Beschaffung von Zutaten: Beste Praktiken, Herausforderungen und Checkliste

Entdecken Sie diesen Leitfaden zur Beschaffung von Zutaten, einschließlich bewährter Verfahren, Nachhaltigkeit, Rückverfolgbarkeit und Strategien zur Auswahl von Lieferanten.

200+ Käufer vertrauen Torg beim Sourcing

Die Beschaffung von Zutaten zeigt mehr über ein Unternehmen, als die meisten Menschen bemerken. Einige Teams erledigen dies still und leise, während andere ihren gesamten Prozess darauf aufbauen. Und in den Branchen Lebensmittel, Schönheit und Nahrungsergänzungsmittel tauchen immer wieder dieselben Themen auf: Konsistenz, Dokumentation und Vertrauen.

Jede Charge und jede Änderung des Ursprungs beeinflusst das Endergebnis. Clean-Label-Zutaten, Bio-Zutatenbeschaffung, ethisch beschaffte Zutaten und sogar gentechnisch veränderte Optionen durchlaufen dasselbe strenge System und sorgfältige Handhabung. Selbst geringfügige Änderungen könnten sich auf die Produktionszeitpläne auswirken.

Dieser Artikel beleuchtet die Details der Zutatenbeschaffung. Es spielt keine Rolle, ob Sie auf lokal beschaffte Zutaten oder globale Zutatenbeschaffung angewiesen sind, denn hier geben wir Ihnen einen Überblick über die besten Praktiken, Herausforderungen und wie verantwortungsvolle Zutatenbeschaffung dazu beiträgt, die Produktion organisiert, sicher und stabil zu halten.

Was ist die Beschaffung von Zutaten?

Die Beschaffung von Zutaten bedeutet, die Materialien zu finden und zu bestätigen, die in Lebensmitteln, Getränken, Nahrungsergänzungsmitteln und Schönheitsprodukten verwendet werden. Von außen scheint es schnell zu gehen, doch diejenigen, die es täglich managen, wissen, dass es weit mehr Schichten hat, als es den Anschein hat. Sie wählen nicht nur Lieferanten aus – Sie prüfen, wie Zutaten angebaut, gehandhabt und gekennzeichnet wurden, ob es sich um Clean-Label-Zutaten handelt oder ob sie aus gentechnisch veränderten Quellen stammen.

Jede Branche bringt ihre eigenen Anliegen mit sich. Lebensmittelmarken neigen zu ethischer Lebensmittelbeschaffung und Qualitätssicherung von Lebensmitteln. Hersteller von Nahrungsergänzungsmitteln legen Wert auf Wirksamkeit und Rückverfolgbarkeit von Zutaten. Schönheitsunternehmen suchen nach natürlicher Zutatenbeschaffung und nachhaltiger Zutatenbeschaffung von Bio-Lieferanten, die konsistent bleiben.

Mit der Zeit wird die Beschaffung zu einer Routine, die auf Forschung und Lieferantenüberwachung basiert. So stellen Unternehmen stabile Materialien sicher und folgen einer verantwortungsvollen Zutatenbeschaffung.

Warum ist die Beschaffung von Zutaten wichtig?

Die Beschaffung von Zutaten ist wichtiger, als die meisten Teams anfangs denken. Sobald man einen Schritt zurücktritt und beobachtet, wie Lebensmittel-, Schönheits-, Getränke- und Ergänzungsbetriebe täglich arbeiten, wird schnell klar, wie viel von einer zuverlässigen Zutatenbeschaffung abhängt. Eine verspätete Lieferung und alles gerät durcheinander. Ein Lieferant ändert eine Spezifikation, und die Formeln müssen angepasst werden. Warum hat die Zutatenbeschaffung so viel Gewicht?

- Menschen erwarten Klarheit: Die Bedeutung einer transparenten Zutatenbeschaffung setzt Marken unter Druck, offen zu bleiben. Die Menschen wollen klare Antworten darauf, was in ihren Produkten enthalten ist.

- Vorschriften entwickeln sich ständig weiter: Regeln zur Qualitätskontrolle bei der Beschaffung und Rückverfolgbarkeit von Zutaten ändern sich häufig. Wenn Lieferanten zurückfallen, spürt die Marke die Auswirkungen.

- Lieferketten reagieren auf alles: Wetter, Transportverzögerungen, politische Veränderungen – all dies kann die Beschaffung von Rohstoffen leicht stören. Das Gute daran ist jedoch, dass Teams, die global beschaffte und nachhaltig beschaffte Zutaten verwenden, sich meist schneller erholen.

- Nachhaltigkeit treibt langfristigen Wert an: Ethische Zutatenbeschaffung und Landwirtschaft mit geringer Umweltbelastung unterstützen Kostenstabilität und Umweltziele.

- Der Ruf steht immer auf dem Spiel: Ein einziges Beschaffungsproblem kann Rückrufe oder Vertrauensprobleme verursachen. Klare Beschaffung und verantwortungsvolle Beschaffung reduzieren dieses Risiko.

Arten von Zutatenquellen

Jede Marke hat ihre eigene Reise mit Zutaten, und diese Entscheidungen erzählen eine Geschichte, die Etiketten nicht vollständig erfassen können. Einige Wege sind reibungslos, andere erfordern mehr Arbeit. Wichtig ist, zu lernen, wie jeder Weg funktioniert, warum er wichtig ist und wie er saubere Zutaten, Lieferantenbindungen und langfristige Stabilität prägt.

Inländische Zutatenbeschaffung

Inländische Zutatenbeschaffung zieht Teams an, die Wert auf weniger Überraschungen, zuverlässige Lieferzeiten und einfache Kommunikation mit Lieferanten legen. Innerhalb desselben Landes zu bleiben, vereinfacht die Rückverfolgbarkeit und beschleunigt Qualitätsprüfungen. Es unterstützt auch lokal beschaffte Zutaten und ethische Lebensmittelbeschaffung für Marken, die eine engere Überwachung und vorhersehbare Arbeitsabläufe anstreben.

Internationale Zutatenbeschaffung

Internationale Zutatenbeschaffung wird relevant, wenn ein Produkt Materialien benötigt, die der lokale Markt nicht bietet. Artikel wie Botanicals, Kakao, Extrakte, Mineralien und Fair-Trade-Zutaten fallen in diese Kategorie. Sie eröffnet auch die Möglichkeit, global beschaffte Zutaten und Unternehmen mit nachhaltig beschafften Zutaten zu nutzen. Allerdings erfordert sie mehr Tests, zusätzliche Dokumentation und genauere Kontrollen von Zöllen und Versandplänen, damit alles ohne unnötige Probleme abläuft.

Wildcrafted vs. kultivierte Zutaten

Wildcrafted-Zutaten wecken oft Interesse aufgrund ihres natürlichen Ursprungs. Dennoch stellen sie Umweltgefahren dar, es sei denn, verantwortungsvolle Beschaffung ist gewährleistet. Kultivierte Zutaten bringen Ordnung, bieten Teams stabile Erträge und Zeitpläne, die nicht abweichen. Die Wahl zwischen beiden hängt jedoch weiterhin davon ab. Sie müssen wissen, was das Produkt benötigt, wie wichtig natürliche Zutatenbeschaffung für Sie ist und ob die Auswirkungen der Landwirtschaft mit Ihren Nachhaltigkeitsverpflichtungen übereinstimmen.

Bio vs. konventionelle Beschaffung

Die Beschaffung von Bio-Zutaten zieht oft Käufer an, die sich dafür interessieren, wie Dinge angebaut werden, was in den Boden gelangt und ob der Prozess sowohl Menschen als auch Land respektiert. Konventionelle Optionen hingegen füllen weiterhin die meisten Lieferketten, da sie stabil, praktisch und das ganze Jahr über leicht verfügbar sind. Marken mischen oft beide, abhängig von Kosten, Verfügbarkeit und dem, was jede Formel wirklich benötigt.

Rohstoff- vs. Spezialzutaten

Rohstoffzutaten wirken wie der ruhige Teil der Beschaffung, bei dem Öle, Zucker und Salz pünktlich eintreffen und die Produktion am Laufen halten. Spezialzutaten bringen eine andere Dynamik. Adaptogene, fermentierte Extrakte und seltene Botanicals erfordern meist globale Zutatenbeschaffung, engere Zeitpläne und eine feste Koordination, insbesondere wenn Zertifizierungen, schwankende Verfügbarkeit und unvorhersehbare MOQs den endgültigen Plan auf unerwartete, aber handhabbare Weise beeinflussen.

Der Prozess der Zutatenbeschaffung (Schritt-für-Schritt)

Jedes Produkt beginnt mit einer Liste von Dingen, die Sie benötigen, auch wenn sich diese Liste später ändert. Beschaffung ist der Moment, in dem diese Ideen zu echten Zutaten werden, und deshalb verlangsamen Teams hier den Prozess. Dieser Schritt beeinflusst Qualität, Zeitpläne und Vertrauen, sodass Menschen ihn mit der Art von Aufmerksamkeit behandeln, die Probleme später verhindert.

1. Identifizierung von Zutatenanforderungen

Der erste Schritt besteht darin, die unverhandelbaren Anforderungen für Ihre Formel festzulegen, von den wesentlichen Bestandteilen bis zu den Zutaten, die Sie vermeiden möchten, sowie der Qualitätsgrenze. Es ist auch der Moment, in dem Sie entscheiden, ob das Projekt ethisch beschaffte Zutaten, natürliche Zutatenbeschaffung oder transparente Zutatenbeschaffung erfordert – nützlich, wenn Sie Zutaten aus einer gentechnisch veränderten Quelle vermeiden möchten.

2. Recherche potenzieller Lieferanten

Sobald die Anforderungen festgelegt sind, suchen Sie nach Großhandelslieferanten für Zutaten, die konsistent liefern können. Sie fragen nach Herkunft, Zertifizierungen, Testmethoden, Nachhaltigkeitsverpflichtungen und Kapazität. Viele Unternehmen vergleichen Profile durch innovative Beschaffungslösungen oder interne Datenbanken. Diese Phase prägt die Richtung der verantwortungsvollen Zutatenbeschaffung und hilft Ihnen zu entscheiden, mit wem sich ein tieferes Gespräch lohnt und wer nicht zu den langfristigen Zielen des Produkts passt.

3. Anfordern von Mustern & Dokumentation

Muster sagen viel aus: wie eine Zutat sich bewegt, riecht, mischt oder zerfällt. Die Unterlagen bestätigen dies. Teams überprüfen COAs, Allergenhinweise, Sicherheitsdatenblätter, mikrobiologische Tests, Herkunftsnachweise und Rückverfolgbarkeitsdokumente für Zutaten. Diese kleinen Dokumente tragen Gewicht, da sie die Qualitätssicherung von Lebensmitteln, die Klarheit der Zutaten und die verantwortungsvolle Beschaffung sowie Compliance-Prüfungen unterstützen, bevor etwas in eine vollständige Produktion aufgenommen wird.

4. Durchführung von Lieferantenaudits

Audits geben Ihnen einen klareren Überblick darüber, wie ein Lieferant Ihre Materialien handhabt. Sie überprüfen ethische Arbeitsbedingungen, saubere Praktiken, präventive Kontrollen, transparente Zutatenbeschaffungsprozesse und allgemeine Konsistenz. Einige Audits finden vor Ort statt, andere virtuell, wobei beide Probleme aufdecken, die Sie in E-Mails nie sehen würden. Dieser Schritt schützt Ihr Produkt, Ihren Zeitplan und Ihr Versprechen von ethisch beschafften Zutaten.

5. Vertragsverhandlungen

Nachdem die Tests und Audits solide erscheinen, geht es an die Bedingungen. Preise, Lieferzeiten, QC-Anforderungen, MOQs, Dokumentationserwartungen und Lieferpläne werden schriftlich festgehalten. Sie besprechen Details, die klein erscheinen, aber später wichtig sind, und setzen Grenzen für beide Seiten. Gute Verträge minimieren Überraschungen, stärken Lieferantenbeziehungen und unterstützen die globale Zutatenbeschaffung mit weniger Risiken.

Lokale vs Globale Zutatenbeschaffung

Lokale Beschaffung priorisiert nahegelegene Bauernhöfe für Frische, geringere Transportemissionen und Unterstützung der Gemeinschaft. Globale Beschaffung bietet Zugang zu vielfältigen, ganzjährigen Zutaten und wettbewerbsfähigen Preisen, erhöht jedoch die Umweltbelastung und die Komplexität der Lieferkette. Die Wahl zwischen beiden balanciert Nachhaltigkeit, Kosten, Verfügbarkeit und gewünschte Geschmacksprofile, oft durch eine Kombination beider Ansätze für optimale kulinarische und geschäftliche Ergebnisse.

Lokale Zutatenbeschaffung

Die lokale Zutatenbeschaffung hält Ihre Abläufe in Reichweite. Lieferungen kommen schneller an, die Logistik bleibt einfach und die Rückverfolgbarkeit bei der Zutatenbeschaffung verbessert sich. Teams schätzen die klarere Kommunikation, die Verbindung zu nahegelegenen Produzenten und den geringeren ökologischen Fußabdruck. Sie eignet sich für Marken, die auf Clean-Label-Zutaten, ethische Lebensmittelbeschaffung oder Projekte mit konsistenten, zugänglichen Lieferantenbeziehungen setzen.

Globale Zutatenbeschaffung

Die globale Zutatenbeschaffung kommt ins Spiel, wenn inländische Optionen nicht ausreichen, insbesondere bei botanischen Produkten, Extrakten, Mineralien oder anderen einzigartigen Materialien. Sie hilft bei der Kostenkontrolle, zuverlässiger Verfügbarkeit und breiteren Verarbeitungsoptionen. Viele Marken verlassen sich auf diesen Weg für eine stetige Versorgung und nachhaltig beschaffte Zutaten. Es ist praktisch, erfordert jedoch eine sorgfältige Handhabung von Dokumenten, Logistik und Beschaffungsstandards in verschiedenen Ländern.

Wichtige Faktoren bei der Auswahl von Zutatenlieferanten

Die Wahl eines Zutatenpartners bestimmt den gesamten Produktionsablauf. Einige Lieferanten machen es einfach, andere hingegen erschweren selbst die einfachsten Aufgaben. Ob es um die Beschaffung von Lebensmittelzutaten, Nahrungsergänzungszutaten oder Schönheitsproduktzutaten geht, das Ziel bleibt dasselbe: einen Partner zu finden, der transparent, zuverlässig und Ihren Qualitätsstandards entspricht – ohne Ausreden.

Qualitäts- & Sicherheitsstandards

Die Qualitätskontrolle bei der Beschaffung muss sehr klar und eindeutig sein. Die Lieferanten, die Sie benötigen, sind diejenigen, die sich der Tests, Dokumentation und Aspekte der Lebensmittelsicherheitsprüfung bewusst sind, ohne dass Sie sie daran erinnern müssen. Mikrobiologische Kontrollen, Pestizidüberwachung und Identitätsprüfung sollten zur Standardroutine gehören.

Falls ein Lieferant ausweichend ist, Ihnen keine Lösung bietet oder Sie mit Ihrer Papierarbeit verzögert, ist das meist ein Hinweis darauf, dass Sie einen anderen Lieferanten finden sollten. Zuverlässige Partner sorgen dafür, dass Ihr Produkt sicher ist, lange bevor es zu Ihnen gelangt.

Nachhaltigkeit & Umweltwirkung

Wählen Sie Lieferanten, die ihre Emissionen reduzieren, ressourceneffiziente Landwirtschaft betreiben und Zutaten verwenden, die von umweltfreundlich zertifizierten Unternehmen stammen. Einige von ihnen unterstützen sogar Biodiversitätsprogramme, was Ihnen zeigt, dass sie nicht nur reden, sondern tatsächlich weit in die Zukunft denken.

Der Unterschied zwischen ihnen wird sehr offensichtlich, wenn Sie sich diejenigen ansehen, die Nachhaltigkeit als ihre eigentliche Aufgabe behandeln, und diejenigen, die es nur erwähnen, wenn sie einen Verkauf tätigen möchten.

Ethische Arbeitspraktiken

Ethische Zutatenbeschaffung bezieht sich auf die Praxis, herauszufinden, wie Menschen am Ursprung behandelt werden. Faktoren wie faire Bezahlung, saubere und sichere Umgebungen sowie gute Arbeitszeiten sind gleichermaßen wichtig. Lieferanten, die ihren sozialen und ökologischen Verpflichtungen nachkommen, sind offen, bereit zu antworten und ziemlich entspannt, wenn sie ihre Praktiken teilen.

Es geht nicht darum, sie schlecht zu machen. Es ist einfach eine Frage der verantwortungsvollen Beschaffung von Zutaten und der Vermeidung unnötiger Risiken. Der Respekt gegenüber den Arbeitern führt zur Stabilisierung und macht die Lieferkette zuverlässiger.

Kosten & Logistik

Kosten umfassen viele Faktoren, nicht nur den Preis pro Einheit. Dazu gehören Versand, Zoll, Lagerung, Lieferzeiten und sogar unerwartete Verzögerungen, die sich alle auf Ihre Gewinnspanne auswirken. Hier werden effektive Strategien zur Rohstoffbeschaffung wirksam. Ein Lieferant, der Sie frühzeitig warnt, Probleme behebt und sich mit Ihnen weiterentwickelt, ist weitaus wertvoller als einer, der sich nur auf die Zahlen bezieht. Vertrauen wird Ihre Ausgaben mehr reduzieren als eine etwas günstigere Rechnung.

Rückverfolgbarkeit und Transparenz von Zutaten

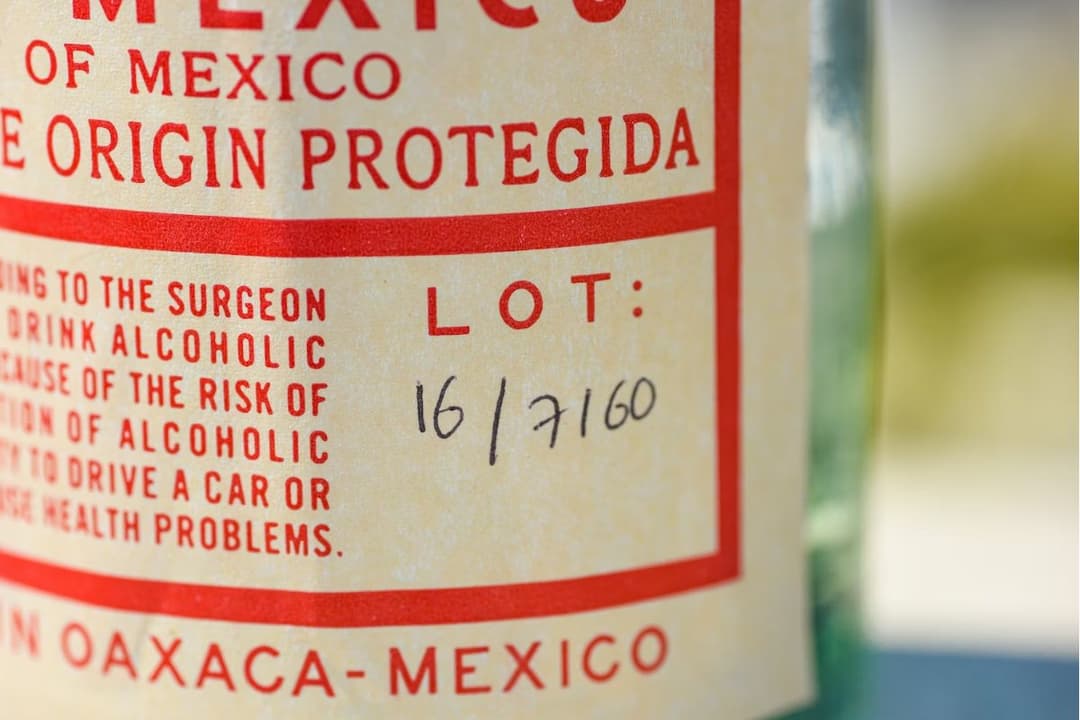

Die Rückverfolgbarkeit von Zutaten ermöglicht es Ihnen, genau zu verstehen, woher ein Material stammt, wie es verarbeitet wird und welche Personen es unterwegs handhaben. Obwohl es sehr einfach erscheint, ist es äußerst hilfreich, Marken vor Betrug zu schützen. Darüber hinaus ist es eine großartige Möglichkeit, Probleme mit Rückrufen daran zu hindern, sich auszuweiten. Kunden müssen darauf vertrauen können, was sie kaufen, und eine der einfachsten Möglichkeiten, dies zu erreichen, ist durch transparente Nachverfolgung, insbesondere wenn die Rezepturen von Zutaten abhängen, die aus verschiedenen Teilen der Welt bezogen werden.

Transparenz in der Lieferkette hängt von zahlreichen Systemen ab, die Chargennummern verfolgen, digitale Aufzeichnungen der neuesten Updates führen, das Verhalten von Lieferanten überwachen und denjenigen, die die Informationen benötigen, zugänglich machen. Es ist eine Art Arbeit, die man eher wahrnimmt, als sie direkt zu sehen. Und die Nachfrage steigt kontinuierlich, da Marken verpflichtet sind, die Herkunft ihrer Zutaten offenzulegen, sei es Kakao aus nachhaltigen Quellen, importierte Botanicals oder andere Materialien, die mit komplexen Beschaffungswegen verbunden sind.

Regulatorische Konformität bei der Beschaffung von Zutaten

Regeln können manchmal lästig sein, aber sie sind notwendig, wenn Sie Ihre Produkte sicher, legal und verkaufsbereit halten möchten. Jede Kategorie, sei es Lebensmittel, Kosmetik oder Nahrungsergänzungsmittel, hat ihre eigenen Regeln, und das Übergehen auch nur eines kleinen Teils kann später Probleme verursachen. Aus diesem Grund ist die Einhaltung von Vorschriften einer der ersten Schritte bei der Arbeit mit Zutaten.

Vorschriften in der Lebensmittelindustrie

Wenn Sie die Beschaffung von Zutaten für Lebensmittel und Getränke verwalten, müssen Sie die FDA-Richtlinien, FSMA-Vorschriften, Anforderungen an die Allergenkennzeichnung und GMO-Offenlegungen in Bezug auf Zutaten aus einer biotechnologisch hergestellten Quelle einhalten. Die Erstellung von Verfahren erleichtert die Audits und dient Marken als Schutzschild gegen Fehler, die einfach, aber leicht zu übersehen sind. Falls Sie Zutaten aus verschiedenen Teilen der Welt beziehen, verlassen Sie sich auf die richtigen Dokumente, um jedes Detail zu überprüfen.

Vorschriften für Kosmetik- und Körperpflegeprodukte

Die Beschaffung von Zutaten für Kosmetikprodukte ist mit eigenen Vorschriften verbunden. Die Sicherheitsbewertung, EU-Kosmetikverordnung, IFRA-Standard und Kontaminationsgrenzen sind Faktoren, die bestimmen, ob eine Zutat verwendet werden kann. Die Reinheits-, Stabilitäts- und Konzentrationswerte sollten innerhalb der genehmigten Grenzen liegen. Die hier beschriebenen zusätzlichen Schritte sorgen nicht nur dafür, dass sich die Verbraucher sicherer fühlen, sondern schützen auch die Endformel.

Nahrungsergänzungsmittel und Naturprodukte

Die Einhaltung der Vorschriften bei der Beschaffung von Zutaten für Nahrungsergänzungsmittel ist komplexer als in anderen Bereichen, da die Qualität von botanischen Zutaten je nach Herkunftsort sehr unterschiedlich ist. Die Einhaltung der DSHEA-Vorschriften, GMP-Erwartungen, Identitätstests und COA ist obligatorisch. Teams konzentrieren sich auf Wirksamkeit, Reinheit und Herkunftsbestätigung, insbesondere wenn die Zutat von ausländischen Lieferanten stammt. Ein einziges unklar dokumentiertes Papier kann den gesamten Prozess stoppen, daher ist Präzision von Anfang an wichtig.

Nachhaltige und ethische Strategien zur Beschaffung von Zutaten

Nachhaltige und ethische Beschaffung ist eine Praxis, die Marken anwenden, um nicht nur ihre Produkte, sondern auch ihre Lieferanten und ihren guten Ruf auf dem Markt zu bewahren. Einige Unternehmen leisten enorme Anstrengungen, während andere zunächst kleine Schritte unternehmen. In jedem Fall ist Nachhaltigkeit in der gesamten Lieferkette involviert, und Sie werden sehen, wie diese Strategien verwendet werden, um ethische Lebensmittelbeschaffung, Zutaten-Transparenz und verantwortungsbewusste Beschaffungsentscheidungen zu unterstützen.

Zertifizierungen, auf die Sie achten sollten

Zertifizierungen helfen dabei, zu bestätigen, dass ein Lieferant, der eine Behauptung aufstellt, diese auch mit Maßnahmen untermauert. Auch wenn sie nicht perfekt sind, dienen sie dennoch als wichtige Indikatoren bei der Auswahl von Partnern. Deshalb sehen Sie viele Zertifikate wie:

- USDA Organic

- Fair Trade

- RSPO

- Rainforest Alliance

- Non-GMO Project

- COSMOS oder ECOCERT für Kosmetik

Das Vorhandensein der vorgenannten Labels ermutigt Kunden, dem, was sie kaufen, bereitwillig zu vertrauen, und bietet gleichzeitig eine Plattform für Unternehmen, die ihre Verantwortung ernst nehmen.

Ein nachhaltiges Beschaffungsprogramm aufbauen

Personen mit einer langfristigen Perspektive auf nachhaltige Zutatenbeschaffung werden mächtiger, wenn ihre Teams loyal sind. Die Mehrheit der Marken entwickelt Programme, die Folgendes betonen:

- Reduzierung des CO2-Fußabdrucks

- Bildung und Unterstützung für Landwirte

- Investitionen in nachvollziehbare Systeme

- Zusammenarbeit mit Lieferanten, die Nachhaltigkeit zu ihrem Ziel gemacht haben

- Definition von KPIs, die das Programm wachsen lassen

So tragen diese Maßnahmen zu einem zuverlässigen, ehrlichen und transparenten Herstellungsprozess bei der Beschaffung von Zutaten bei.

Vermeidung kontroverser Zutaten

Einige Zutaten sind mit verschiedenen Problemen verbunden, und Unternehmen bemühen sich, keine Substanzen zu verwenden, die mit umweltschädlichen Praktiken in Verbindung stehen. Einige der Probleme, die normalerweise mit solchen Zutaten einhergehen, sind:

- Verlust von Waldlebensräumen

- Zwangsarbeit

- Übermäßiger Einsatz von Chemikalien

- Verschmutzung natürlicher Ressourcen

Indem sie diese Arten von Gefahren vermeiden, fördern Unternehmen Zutaten-Transparenz und verantwortungsbewusste Beschaffung und stellen so sicher, dass es im Produkt nichts gibt, das den Werten der Kunden widerspricht.

Checkliste für die Beschaffung von Zutaten

Jedes Team benötigt eine Checkliste, auch wenn die Teammitglieder mit dem Prozess sehr vertraut sind. Eine Checkliste unterstützt den Prozess und bewahrt Sie davor, Details zu vergessen, von denen Sie dachten, dass Sie sich daran erinnern würden. Einige Punkte auf der Liste können schnell überprüft werden, während andere eine gründliche Betrachtung erfordern. Tatsächlich helfen sie Ihnen, organisiert zu bleiben, Überraschungen zu vermeiden und die Beschaffung von Zutaten für Lebensmittel, Kosmetik und Nahrungsergänzungsmittel auf dem erwarteten Niveau zu halten.

Eine effektive Checkliste umfasst normalerweise:

✅ Detaillierte Spezifikationen, die die Eigenschaften definieren, die die Zutat haben sollte

✅ Maßnahmen zur Lieferantenbewertung, die anzeigen, wer vertrauenswürdig ist und wer nicht

✅ Anforderungen an Dokumentationen, die Qualität und Compliance sicherstellen

✅ Umweltfreundliche Kriterien, die die Erwartungen an Lieferanten widerspiegeln

✅ Rückverfolgbarkeitsaufzeichnungen für eine ordentliche und transparente Zutatenbeschaffung

✅ Risikobewertungen, insbesondere für die globale Zutatenbeschaffung

✅ Eine Preis- und Logistikprüfung, die sich auf die alltäglichen Aspekte konzentriert

✅ Notfallpläne, da Dinge nicht immer wie geplant verlaufen

Teams können diese Liste verwenden, um konsistent zu bleiben, blinde Flecken zu vermeiden und ihre Entscheidungsfindung fundiert zu halten.

Herausforderungen bei der Beschaffung von Zutaten

Die Beschaffung von Zutaten ist nicht weniger als ein Puzzle mit seinen beweglichen Teilen, sich ändernden Bedürfnissen und herausfordernden Ereignissen. Egal in welcher Branche Sie tätig sind, Unternehmen müssen gut kommunizieren, regelmäßig planen und ein vertrauenswürdiges System für die Rückverfolgbarkeit von Zutaten haben, wenn sie die Arbeit am Laufen halten wollen.

Verfälschung & Kontamination

Der Grund, warum die Mehrheit der botanischen Produkte, Gewürze und Öle riskanter ist, liegt darin, dass sie mehr Zwischenstationen durchlaufen, bevor sie die Verarbeitungsanlage erreichen. Während einige Materialien in einem sauberen Zustand geliefert werden, erfordern andere gründliche Tests. Kontinuierliche Überprüfung, eindeutige Bereitstellung und Rückverfolgbarkeit ermöglichen es Ihnen, Probleme in ihrem Anfangsstadium zu erkennen. Wenn Sie solche Systeme nicht haben, ist es leicht, kleine Details zu übersehen, die schließlich zu größeren und kostspieligeren Problemen werden.

Betrug in der Lieferkette

Betrug lauert normalerweise in den weniger sichtbaren Teilen der Beschaffung. Um ihre Gewinne zu steigern, könnte ein Lieferant Materialien mischen, die Herkunftsgeschichte erfinden oder kostengünstigere Methoden ohne Ihr Wissen verwenden. Transparente Herstellungsprozesse bei der Beschaffung von Zutaten helfen, diese Arten von Inkonsistenzen aufzudecken. Wenn Dokumente nicht übereinstimmen oder die Details „verdächtig“ erscheinen, ist dies meist ein Signal, dass Sie alles noch einmal überprüfen müssen.

Saisonale Knappheit

Verschiedene landwirtschaftliche Zutaten erfordern Timing, Wetter und Glück, um erfolgreich zu sein. Es gibt Jahre, in denen die Produktion sehr hoch ist, und andere, in denen sie gerade ausreicht, um die Nachfrage zu decken. Probleme mit dem Klima, Stürmen und unerwarteten Umweltveränderungen können die Versorgung ohne Vorwarnung sehr niedrig machen. Die Teams, die die Trends der globalen Zutatenbeschaffung im Auge behalten, reagieren in der Regel schneller, während diejenigen, die langsamer handeln, oft Schwierigkeiten haben, die verlorene Zeit wieder aufzuholen.

Marktpreisvolatilität

Die Preise für Zutaten bleiben selten stabil. Sie schwanken mit der Nachfrage, Versandverzögerungen, globalen Konflikten und der Knappheit bestimmter Rohstoffe. Informiert zu bleiben über Lieferanten und lokale Trends macht diese Schwankungen weniger schmerzhaft. Die Teams, die diese Veränderungen frühzeitig beobachten, treffen meist stärkere und zuverlässigere Beschaffungsentscheidungen.

Kostenmanagement bei der Beschaffung von Zutaten

Kostenkontrolle bei der Beschaffung betrifft nicht nur die eingesparten Gelder, sondern auch die Stabilität des Unternehmens. Während einige Preise stetig steigen, können andere dramatisch und plötzlich ansteigen, und Lieferanten könnten in ihrer Lieferfähigkeit eingeschränkt werden. Ein geeignetes System ermöglicht es den Teams, Notfallpläne zu haben und vorbereitet zu bleiben.

Preisprognosen

Preisprognosen sind weiterhin unsicher; sie bieten jedoch einige Hinweise auf die zukünftige Entwicklung in diesem Bereich. Teams analysieren Marktdaten, landwirtschaftliche Trends und historische Preise, um die ersten Anzeichen von Veränderungen zu erkennen. Es ist wie ein Wettercheck, bevor man hinausgeht. Wenn Marken bei der Beschaffung ihrer Zutaten auf globale Quellen angewiesen sind, werden sie regelmäßig von Maklern, Erzeugern und regionalen Partnern informiert, damit sie nicht unter den Folgen von Unvorbereitetheit leiden müssen.

Verhandlungsstrategien

Verhandlungen umfassen viele Aspekte neben dem Preis, und eine ruhige Vorgehensweise ist weiterhin effektiv. Die Mehrheit der Teams definiert Zahlungsbedingungen, Mindestbestellmengen, Flexibilität bei Lieferzeiten sowie mögliche Vereinbarungen über Festpreise. Mengenrabatte werden ebenfalls häufig erwähnt. Solche Gespräche helfen beiden Parteien herauszufinden, was möglich ist, was verboten ist und welche Änderungen die Beziehung ohne unnötige Reibungen langfristig machen.

Verwaltung von Mindestbestellmengen

Mindest bestellmengen (MOQs) können einschränkend erscheinen, wenn der verfügbare Lagerraum, die Nachfrage und die Produktlebensdauer nicht kompatibel sind. Lieferanten legen MOQs basierend auf ihrer Produktionskapazität fest, und Marken bewerten diese Zahlen im Vergleich zum tatsächlichen Verbrauch im Geschäft. Sie analysieren die Umschlaghäufigkeit der Zutat, ihre Haltbarkeit und den verfügbaren Platz im Lager. Einen Kompromiss zu finden, ist das Wesentliche.

Großeinkäufe

Der Einkauf in großen Mengen kann sich für solche Zutaten als vorteilhaft erweisen, da sie stabil und vorhersehbar sind, aber dennoch keine universelle Strategie darstellen. Es erfordert Platz, Planung und die richtige Art von Cashflow. In einigen Fällen wird der Großeinkauf als Mittel zur Sicherung besserer Preise angesehen. In anderen wird er vermieden, da das Lagern zu vieler Bestände problematisch werden könnte. Die Kunst liegt darin, den Punkt zu kennen, an dem der Kompromiss funktioniert.

Fazit

Woher die Zutaten bezogen werden, bestimmt nicht nur die Funktionalität des Produkts. Es beeinflusst auch die Wahrnehmung der Kunden gegenüber dem Produkt und die reibungslosen Abläufe hinter den Kulissen. Die Entscheidungen des Lieferanten, Rückverfolgbarkeit, Nachhaltigkeit und Kostenmanagement basieren aufeinander. Es geht nicht nur darum, Materialien zu finden, die den Spezifikationen entsprechen, sondern auch darum, Beziehungen aufzubauen, die bestehen bleiben, wenn Märkte angespannt sind oder sich die Nachfrage ändert. Wenn Teams ihre Standards klar definieren, halten sie die Kommunikation offen und überprüfen jeden Schritt. Sie verfügen über ein Beschaffungssystem, das sie bei ihrem Wachstum begleiten kann. Eine gute Zutatenbeschaffung ist keine einmalige Errungenschaft. Es ist eine kontinuierliche Routine, die die Qualität, Transparenz und Beständigkeit einer Marke sicherstellt.

Anfrage für Großbestellung

Einfache Bestellung, transparente Preise, direkt an Ihre Tür geliefert