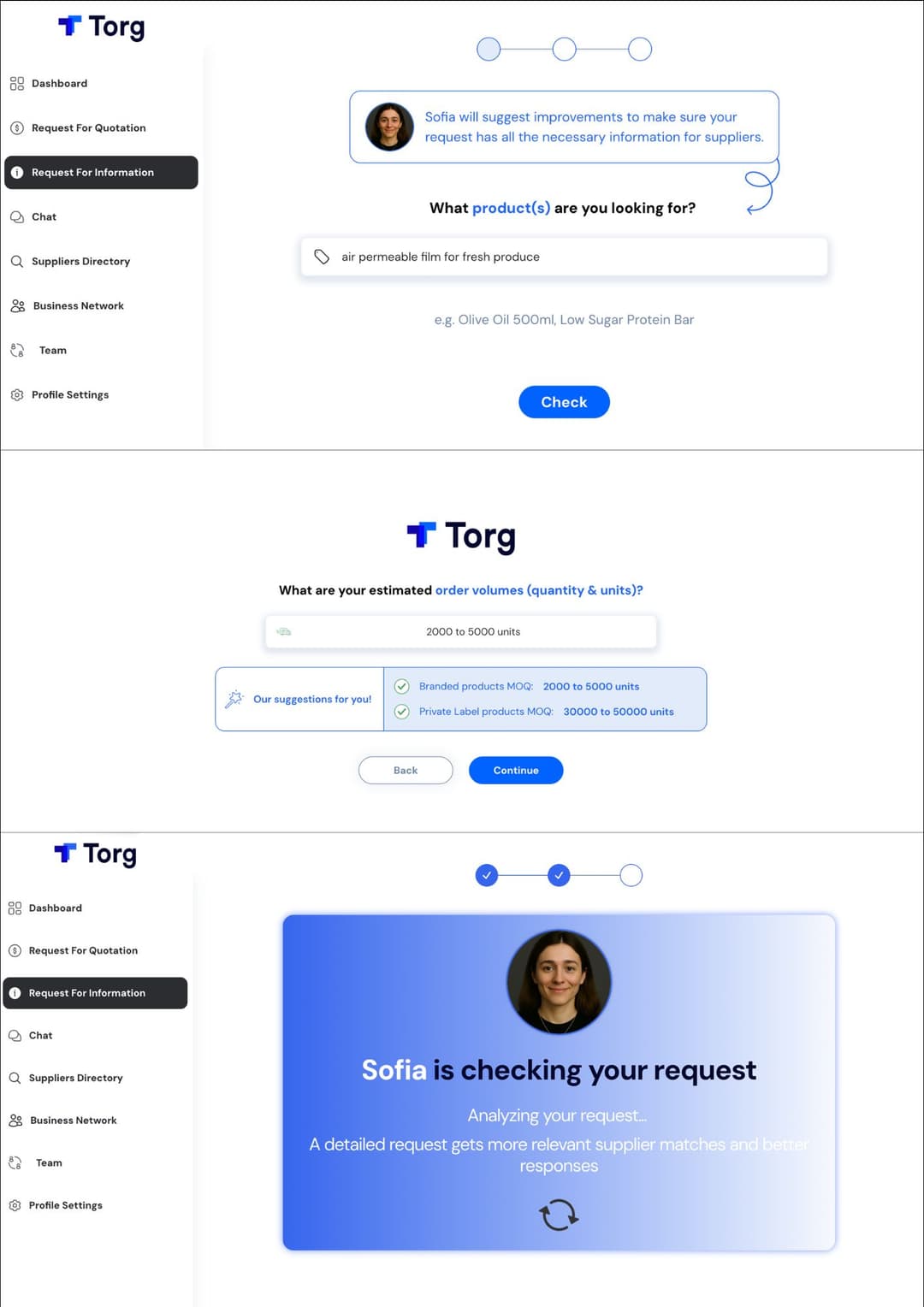

Here’s how it works:

Create a Free Account

Sign up now to get access to 150,000+ verified global manufacturers across different industries for free!

Send Your First RFQ

Be direct: “air permeable film for fresh produce,” “biodegradable packaging for medical kits,” or “compostable breathable bags for mushrooms.” The more details, the better your matches.

Add Order Volume + Special Requirements

Are you sourcing low MOQs? Need custom printing or specific oxygen permeability levels? Include it all in your brief.

Let the AI Get to Work

Torg’s smart assistant, Sophia, scans its network of verified packaging manufacturers and connects you with the most relevant ones.

Explore Manually if You Want

Torg also gives you access to a massive supplier directory. You can browse over 150,000 suppliers by product type, materials, certifications, and more.

No more cold emails or endless Google searches. Torg simplifies the sourcing process so you can focus on building a packaging system that’s smart, low cost, and right for your product.

FAQs

1. What is breathable packaging?

Breathable packaging is designed to allow air to flow in and out. Gases such as oxygen and carbon dioxide can pass through at levels that are regulated, keeping such things as fresh vegetables, meat, or vitamins stable, fresh, and safe in transport or storage.

2. Is air permeable packaging environmentally friendly?

Yes, if you choose the right materials. Compostable air permeable bags and bio-based breathable film are used extensively now as cleaner alternatives. They reduce plastic waste without sacrificing the ventilation your product requires. Just ensure they meet compostability or biodegradability criteria.

3. What industries use air permeable packaging?

It's large in agriculture, food, and pharmaceutical industries. Consider it anywhere items require airflow to remain fresh or sterile, such as fruit, seafood, or medical supplies. Ventilation packaging comes in handy when shipping temperature- or moisture-sensitive products.

4. Does air permeable packaging affect product shelf life

Absolutely. Respirable packaging retards spoilage by allowing your product to "breathe." It minimizes moisture accumulation, stabilizes air inside, and prevents the color, flavor, and texture from deteriorating, particularly with fresh foods, supplements, and anything edible.

5. Is air permeable packaging approved by FDA or EFSA?

Most breathable materials have already been cleared by the FDA and EFSA for safe contact with drugs and food. Nonetheless, don't take anything for granted, always request proof of certification from your supplier prior to ordering.

Request a Bulk Order Quote

Simple ordering, transparent pricing, delivered straight to your door