Supply Chain Planning: Examples, Process, KPIs

Learn the ropes of supply chain planning with examples, processes, KPIs, tools, and strategies to improve forecasting, resilience, and performance.

200+ compradores confían en Torg para el sourcing

Every product you touch has taken a long, winding journey before it reaches you. Some trips run smoothly. Others hit delays, detours, and last-minute scrambles. That is where supply chain planning steps in. It connects decisions, timing, people, and data, so operations do not feel like a daily fire drill. When plans are clear, teams move with confidence. When they are not, confusion spreads fast, and costs quietly climb. So, how do businesses keep everything in sync while markets shift, orders spike, and suppliers change pace? The guide examines actual planning examples, effective methodologies, and significant KPIs. You will also see how careful planning can help a business grow, stabilize the operations, and keep the customers happy, even in uncertain times with a high level of stress.

What Is Supply Chain Planning?

Supply chain planning is the first stage of the product lifecycle before the product is delivered to the shelf or loading dock. It begins in meeting rooms, on shared spreadsheets, and forecasting software, where the staff attempts to synchronize demand, supply, and capacity without causing problems downstream.

In supply chain planning, one decision nudges another. Procurement timelines affect production runs. Factory output shapes warehouse capacity. Transport limits influence delivery promises. Along the way, predictive analytics in supply chain help identify risks at an early stage while experience complements the areas that data are not able to cover.

However, hardly any plans stay still. Market fluctuations, supplier delays, and unexpected order surges require continuous adjustment. Value chain analysis is the tool that helps here, identifying the impact of each operational change on cost, speed, and margin. When planning holds together, coordination feels steady and controlled. When it slips, small errors compound quickly, and operational pressure spreads across teams, partners, and leadership alike.

Supply Chain Planning Examples

It is a lot easier to understand what's involved in planning if you look at how large companies cope with real pressure. Different industries have their own set of risks, timelines, and limitations but the goal remains the same: keep the operations running, be able to respond to the changes, and keep the costs under control. In fact, one can see the similarity in patterns across fast fashion, food, electronics, and healthcare sectors.

Some rely on speed. Others depend on precision. A few lean heavily on resilience. What does good planning look like when the stakes are high? Below are some of the real-world examples of how top brands convert strategy into everyday practice.

Apparel – Zara (Inditex Group)

Zara has established its name in the market for its speedy response and tight control over production cycles. The planning model of the company facilitates new designs to be available from concept to store shelves in the matter of weeks, which is supported by a highly integrated supply chain that links designers, factories, and retail data in near real time. The method lowers the markdown risk and also supports end to end supply chain planning, hence, seasonally varying demand is not a problem.

Rather than committing to huge production runs, Zara allows volume to remain flexible, and then it modulates output according to sales signals at the store level. That cadence enables the company to hold minimal stock and at the same time be agile to changing fashion trends.

Food Distribution – Walmart

In an effort to increase the speed of grocery flows, decrease waste, and enhance the accuracy of forecasting, Walmart remains committed to the significant investment in automated distribution centers. They are leveraging automation for improved planning accuracy and operational stability while their new temperature-controlled facilities are focused on accelerating the movement of perishables.

These enhancements give planners the flexibility to change routes, replenishment cycles, and stock levels on a daily basis, contributing to the freshness, running less spoilage, and having a more predictable cost structure of thousands of retail locations.

Electronics – Apple

One of Apple's pioneering supply chain features is the flawless integration of product design, supplier management, and logistics execution. Apple continues to be able to offer its products rapidly across the globe by maintaining a consistent level of production through the optimization of its supply chain network and forming long-term partnerships with its suppliers.

The emphasis is on precision in the planning process at this point. If the three elements, component sourcing, manufacturing schedules, and distribution timing, are not seasonably adjusted to each other, then the delays get propagated very quickly throughout the entire market.

Healthcare – Mayo Clinic

To oversee medical supplies, freight movement, and hospital inventory, Mayo Clinic created integrated logistics and planning systems. The method not only increases the precision of the forecasts but also makes the whole process visible and helps the fast reaction during the times of high demand.

It is not only a question of margins that planning in healthcare deals with. Rather, it is a question of trust, the safety of patients, and the coordination of the whole system which is especially critical during volume spikes or when emergencies occur.

Key Elements of Supply Chain Planning

At the heart of every effective planning system, there is a small set of fundamental components. Each of them has a different function, but they can only operate if they coordinate.

1. Demand Planning

Demand planning is the one that determines the pace for all other operations. Teams analyze the sales trends, changes in customer behavior, promotional effectiveness, and market dynamics, then they combine these signals with the real world context.

Demand planning along with the chosen demand forecasting methods enable the forecasts to be flexible. This makes it possible to respond quicker, have a better focus, and work together more efficiently across different departments. Also, the cost of unpleasant surprises which occur when demand suddenly changes is lowered.

2. Supply Planning

Once demand takes shape, supply planning decides how that volume becomes reality. Supplier lead times, factory limits, and shipping constraints guide each choice. With advanced supply chain planning models, teams test scenarios, weigh trade-offs, and stay flexible.

This helps protect service levels, manage costs, and maintain steady flow, even when unexpected disruptions push original assumptions off track.

3. Production Planning

Production planning translates forecasts into workable factory schedules. It corresponds to the production output levels, shift patterns, and equipment utilization, at the same time it considers the availability of labor and materials.

If the production is in line with the overall supply chain planning objectives, production is evenly balanced, congestion is avoided, and delivery commitments are protected. This close coordination leads to less machine stop times, less errors and production remains unchanged, even in the case of sudden demand or supply problems.

4. Inventory Management

Inventory planning is the main element that connects service and cash flow. Keen inventory management strategies that smartly govern stocks aim to have only as much as needed to fulfill the customer's demand without locking capital.

Being aware of inventory turnover rates helps you identify slow moving products and discover hidden surplus. This trade-off continuously leads to less waste, more working capital availability, and improved flexibility when the ordering volume suddenly increases or the product mix changes.

5. Distribution & Logistics

To plan distribution is to make certain that the products get to where they are supposed to be without unnecessary delay or extra cost.

By means of logistics and supply chain planning, the teams figure out how to make the best use of routes, warehouse locations, and transportation options. Time is of the essence. Coordination is as valuable. Where there is an efficient distribution, there is an increase in the level of service along with the stabilization of costs and the easier handling of supply chain disruptions even when external factors such as weather, traffic jam, or fuel prices change.

6. Sales and Operations Planning (S&OP)

Sales and operations planning is the actual link that connects commercial targets with the operational reality. So by aligning the forecasts, budgets, and capacity plans, S&OP ensures smoother execution. It enhances communication, uncovers risks at an early stage, and promotes shared responsibility.

As a result of this alignment, the speed of decision making is increased, interdepartmental trust is developed, and the long-term objectives become more consistent with the operational limits of the daily work.

Why Is Supply Chain Planning Important?

Behind every smooth operation sits a planning framework that keeps people, systems, and decisions aligned. When that framework works, progress feels steady. When it slips, friction shows up fast. Supply chain planning gives teams a way to stay grounded, move with purpose, and respond without panic, even when conditions change without warning.

Operational Stability

Operations run best when surprises stay small. Intent, thoughtful planning introduces order into the daily work cycles of a team so that the team members anticipate changes and know how to react to them. Disruptions with well-defined supply routes, flexible schedules, and adjusted logistics become controllable rather than overwhelming, thus the output remains constant and stress limited.

Cost Efficiency

Every extra mile, rushed shipment, and excess pallet carries a hidden cost. Efficiency planning helps in reducing the unnecessary waste of time by way of better timing, balancing of load, and placing of inventory because these minor savings accumulate over time. The firm would become more cost-effective in procurement and the production process would be more consistent while warehousing would be more efficient. That way, more resources will be available for those areas to flow and support long-term returns.

Customer Satisfaction

Reliability shapes trust. When planning is a real reflection of capacity, deliveries happen as scheduled, communication stays clear, and service is consistent. That regular pace creates trust with both partners and customers, which leads to orders coming in again, contracts being longer, and relationships becoming stronger, even if market conditions change or competition is at the door.

Risk Reduction

Uncertainty is always there, but preparation makes a different feeling of it. A good supply chain risk management plan shows the weaknesses, tests the response paths, and reduces the time of the recovery. Rather than responding late, the teams act early, continuing the operation, keeping the money coming, and maintaining the reputation in case of sudden supply disruptions or demand increases.

Strategic Growth

Growth adds layers of complexity. New markets, new suppliers, and higher volumes demand stronger coordination. Through disciplined planning and control, expansion stays balanced. Investments align with capacity, networks scale with purpose, and operations remain stable, supporting confident decisions that push the business forward without stretching it too thin.

The Supply Chain Planning Process

Every planning cycle follows a certain rhythm. First, there are the incoming signals. Then the patterns that were formed help the decision making. After that, execution starts and the cycle goes on. This process not only keeps demand planning, supply planning, and inventory planning on the same page but it also allows teams to make changes when the situation is changing.

Demand Signal Collection

Demand signals are sourced from sales data, digital channels, field teams, and distributor feedback, after which demand signal collection structured models. This initial phase is helpful to remove the demand planning noise, identify the patterns, and make the demanforecasts more realistic. Now, if the inputs are kept clean and consistent, planning decisions will have clarity, direction, and confidence, even if there are market movements that are not predictable.

Forecast Development

During the forecast development phase, planners use various highly advanced models, past trends, and business insight to come up with realistic expectations. Testing different scenarios allows measuring the impact of promotions, changes in prices, and seasonal changes. Striking this a careful balance not only enhances the demand forecasting methods but also gets the teams ready to respond quickly when new signals challenge the earlier assumptions or disrupt the planned outcomes.

Supply Matching

Supply matching makes forecasts become real plans and actions. Manufacturing restrictions, vendor lead times, and shipping capacities lead the decision of distributing the resources. By jointly planning supply, companies achieve a compromise between meeting the customers and controlling the expenses, guaranteeing that materials, workforce, and transportation are constantly in agreement. This phase is a way of safeguarding the continuity of operations under the different conditions of supplies by precluding stockouts, excessive commitments, and overreaction.

Inventory Allocation

Inventory allocation is the process of distributing stock among different locations to fulfill the demand efficiently without overstocking. Intelligent inventory planning takes into account factors such as product turnover, service level goals, and delivery time. By bringing goods nearer to customers and, at the same time, limiting storage requirements, companies become more responsive, decrease their waste, and maintain their working capital at a level that allows them to grow, invest, and be operationally resilient.

Execution Monitoring

Execution monitoring is the tool that keeps the plans attached to real events. Real time dashboards enhance the overall supply chain visibility, showing where there are delays, bottlenecks, and shifts in priorities. Teams react rapidly, work out new schedules, and change routing flows. The perpetuation of this feedback loop allows quicker decision making, more consistent operations and better coordination between teams in logistics, production, and those dealing with customers.

How to Design a Supply Chain Planning System

You start designing a planning system by first having clarity and then going through the steps of structure, technology, and team. Each step is a continuation of the last one, thus, together, they shape a framework that facilitates the daily decisions and long, term goals of the company in a very simple and efficient manner

Define Planning Objectives

Every system begins with purpose. Defining supply chain planning objectives very clearly helps in directing the activities. They can be about faster delivery, stricter cost control, better service levels, or stronger resilience. The priorities thus become the blueprint for design elements, team victories, and the whole atmosphere, ultimately helping the teams stay in sync while they weigh up the factors of growth, risk, and operational performance across the entire network.

Map Network Structure

Mapping a network uncovers the paths of materials, information, and decisions along the suppliers, factories, warehouses, and customers. It serves to make supply chain dependencies, to point out bottlenecks, and to help the supply chain network design be more efficient. Once the flows are made visible, not only does resource allocation become more efficient but also lead times become shorter, planning assumptions become more accurate even though complexity increases with the scale.

Choose Planning Technologies

Picking the right platforms enables forecasting to run smoothly, makes supply chain planning tools more effective, and unites teams via shared data. When transparency is increased, decisions are made quicker, mistakes are fewer, and human labor decreases, thus planners are given room to concentrate on analysis, collaboration, and strategy.

Build Collaborative Workflows

A company will be successful only when its employees are performing as a team. Collaborative planning in supply chain environment involves shared ownership, open communication, and aligned priorities. When an organization connects sales, operations, finance, and partners via common processes, it is likely to reduce friction, speed up decision cycles, and develop planning routines that change naturally with changing conditions.

Best Supply Chain Planning Strategies

Good supply chain planning strategies serve as a robust framework of guidelines to ensure that the business is well-prepared through the different phases of a chain. Here are 5 planning strategies for you to consider:

Demand Driven Models

In a demand driven supply chain, planning starts with paying a great deal of attention to the actual customer's orders, market changes, and customer behavior. Then these signals form the basis for production and sourcing decisions.

As forecasts are updated more frequently, inventory remains lean, lead times are reduced, and service gets better, which means businesses are more in sync with demand rather than reacting late to changing customer expectations.

Agile Network Design

Agile supply chain strategies must rely on flexible structures rather than fixed mechanisms by functional departments. Some of the measures that a company can take here include flexible sourcing, modular production, and responsive logistics. These three aspects give a team the ability to quickly change the direction in case of an unexpected event.

When the market changes, agility hardly ever gets discontinued, rather it helps to stabilize output, and in most cases, the quick rebalancing of the whole system is a natural consequence that assures that operations are kept efficient rather than being frozen by the old supply and demand patterns.

Integrated Decision Making

Integrated supply chain planning links commercial goals with operational realities through the sharing of data and cross, functional alignment. Production choices are informed by sales signals. Delivery commitments are shaped by logistics feedback.

This continual communication lessens friction, speeds up the reaction time, and strengthens the consistency, allowing companies to stay ahead rather than going off in separate, competitive directions.

Sustainability Focus

Supply chain decisions that take into account sustainability continue to be influenced by the choices of sourcing, transport, and packaging while still meeting performance goals. Eco-friendly paths, fair trade suppliers, and waste reduction raise the level of compliance and resilience of the company.

Gradually, decisions like these help to deepen the relationships with the partners, lead to the support of regulations, and increase the trust of the consumers in the brand. Especially since environmental responsibility is becoming a major factor of competitiveness in the future.

Continuous Optimization

Teams use supply chain optimization techniques to analyze performance, change their assumptions, and optimize their processes. Implementing small changes bit by bit makes the operations more efficient, ensures the continuation of service levels, and increases the ability to respond to customers.

Such gradual improvement results in increased dynamics and so it becomes natural for the companies to be flexible when their volumes increase, new technologies become available, and the market conditions change.

Supply Chain Planning Tools & Software

Tech is the driver that turns planning decisions into daily action. Having the right systems in place not only helps to simplify complexity but also to connect data and enable teams to respond more quickly when the conditions change. At the heart of the digital backbone of modern planning environments are these core tools.

Forecasting Platforms

Forecasting platforms combine historical data, market movements, and real time signals to create precise demand planning. These systems alleviate the burden of calculations and regularly update projections, reducing uncertainty, closer responsiveness, and facilitating planners to foresee changes ahead of their impact on production schedules, inventory positioning, and supplier coordination.

Planning Suites

An extensive range of planning suites unify demand forecasting, inventory planning, production and materials control plus logistics flows into one common system. The best supply chain planning software is the backbone of interdepartmental connection, the facilitator of better coordination, and the supporter of quicker trade-off decisions, so the teams can manage cuts in capacity, changes in stock levels and delivery timing without creating operational bottlenecks.

Execution Management Systems

Execution management software transforms strategic plans into concrete actions by monitoring orders, shipments, and warehouse operations. Immediate updates indicate its points stressed in detail, deviations, and productions overloaded so the team can react to the changed itineraries, postponed tasks, and running the operations smoothly without necessarily giving up a dilemma that happens unexpectedly and threaten delivery commitment.

Analytics Dashboards

Analytics dashboards transform raw data to meaningful summary through supply chain analytics and shared performance metrics. Data visualization supports a quicker decision making process, uncovers the potential risks of the future, and fosters a sense of responsibility, helping leaders and planners to be on the same page about the progress, priorities, and the areas that need immediate measures.

Challenges in Supply Chain Planning

Though plans might be perfect, they always face some kind of friction. The shortage of data, the variations of the markets, the limitations of the systems always put tests in supply chain operations on a daily basis. Knowing the places where planning fails is the key to the teams being able to recognize the problem at an early stage, get to the point quickly, and ensure the stability of even a complicated supply network.

Data Quality Issues

Planning relies heavily on dependable data; however, disjointed systems, tardy reports, and inconsistent records have been impeding forecasting. Poor quality of data not only causes misunderstanding but also delays decision making and weakens trust. In the absence of clean and integrated data, thoroughly planned models, no matter how good, would find it difficult to accurately and consistently direct sourcing, production, and distribution.

Supplier Variability

Uncertain situations are created by fluctuating lead times, changing costs, and inconsistent delivery performance. Poor supplier relationship management increases these risks further by limiting the two elements it is based on: visibility and trust. Whereas, solid partnerships enhance communication, make the supply more predictable, and lower the probability of sudden supply disruptions that cause delays not only in production but also in the fulfillment schedules.

Market Volatility

Demand can swing overnight due to trends, promotions, or external shocks. These rapid changes strain forecasts and challenge static planning models. To deal with such situations, companies require adaptable procedures, efficient instruments, and quick feedback cycles that enable them to make changes before the imbalance gets transmitted through inventory, capacity, and distribution networks.

Capacity Constraints

Limited production slots, labor shortages, and transport bottlenecks restrict responsiveness during demand surges. Without a well-thought-out supply chain implementation plan, these restrictions result in delays and costs increase. Proper capacity planning, flexible scheduling, and having a backup plan can help the continuance of the flow even when the volume suddenly goes beyond the operating comfort zones.

Technology Integration

Disconnected systems slow information flow and blur accountability. When planning tools, execution platforms, and reporting systems fail to align, decisions arrive late. A perfectly integrated business planning not only helps fill these gaps but also leads to a greater shared understanding, better coordination, and quicker responses among sales, operations, finance, and logistics departments.

Supply Chain Planning KPIs and Metrics

KPIs serve as clear signals from daily operations. They indicate which areas are performing well, which need improvement, and where changes will have the greatest impact. If supply chain performance metrics are monitored regularly, they can help in continuous progress, making more informed trade-offs, and achieving a better fit between planning, implementation, and long term business objectives.

Forecast Accuracy

Forecast accuracy calculates the degree to which forecasted demand aligns with actual sales by the formula:

Forecast Accuracy = (1 - |Forecast - Actual| ÷ Actual) × 100

Forecast accuracy at a higher level enhances the reliability of planning, lowers inventory surplus, increases the level of service, and facilitates quicker response of the teams to the changes in customer patterns and market behavior.

Order Fulfillment Rate

Order fulfillment rate is the metric that measures the percentage of orders that are delivered in full and on time and is calculated using the formula:

Order Fulfillment Rate= Orders delivered in full ÷ total orders × 100

Healthy results indicate good teamwork between planning, inventory, and logistics. On the contrary, poor results point to the problems that rejection of delivery promises, loss of customer trust, and general operational instability are symptoms of.

Inventory Turnover

Inventory turnover demonstrates the pace at which stock moves through the system by applying this formula:

Inventory Turnover = Cost of goods sold ÷ average inventory

A higher turnover indicates that the inventory is flowing efficiently which means less cost of keeping goods and a better cash cycle. On the other hand, a lower turnover reveals that the stock is not moving quickly, thus the capital is tied up, and there is a misalignment in planning.

Lead Time

Lead time is the amount of time it takes to complete an order after it has been confirmed until it gets delivered. The shorter lead times are beneficial to the company as they increase the company's ability to respond to changes in the market, planning accuracy is improved, and the company is able to make reliable commitments to its customers.

On the contrary, lengthier lead times usually reveal the existence of bottlenecks, supplier problems, or the delivery of goods through inefficient routes, in other words, the network's logistics inefficiency.

Sustainability Performance

Sustainable performance tracking is a great lever for sustainable supply chain practices. It basically monitors carbon footprint, usage of energy, waste reduction, and supplier ethics among others. Such indicators lead to more efficient transportation, choice of suppliers, and packaging materials, at the same time, they help to maintain compliance, enhance brand image, and ensure business continuity even in highly regulated markets.

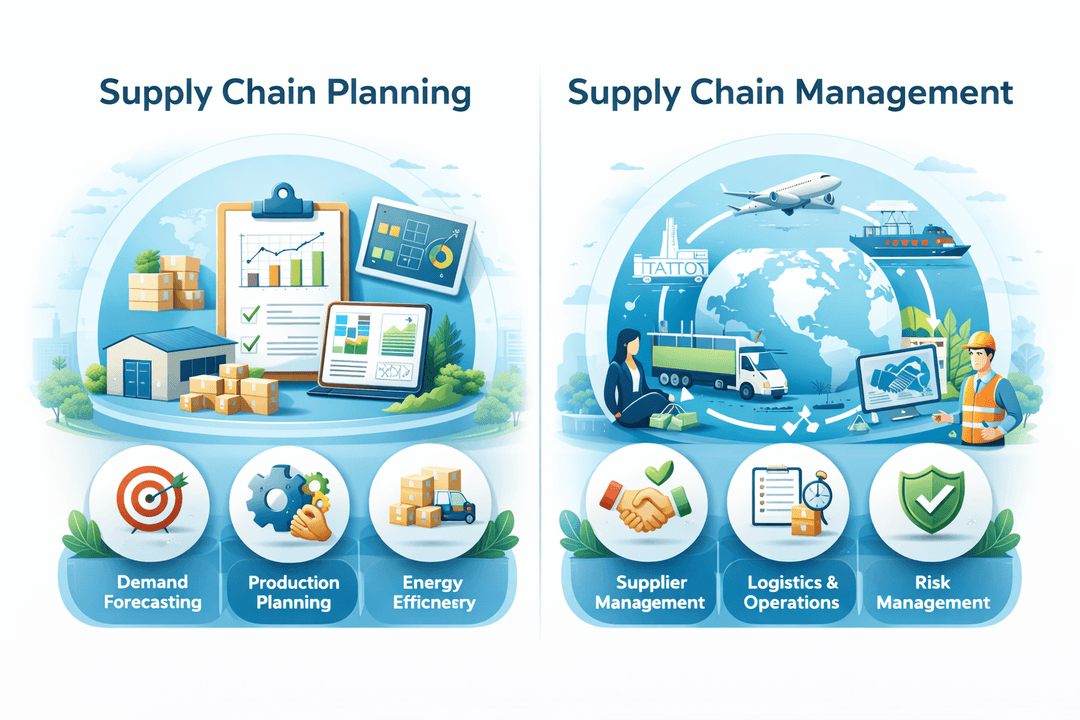

Supply Chain Planning vs. Supply Chain Management

At first glance, planning and management may sound interchangeable, yet they serve very different purposes. Supply chain planning designs the path forward, while supply chain management makes sure every step lands where it should. Together, they keep operations steady, focused, and ready for change. When aligned, teams move with confidence. When disconnected, confusion creeps in, and momentum fades.

Supply Chain Planning

Supply chain planning is all about making decisions now that will shape the future. Teams predict demand, run different scenarios, and figure out how to balance supply with their capacity so that they feel less uncertain for the next day. Among the tools to be mentioned is the supply chain demand planning software that assists in the transformation of raw data into genuine insights, enabling planners to discover changes, modify the schedules, and maintain the service level before any problem occurs.

This kind of planning role allows organizations to have a little bit of breathing space. It assists leaders to raise questions like, What if? and gives them answers based on clear, well-supported data rather than impulses or instincts.

Supply Chain Management

Supply chain management is responsible for the day to day operations that keep everything moving smoothly. It is a process that organizes the dispatch of goods, controls warehousing operations, keeps in touch with suppliers, and solves the problems that arise on a daily basis.

Timing is a crucial factor. So is the quality of the product. Managers work to keep things running, avoid interruptions, and be in the best situation to give out the services. Their method is very close to the ground based on what is happening at the moment and is influenced by regular changes.

Whereas planning is setting the stage, management is making sure the play goes on as expected in the areas of sourcing, manufacturing, storage, and distribution.

Difference Between Supply Chain Planning and Supply Chain Management

Aspect | Supply Chain Planning | Supply Chain Management |

|---|---|---|

Core Focus | Future decisions and preparation | Daily execution and control |

Time Horizon | Medium to long term | Short term and real time |

Primary Goals | Forecast accuracy, resource allocation, scenario modeling | Order fulfillment, operational stability, service reliability |

Key Activities | Demand forecasting, capacity planning, network design | Shipment coordination, warehouse operations, supplier communication |

Main Tools | Forecasting systems, planning platforms, analytics models | Execution systems, transport management, warehouse systems |

Decision Style | Strategic and analytical | Tactical and operational |

Risk Approach | Anticipates and prepares for disruptions | Responds and recovers from disruptions |

What Is In a Supply Chain Plan?

A supply chain plan acts like a working playbook. It is not stored on a shelf. It remains open, is frequently updated, and directs the daily decisions. The goal is very clear: to maintain the business operations stable and to have a preparedness for any changes. Here are 7 things a good supply chain plan generally consists of:

- Demand and forecasting assumptions: These specify how future demand is projected, which data sources are considered the most important, and how the teams make changes when the trends change. Transparent assumptions help to avoid confusion and make the planning process more realistic.

- Sourcing and supplier strategies: This section explains where materials come from, how suppliers are evaluated, and what backup options exist. It also defines response steps when lead times stretch or capacity tightens.

- Production schedules and capacity targets: Here, planners match production levels with demand forecasts, the availability of labor, and the limitations of the equipment, making sure that production is smooth and not forced.

- Inventory policies and stock positioning: Such policies define the quantity of inventory to be kept, the location of it, and the time of its replenishment, helping to control cash flow and the level of customer service.

- Logistics routes and transport planning: This covers warehouse flows, delivery paths, carrier choices, and timing expectations, keeping movement predictable and efficient.

- Contingency and response protocols: Well-defined escalation routes and backup actions equip teams to deal with the changes that may be caused by suppliers, weather, labor shortage, or sudden demand fluctuations.

- Roles, ownership, and communication channels: Clear accountabilities and reporting relationships help avoid duplication of efforts, delays, and misunderstandings between departments.

Execution is much easier when these components are all in place and work is supported by integrated business planning and capacity planning. Gradually, a regular framework together with supply chain planning best practices allows companies to maintain their alignment, flexibility, and operational assurance.

Conclusion

Good supply chain planning rarely gets applause, yet its impact shows up everywhere. Orders arrive when promised. Teams stay focused. Costs stay under control. Problems surface early, not at the last minute. That is the quiet power behind the importance of supply chain planning and control. It creates breathing room. It gives structure to uncertainty. It allows people to think ahead instead of scrambling. Trust is steadily built across teams, suppliers, and partners through consistent planning over time. Small tweaks strengthen the systems, and solid priorities are a source of energy for the operations to continue in the right direction. A successful plan creates its own momentum, and decisions become easier, quicker, and more assured.

Solicitar cotización de pedido al por mayor

Pedido simple, precios transparentes, entregado directamente a su puerta