Inventory Accuracy: Calculation, KPIs, Tips to Improve

Learn how to calculate inventory accuracy, track KPIs, fix stock errors, and improve control using proven methods, audits, and real-world tips.

200+ Käufer vertrauen Torg beim Sourcing

Inventory accuracy often shows up in the smallest details. A missing box here, a wrong count there, and suddenly plans start to wobble. Over time, those tiny slips grow into bigger problems, from delayed orders to awkward customer calls.

That's why knowing your way around inventory management techniques is a game-changer, especially as your operations scale up and new product lines start to roll out. This guide is going to walk you through some practical ways to keep tabs on your stock, catch any mistakes before they spiral out of control, and build some solid habits that make accurate inventory management second nature. Along the way, we'll also be talking about how a really strong inventory accuracy rate can help ease the tension between different departments, make sure your purchases are lined up with customer demand, and just generally keep daily operations running smoothly.

What Is Inventory Accuracy?

Inventory accuracy is how closely the records of stock levels reflect the actual stock at hand at any moment. It may sound so simple, but in everyday warehouse operations, small leaks can occur, and those leaks grow very quickly. A missed scan, a hurried pick, or a mislabeled carton, and suddenly, the numbers don't add up.

So, teams pause and ask, “Where did this go?” Over time, these moments affect planning, trust, and momentum. That’s why tracking the inventory accuracy rate matters, since it shows whether systems and real stock stay in step. When records reflect reality, purchasing flows better, fulfillment feels smoother, and decisions carry more confidence.

Of course, keeping on top of all this accurate inventory management takes a bit of patience and doesn't always come naturally — it's a case of learning to do the little things consistently, keeping routines steady and making sure you're not leaving anyone in the dark. In fact, it's a bit like keeping a room tidy. Leave it to itself for a day or two and before you know it, the place is a mess. But the other side of the coin is that if you stick with it, it's a whole lot easier to handle.

Why Is Inventory Accuracy Important?

The impact of inventory accuracy on daily operations than most teams realize. Only when stock data mirrors the actual situation can calm decisions be made, costs can be kept under control, and the service can be maintained at a dependable level. The advantages of accurate inventory count are very broad, ranging, covering aspects such as planning, fulfillment, finance, and customer experience.

Improved Customer Experience

When inventory accuracy stays high, customers feel the difference. Orders ship faster, stockouts fade, and delivery promises hold steady. Fewer cancellations mean fewer apologies.

Over time, trust grows, repeat purchases rise, and service teams handle fewer complaints. That reliability, built on accurate inventory management, quietly shapes loyalty, and brand trust.

Lower Operational Costs

When you manage your inventory accurately, you can cut down on excess stock, running out of stock situations, and keeping too much safety stock. By optimizing your inventory levels, you not only reduce the need for storage, but also make transport more predictable, and labor can be scheduled more efficiently.

Such efficiencies help in lowering your total operating costs, reducing inventory holding costs and reallocating capital for growth instead of using it to rectify inventory discrepancies and planning errors.

Improved Financial Reporting

Since inventory is usually a major component of working capital, its accuracy can significantly influence financial reporting. Accurate counting ensures a consistent inventory valuation method, reduces the need for inventory write-offs, and enhances the results of an audit.

Finance teams can see more clearly the relationship between costs, margins, and cash flow, meaning that they can create more accurate budgets, forecasts, and investment plans using reliable inventory data.

Stronger Planning & Forecasting

Having solid stock records really helps to get demand forecasting accuracy on track and lets you run some predictive analytics for inventory. At the end of the day, planners can actually trust the numbers, production schedules get a lot more stable, and when it comes to replenishing stock you can be one step ahead.

This all adds up to fewer last minute scrambles to correct stuff, better overall inventory control, and lets teams know when changes in demand are coming rather than getting caught out after the fact and having to deal with all the knock on effects on the service and cost side.

Operational Stability

When your inventory is accurate, it's like having a steady beat in your operations. Teams can schedule labour without too much worry, production plans are more consistent, and your logistics flows smoothly. With all the usual surprises getting less frequent, managers don't waste as much time trying to sort things out and can spend more time making things better.

All of this adds up to less stress, a lot more cohesion between departments, and supports performance across the whole business — in procurement, warehouse, manufacturing, and distribution — it just all gets a lot easier.

How to Calculate Inventory Accuracy

It's essentially about knowing how to calculate inventory accuracy when stock on the books matches the stock physically available. Besides being a straightforward calculation, the inventory accuracy KPI obtained has the power to completely change the daily routines, uncover potential risks, and even increase the efficiency of purchasing, warehousing, and fulfillment departments.

Key Methods for Calculating Inventory Accuracy

The standard formula for calculating inventory accuracy goes like this:

Inventory Accuracy (%) = (Correct Inventory Records / Total Inventory Records) * 100

As an example, let's say a warehouse that deals with consumer goods decides to do a cycle count on 1,200 SKUs. They end up ironing out discrepancies and get 1,140 records sorted out after scanning and re-counting them on the spot. This gives you:

(1,140 ÷ 1,200) × 100 = 95%

To some extent, the 5% difference here represents 60 inconsistencies that may not seem a lot now but steadily the little differences add up and create inventory discrepancies resulting in replenishment, picking speed, and deliveries to customers being impacted.

Another method compares physical stock directly against system data:

Inventory Accuracy (%) = (Physical Count ÷ System Count) × 100

Say a fashion retailer has an in-house system that claims they have 3,500 units of seasonal items in stock. Reality, however, reveals only 3,360 units when they physically count the stuff.

(3,360 ÷ 3,500) × 100 = 96%

This method is very effective for audits and cycle counts since it provides a transparent insight into how actual handling influences inventory management. A lot of teams keep records of both inventory accuracy formulas alongside each other to enhance inventory accuracy and locate the frequently problematic areas.

Quick checkpoints teams often monitor:

- Variance by product category

- Accuracy by storage zone

- Error frequency by shift

What Is a Good Inventory Accuracy Rate?

A good inventory accuracy rate usually bumps up against 95% and 99%. And you see that range popping up a lot because at this level, records stay reliable enough to guide everyday decisions. Not so high that teams get complacent, but reliable enough to give them a little breathing room to notice any gaps and work on tightening up routines. When you're sitting pretty above 95%, picking stock feels smoother, purchases happen without a hitch, and planners stop second-guessing their numbers. Plus it helps build trust across departments — because everyone is working from the same basic facts.

Push it up to 98% and things get even better. Orders move faster, stock buffers get smaller and forecasting gets a whole lot steadier. On the flip side, when you start to dip below 95% - small mistakes start to add up. Delays begin to happen, costs go up, and frustration spreads around. Very soon, without realizing it, the teams are spending more time solving problems rather than doing their work, and this is a very difficult cycle to get rid of.

Factors that Affect Inventory Accuracy

Inventory records shift for many small reasons, some visible, others quiet, yet all connected. From human movement to system design, each detail shapes daily results. Knowing which factors matter most helps teams focus effort, correct habits early, and protect results.

Human Handling

Hands on a hectic working day can move very fast and so small slips are made possible by such speed. For example, a missed scan, a picking done in a rush, or a packing box put in the wrong shelf can all quickly cause the counting to be out of sync. These inaccurate moments resulting from hours and shifts, when added together, are the cause of the inventory discrepancies which, in turn, disrupt the working of the different teams, delay the order processing, and eventually, erode the trust among the team members.

Data Entry Practices

Every stock move leaves a digital footprint, and small typing slips can quietly rewrite reality. A missed scan here, a late update there, and records start drifting. Soon, teams chase numbers instead of products, double-check orders, and redo simple tasks, while decision-making slows, tension rises, and daily momentum fades everywhere.

Storage Layout

A well-planned layout quietly keeps everything in motion. When shelves follow logic and pathways feel natural, items flow back into place without much thought. Yet when space feels cramped or unclear, habits slip, shortcuts appear, and products wander. Soon, searching replaces shipping, and time drains away during already packed workdays.

Technology Infrastructure

Systems shape speed. When tools connect smoothly, updates flow, scans sync, and teams see changes without delay. When platforms stay fragmented, data lags behind movement, errors hide longer, and real-time inventory tracking becomes unreliable, leaving managers to make choices using yesterday’s picture instead of today’s reality across shifting work demands.

Process Discipline

Routine anchors performance. Clear steps, shared standards, and simple checklists guide daily tasks. Without them, habits drift, shortcuts multiply, and small deviations feel harmless. Over weeks, those tiny breaks weaken inventory control, blur accountability, and make consistent results harder to achieve, even for experienced teams across changing operational demands daily.

Common Causes of Poor Inventory Accuracy

Small breakdowns in daily routines often cause stock records to drift. These issues rarely appear overnight. Instead, they build quietly through rushed handling, unclear systems, and uneven processes, until teams suddenly wonder, “How did things get this far?”

Receiving Errors

When trailers stack up and space tightens, teams switch to survival mode, and careful checks fade. One unverified pallet slides through, then another, until records drift away from reality. Soon purchasing reacts, shelves overflow, and planners scramble, tracing problems back to a single rushed unload that quietly rewrote the numbers.

Picking Mistakes

Speed sets the tone on busy warehouse floors, yet haste often clouds attention. When shelves look alike and time feels tight, hands move before eyes confirm. A small slip becomes two, then three, and soon teams circle back, retracing steps, reopening cartons, and fixing orders that once seemed finished.

Returns Mismanagement

Returns arrive unpredictably, often mixed with fresh stock and outgoing shipments. When they skip proper inspection and re-entry steps, they sit in limbo. That gray area distorts availability, delays restocking, and clouds sales data, making teams unsure what can ship today and what still needs processing before rejoining active inventory.

System Sync Delays

When physical movement outpaces system updates, records lag behind reality. Scans wait to upload, confirmations queue, and screens show outdated numbers. That time gap invites confusion, duplicate work, and wrong decisions, especially during peak hours, when teams rely heavily on immediate visibility to guide picking, packing, and replenishment actions.

Poor Documentation

Clear records act like breadcrumbs through daily operations. When those trails fade, confusion steps in. A missing note here, an unclear entry there, and soon no one knows which path was taken. Teams start piecing together events, slowing reviews, stretching audits, and turning simple questions into long, energy-draining hunts.

Inventory Accuracy vs Inventory Turnover

Inventory accuracy and inventory turnover are two metrics that focus on completely different aspects of stock management. Inventory accuracy essentially assesses the degree to which the records correspond to the facts on the ground, while inventory turnover is indicative of the rate at which the products are flowing through the system. The two, combined, provide a more comprehensive view. If isolated, they may give rise to contradictory indications. Good results require both to be in harmony.

Inventory Accuracy: Trust in the Numbers

Inventory accuracy builds confidence across daily operations. When records mirror reality, teams stop second-guessing and start moving forward. Orders flow, restocking stays predictable, and planning gains clarity. Fewer checks mean fewer delays, while steady data reduces stress, sharpens focus, and supports decisions that feel grounded instead of reactive throughout shifting work cycles.

Inventory Turnover: Speed of Stock Movement

Inventory turnover shows how quickly products leave shelves and return again. When this rhythm feels steady, cash circulates, stock stays fresh, and planning stays clear. Still, moving too fast without control invites mistakes, late reorders, and shortfalls. A measured pace keeps teams calm, customers satisfied, and operations aligned throughout daily cycles.

Key Differences Between Inventory Accuracy and Inventory Turnover

Aspect | Inventory Accuracy | Inventory Turnover |

|---|---|---|

Core Focus | Data correctness | Stock movement speed |

Primary Purpose | Ensure records match physical stock | Measure how quickly inventory sells |

Main Benefit | Builds trust, reduces errors, supports planning | Improves cash flow, limits overstock |

Key Risk When Low | Mismatches, delays, confusion | Excess stock or slow-moving items |

Impact on Decisions | Guides purchasing and fulfillment accuracy | Guides replenishment timing and volume |

Operational Signal | Process reliability | Market demand and sales efficiency |

Best Used For | Audits, planning, and stock control | Sales strategy and supply planning |

When the two metrics align, the operational activities seem to be steady, predictable, and resilient. Accuracy is what maintains the cleanliness of the data, whereas turnover enables the business to be flexible. In unison, they give the teams the ability to balance fast pace with control, which is generally the point where sustainable performance exists.

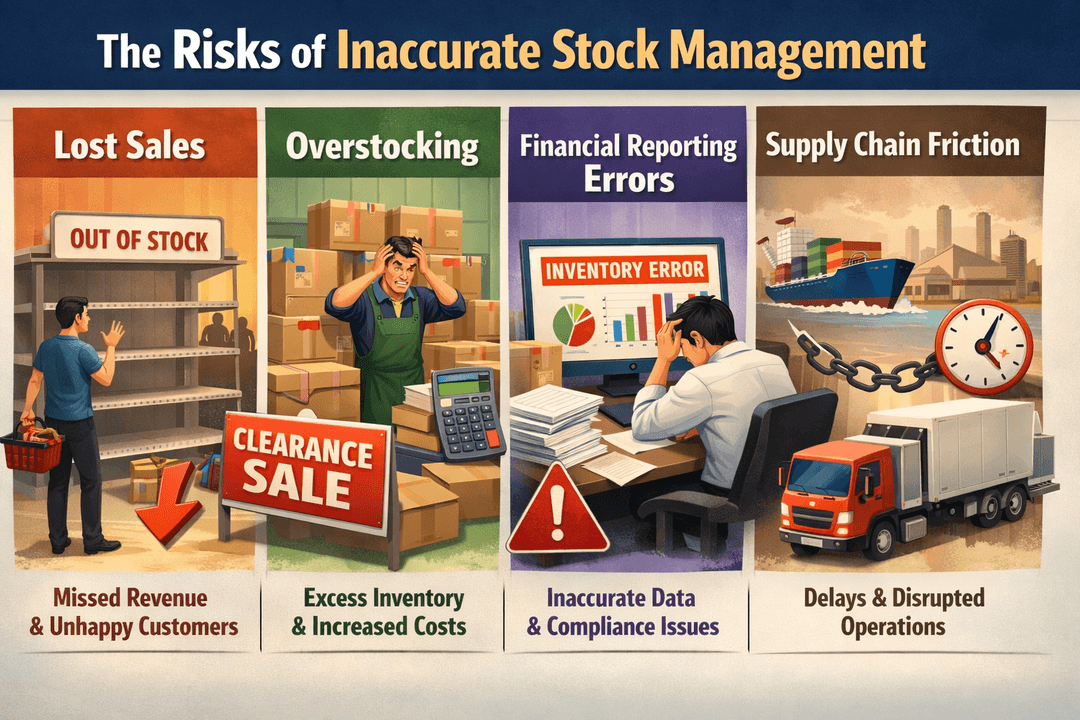

The Risks of Inaccurate Stock Management

When stock records diverge from reality, the whole operation feels the pressure. At first, a minor discrepancy is only a couple of changes in the production schedule, budget, and expectations, but it becomes a new constellation of changes each time. It is hardly noticeable, but these secret shifts over the years affect the way teams collaborate, the customers' reactions, and the leaders' growth strategies.

Lost Sales

An order at the status of "ready to ship" might encounter a delay in the fulfillment process. Customers are left hanging, they keep refreshing the tracking pages, and slowly, their faith in promises erodes. Every postponement further damages trust that buyers had, thus they become inclined to choose other items that can be delivered faster. Gradually, these silent changes in customer behavior will lead to the loss of their loyalty and their purchasing habits becoming less frequent, and so the revenue decreases and the teams have to work harder for the opportunities that used to come effortlessly.

Overstocking

Underreported stock nudges teams toward caution, so orders go out early and often. Pallets stack up, walkways narrow, and space becomes scarce. Money settles into items that move slowly, limiting options elsewhere. Before long, discounts appear, pressure builds, and clearing excess takes more effort than preventing it ever did.

Production Delays

Manufacturing is all about timing. If the materials aren't available, everything gets messed up. The workers stop, the machines stay silent, and the deadlines get pushed. This disturbance affects the sequences of shipping, the employees, and the suppliers. In the long run, these delays break down team spirit, raise the cost of overtime, and change the once predictable processes into a never-ending series of adjustments.

Financial Reporting Errors

When inventory figures go down, financial statements become unstable and projections become shaky. Executives stop, look at the graphs again, question the patterns, while auditors investigate more and budgets become tighter. Eventually, distorted data hampers evaluations of performance, deteriorates planning, and makes long-term strategy a hesitant exercise influenced by uncertainty rather than clarity.

Supply Chain Friction

It is the partners who experience the brunt of the problem first whenever the inventory data is unstable. A carrier may show up too early or too late, a crew may get an excuse to be idle, and loading plans change in the middle of the process. There would be more calls, a pile of emails, and the patience that can only be stretched so far.

How to Improve Inventory Accuracy

One of the keys to making a lasting improvement is by cultivating steady habits, clarifying ownership, and even getting tools that facilitate daily work. When all three, people, routines, and systems, are synchronized, not only do stock records remain accurate, but errors are also identified at a much faster rate, while the teams have the confidence to make the right decision at every task throughout their shift.

Here are 6 tips on how to improve inventory accuracy:

1. Standardized Operating Procedures

Well-defined operating steps eliminate uncertainty in daily activities. If receiving, storage, picking, and shipping share common routines, errors lower drastically. Onboarding newcomers becomes quicker, seasoned employees remain on the same page, and interactions between different sections get easier. Gradually, regularity becomes the norm instead of disorder, enabling staff to manage hectic times efficiently without compromising the quality or supervision of each and every work area.

2. Staff Training

Training builds awareness, not just skills. When teams understand why every scan, count, and entry matters, habits change. Care replaces speed alone. Step by step, mistakes lessen, assurance becomes higher, and responsibility is shared, resulting in the transformation of ordinary work into meaningful deeds that safeguard data quality and consequently, trust is built not only among departments but also up to the leadership teams.

3. Cycle Counting

Frequent counts catch small slips before they grow. Instead of waiting months, teams review sections weekly or daily. That rhythm exposes weak spots, sharpens routines, and builds steady discipline. Over time, minor fixes prevent major disruptions, helping stock records stay aligned with reality without halting normal operations or fulfillment flow.

4. Technology Integration

Modern tools have significantly reduced the time between performing an action and recording it. Devices such as scanners, RFID, and cloud systems are updating the stock levels right away, decreasing delay and misunderstanding. Also, as technology automates more processes, transparency enhances, the mistakes become more evident quickly, and the staff get to spend less time on reworks, and this makes them more able to concentrate on efficiency, quality of service, and better daily planning.

5. Data Visibility

Clear dashboards help to transform raw data into actionable insights. When alerts point out significant changes, teams react quickly to prevent problems from escalating. This consistent feedback cycle helps to maintain concentration, encourages the making of wise decisions, and creates a common understanding which is crucial for keeping everyone on the same team, being proactive, and having confidence even in rapidly changing operational situations across customer demand fluctuations.

6. Continuous Process Reviews

By regularly reviewing, routines are always fresh. The team takes time to stop, think, and change steps that are not working or are too slow. After a while, the bottlenecks become less, the shortcuts vanish, and the workflows change naturally. A continuous improvement mentality like this helps to maintain the correctness, ensure the good performance, and keep the operations adaptable as the amount of work, type of goods, and customer demands change.

Inventory Accuracy KPIs and Metrics to Track

Efficient inventory management is largely a matter of well-defined measurement mechanisms. By monitoring the appropriate indicators, the teams not only get to see the trends but also identify the potential risks at an early stage and so, improvement becomes intentional. These metrics essentially convert daily operations into tangible insight so the decisions that are made across the fields of purchasing, warehousing, fulfillment, and financial planning are more informed.

Inventory Accuracy KPI

This KPI gauges the degree of matching between the records and the actual stock physically present by the inventory accuracy formula: (Correct Records ÷ Total Records) × 100.

Several international retail chains declare their audited facilities to have an accuracy level of over 97%, helping them to have a seamless fulfillment process, less disputes, and timely reconciliation, particularly their multi, location warehouse networks which handle thousands of transactions every day.

Order Fulfillment Rate

This metric measures the percentage of orders shipped correctly and on time to total orders (Orders Shipped Correctly and On Time ÷ Total Orders) × 100. Leading logistics companies disclose a delivery performance of over 95%. Their reliable inventory data has enabled them significantly to improve the speed of order picking, the accuracy of deliveries, and the overall customer satisfaction.

A very high order fulfillment rate means that almost no orders need to be returned or redone, there are fewer complaints handled by customer services, and most importantly, the brand trust is preserved for the long run.

Cycle Count Variance

Cycle count variance measures |System Quantity – Physical Count| ÷ System Quantity × 100.

Large distribution centers often report under 2% variance after adopting daily zone counts. Low variance signals disciplined handling, accurate scanning, and tight process control, allowing faster issue resolution before discrepancies expand into larger operational disruptions.

Shrinkage Rate

Shrinkage can be determined by (Recorded Inventory – Actual Inventory) / Recorded Inventory x 100.

A recent National Retail Security Survey revealed that retail shrinkage in the U.S. has been around 1.6% of sales on average. Keeping an eye on this indicator allows for the separation of theft, damage, and handling loss, ensuring margins are not compromised and internal controls are made more robust.

Stock Level Optimization Metrics

These metrics track stockout frequency, overstock ratios, and carrying cost percentages. Global supply chain studies show companies maintaining stock availability above 97% while keeping excess inventory below 10% achieve stronger cash flow. Balanced stock levels support faster turnover, lower holding costs, and steadier service performance across fluctuating demand cycles.

Inventory Accuracy Challenges and Solutions

Good operations also face difficulties. The factors like fluctuating consumer demand, expanding product range, and changing technology stir up the pressure. The happier the teams are with the identification of these challenges at the earliest, the less disruptive the solutions will be. Little changes, constant sharing of information, and tolerant implementation can let the changes go unnoticed, keep the accuracy intact and, at the same time, minimize the impact on the working routine, reducing the occurrence of problems and the level of stress.

High SKU Complexity

As product ranges expand, locating items becomes harder. Similar packaging, dense shelving, and overlapping categories slow picking and increase errors. Clear zoning, logical slotting, and simple barcode logic restore order. Over time, navigation improves, search time drops, and teams regain confidence, even as catalogs continue growing across multiple storage locations.

Seasonal Volume Surges

Peak seasons stretch capacity, attention, and patience. Extra orders flood in, routines tighten, and mistakes rise. Temporary staffing, shorter shifts, and targeted cycle counting work together to stabilize the flow of activity. When properly paced and planned, the teams make the high volume of work manageable without letting accuracy fall. So they intensify periods by controlled bursts rather than these being chaotic scrambles that drain resources.

Technology Adoption Barriers

New systems often meet hesitation. Familiar screens feel safer than unknown tools. Gradual rollouts, hands-on demos, and open feedback ease transitions. When teams see real gains in speed and clarity, confidence grows. Slowly, resistance softens, allowing technology to support work instead of complicating already busy operational rhythms.

Process Resistance

Change unsettles habits. When routines shift, uncertainty appears. Clear explanations, steady leadership, and visible progress help calm concerns. By way of small wins, trust is created. After a while, teams see the results, get used to the changes, and offer suggestions, so that resistance is turned into ownership which helps to build consistency, accountability, and long-term performance, not only in departments, but also across them.

Inventory Accuracy Audit Checklist

Everyone knows that a smoothly conducted audit is a comforting check-up rather than a test. It reveals problems that were kept in the dark, explains areas of noncompliance, and provides the team with a clear and sensible plan. A well-prepared list of things to check can keep the inventory accuracy audit process consistent, deep, and beneficial from one location, shift, and report cycle to another.

✅ Thoroughly verify all documentation related to the dispatch and receipt of items

Compare receiving logs, packing slips, and shipping documents against system records to check that the quantity, product codes, and time of the transactions agree as even minor discrepancies in paperwork can very subtly lead to stock data being wrong.

✅ Test barcode scanning and data capture tools

Scan items across different zones and shifts to ensure devices read consistently, upload promptly, and reflect real movement without delays, missed entries, or repeated errors.

✅ Evaluate storage labeling, layout, and flow

Check the condition of shelf labels; are they still readable? Also, consider whether location arrangements make sense and if pathways promote putting things back in the right places, minimizing the chances of items getting into the incorrect areas.

✅ Run targeted physical spot counts

Identify the SKUs that are of high value, have a high turnover rate, or are frequently causing issues, and then undertake a physical check of the shelf stock by comparing it with system records to discover the trends instead of just the errors.

✅ Confirm system connections and data sync

Ensure that the warehouse systems, ERP platforms, and sales channels are synchronized and refreshed almost in real time, avoiding delays which lead to distorted decision, making, and planning inaccuracies.

✅ Observe staff routines and compliance

Watch the processes of receiving, picking, and packing in order to be sure that the teams are following the procedures that have been laid down consistently, even during periods of high workload.

✅ Analyze variance trends over time

Keep a record of continuously recurring mismatches to figure out their main causes, the effects of different seasons, or points in the workflow that get too much pressure are worthy of further investigation.

✅ Inspect security measures and access controls

Check camera coverage, the location of restricted zones, and access rights to minimize the possibility of unauthorized handling and reduce theft, damage, or loss through accidents.

Altogether, these activities help to clear up what is going on, create a sense of responsibility, and lead to such targeted changes which increase the inventory's long-term trustworthiness.

Conclusion

Reliable inventory records dictate the level of a business' efficiency, from daily picking to forward planning. It is when teams stick to inventory accuracy best practices that the tiniest of changes accumulate, resulting in more stable working conditions and more informed decisions. Knowing how to measure inventory accuracy directs attention, and so routine audits become a source of valuable information. With time, trust supersedes doubt, efficiency takes over from hesitation, and strategy is based on facts rather than assumptions. In that kind of place, growth seems controlled and not too overwhelming, and resilience is something that comes very easily to an organization so it stays balanced during change, uncertainty, and shifting market demands without losing its momentum or clarity.

FAQs

What is the ideal inventory accuracy rate?

The ideal inventory accuracy rate is 95 - 99% for most industries. This level ensures reliable fulfillment, confident planning, and stable reporting. If you maintain the accuracy level within this range, you will have less disruptions, fewer costly errors, and the team would be able to operate smoothly even during high demand and complicated cross-departmental operational cycles.

How often should inventory be counted?

Inventory can be counted weekly or monthly through cycle counting programs. Regular counts help to detect the errors early and keep the records from drifting while on the other hand, annual stocktakes are more disruptive. Gradually, this consistent pattern of behavior becomes a habit, makes the routines sharper and the stock records always reflect the reality of the daily operations.

Can inventory accuracy be 100%?

Inventory accuracy can get very close to 100%, however, it is very rare to be able to keep it at a constant level due to daily stock movement, manual handling, and system delays. Strong automation, disciplined processes, and frequent audits help keep accuracy extremely high.

How to maintain inventory accuracy?

Inventory accuracy is achieved and maintained over time through uniform procedures, periodic stocktaking, well-trained personnel, and efficient hardware and software for inventory tracking. These measures enable identifying the mistakes at the earliest stage, increase work discipline, and hence, updating the stock books remains consistent with the actual stock through all stages of operations.

Anfrage für Großbestellung

Einfache Bestellung, transparente Preise, direkt an Ihre Tür geliefert